Internal pressure compensation device for oil-impregnated paper insulating sleeve

A compensating device, a technology for internal pressure, applied in the direction of transformer/inductor cooling, etc., can solve problems such as uncontrollable and affecting the performance of insulating oil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

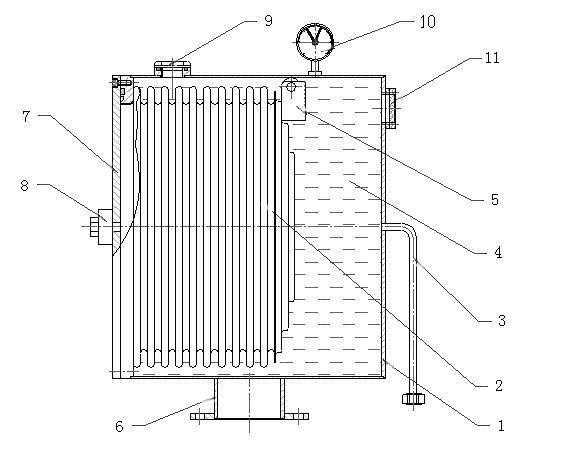

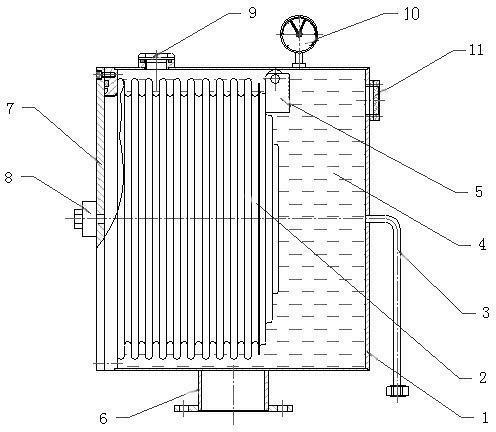

[0012] figure 1 This is a preferred embodiment of the present invention. The present invention will be further described below with reference to the accompanying drawings: Among them, 1 compensation device housing, 2 corrugated expansion tube group, 3 oil connection pipe, 4 oil chamber, 5 movable support wheel, 6 base , 7 end plates, 8 pressure regulating valves, 9 oil injection valves, 10 pressure indicating alarm devices, 11 observation windows.

[0013] according to figure 1 , The internal pressure compensation device of the oil-paper insulated casing is installed outside the casing body, and is connected to the internal pressure of the casing through the oil connection pipe 3, which includes the base 6, the compensation device housing 1, and the compensation device housing 1 The oil chamber 4 is characterized in that: the compensation device is provided with a corrugated expansion tube group 2 that can be expanded and contracted in parallel, and the oil chamber 4 is located ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com