Led lamp

A technology of luminescent material and lamp body, applied in the direction of semiconductor device, lampshade, light source, etc. of light-emitting element, which can solve the problems of different shapes and unfavorable customer acceptance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

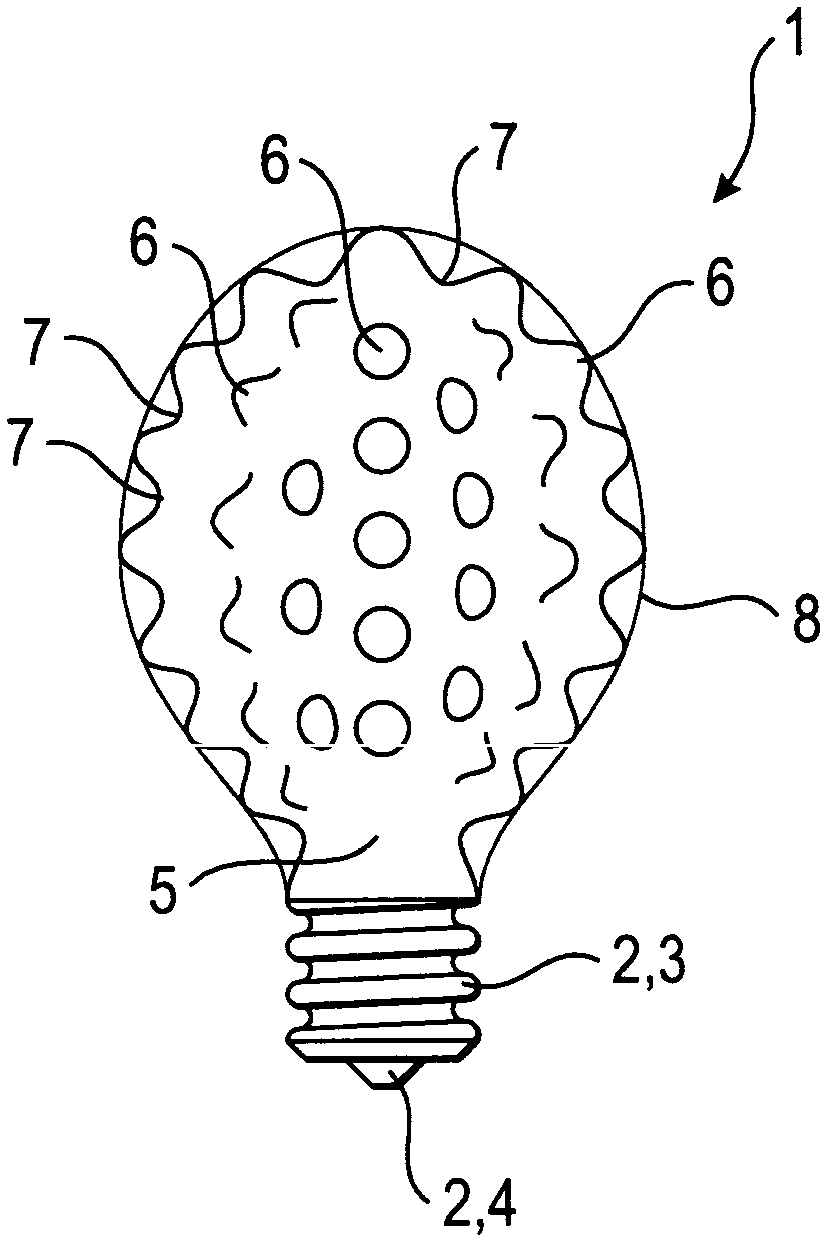

[0075] figure 1 Shown is an LED lamp 1 having an LED module with a carrier (not shown) and a base connected to the carrier or a base 2 in the form of an Edison base with an external contact 3 and a foot contact 4 . The support is equipped with at least one LED and circuit components (not shown) arranged between the at least one cap and the at least one LED for driving the LED. Furthermore, the LED lamp 1 has a lamp body 5 with a recess (not shown) for accommodating at least that part of the carrier carrying the at least one LED. The lamp body 5 has a surface structuring for cooling the LED lamp 1 by heat convection. The surface structuring comprises a plurality of protrusions 6 or recesses 7 which are round in plan view. They are distributed largely evenly over the surface.

[0076] Despite the structuring, the shape of the illuminant or lamp body 5 or of the LED lamp substantially corresponds to the shape of a conventional incandescent light bulb. Outline 8 is drawn for ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap