Clamp for crop stem bending test

A bending test and fixture technology, applied in the field of crop stem bending test fixtures, can solve problems such as inability to effectively fix plant stems, inability to meet stem bending test requirements, and inability to effectively test lodging resistance mechanical strength of node stems. , to reduce crushing, improve pullout resistance, and increase contact area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

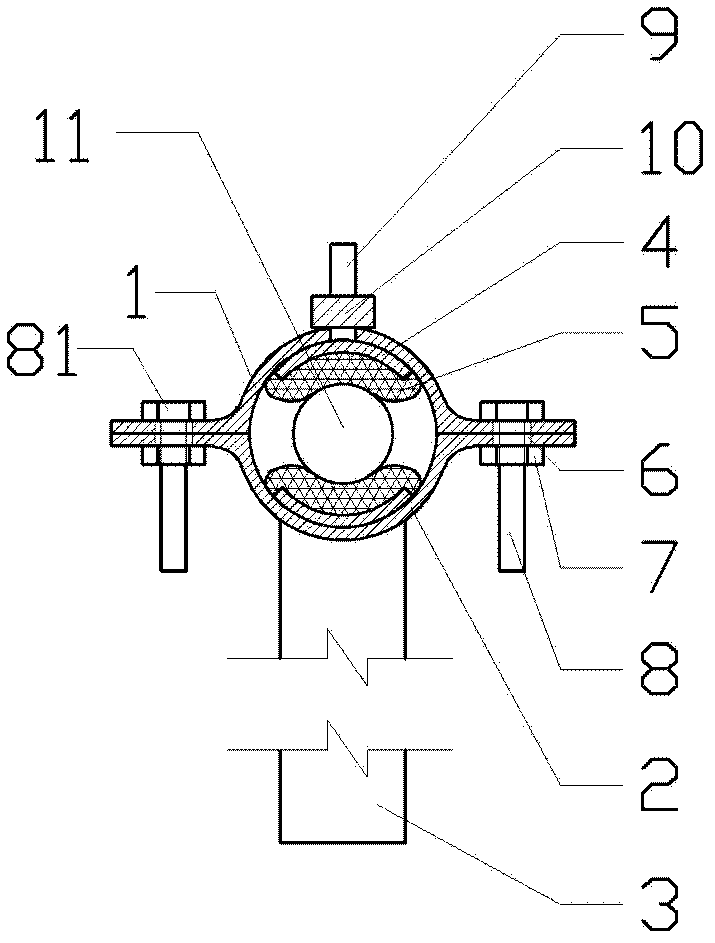

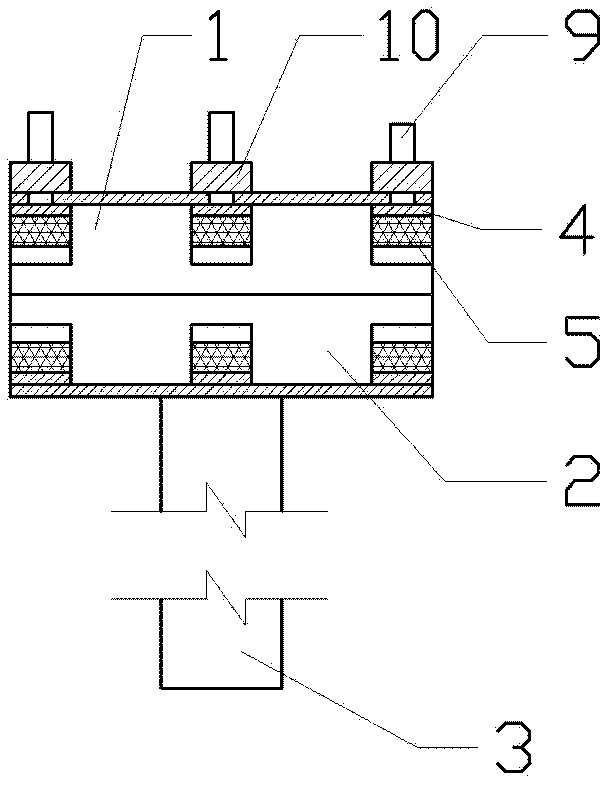

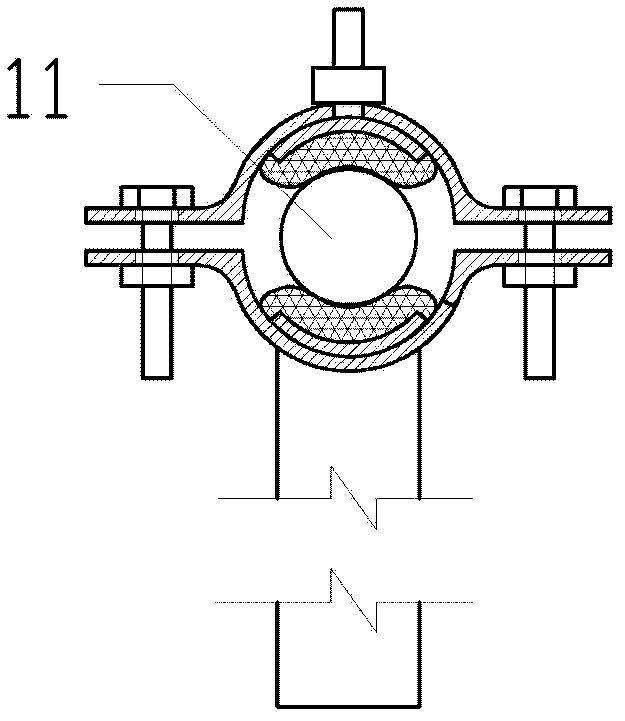

[0032] The present invention will be further described below in conjunction with drawings and embodiments.

[0033] As shown in the figure, the fixture includes a clamp handle 3 and a fixed chuck with a circular clamping cavity. The fixed chuck is composed of a semi-circular upper chuck 1 and a semi-circular lower chuck 2. The lower chuck 2. The clamp handle 3 is fixed at the bottom, and the two sides of the upper chuck 1 and the lower chuck 2 are provided with perforated 6 connecting ears 7. The upper chuck 1 and the lower chuck 2 are fastened through the chuck fixing hole 6 bolts, and other clamps can also be used. The detachable connection is fixed connection.

[0034] The fixture is also provided with a pushable arc-shaped inner chuck 4, the inner chuck 4 is arranged in the circular clamping cavity, and its top is fixed vertically upward with a distance-adjusting screw 9, and the distance-adjusting screw 9 passes through the fixed chuck The hole provided on the top is thr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com