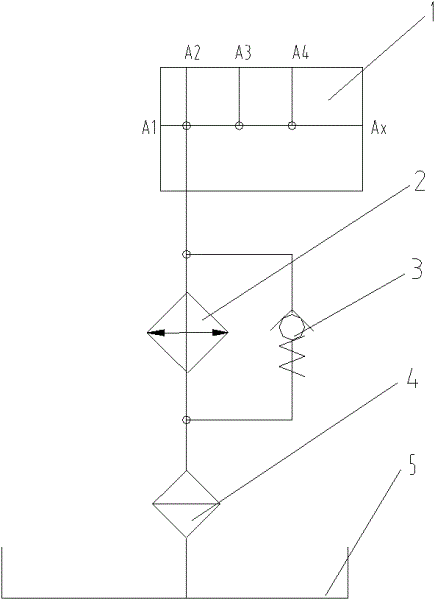

Hydraulic system flow collector with bypass function

A hydraulic system and fluid collector technology, which is applied to fluid pressure actuation system components, fluid pressure actuation devices, servo motor components, etc., can solve problems such as cumbersome installation and pipe joint leakage, reduce hydraulic system leakage, simplify The effect of piping connections

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

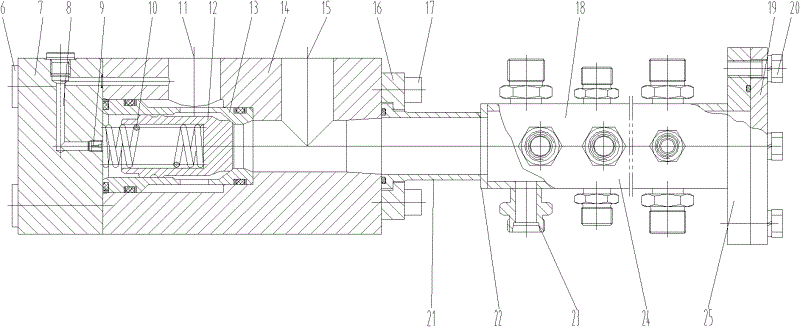

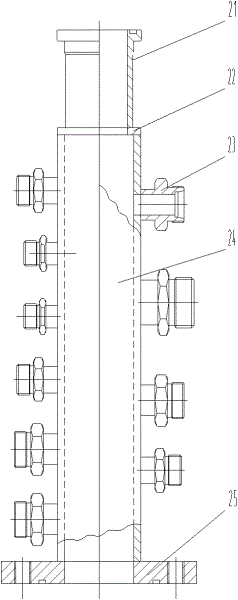

[0012] In order to further understand the technical content, characteristics and effects of the present invention, the following examples are listed hereby, and detailed descriptions are as follows in conjunction with the accompanying drawings:

[0013] Refer to attached figure 2 , a hydraulic system collector with a bypass function, which is characterized in that it is composed of a collector 18, a flange cover 19 and a three-port safety valve, wherein the collector is provided with a joint body 23 for Connected to the oil return and drain of the hydraulic system, one end of the collecting pipe is connected to the oil inlet of the three-oil port safety valve, and the other end of the collecting pipe is blocked by the flange cover plate; the three-oil port safety valve The valve includes a cover plate 7, a damping plug 9, a spring 10, a valve core 12, a valve sleeve 13, and a valve body 14, wherein the cover plate is fixed on the valve body by screws, the valve sleeve is tigh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com