Underwater towed vehicle automatic detaching apparatus

An underwater tow body, automatic release technology, applied in the directions of underwater operation equipment, transportation and packaging, ships, etc., can solve the problems of high destructiveness, low reliability, and inability to play a protective role.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to better understand the technical solution of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

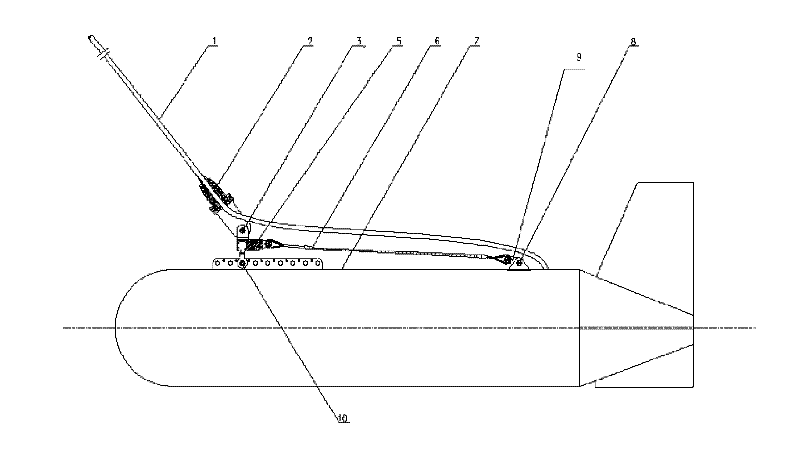

[0019] Such as Figure 1 to Figure 6 The device includes a tow cable 1, a load-bearing joint 2, a joint pin shaft 3, a universal connector 5, a protection cable 6, a shackle pin shaft 8, a shackle body 9, and a breaking pin 10;

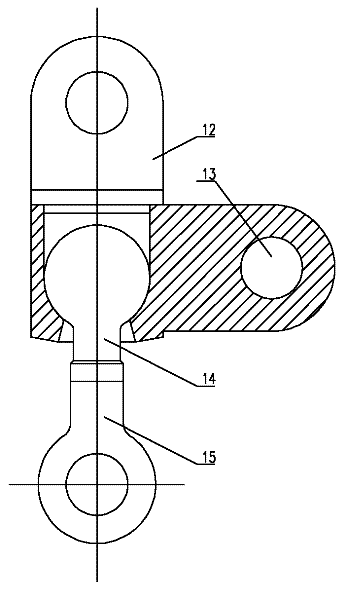

[0020] Wherein the universal connector 5 is composed of ear plate I 12, ball hinge 15, ball head 14 and ear plate II13, ear plate I 12 is welded to ear plate II13, ear plate II13 is welded to ball head 14, and ball hinge 15 can be Free rotation; ear plate I 12, ball hinge 15 and ear plate II13 each have a connecting hole;

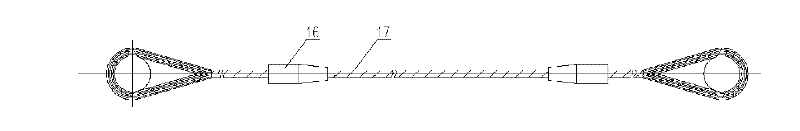

[0021] The protection cable 6 is made up of a steel wire rope 17 and two connectors 16; the two ends of the steel wire rope 17 are respectively bent into a ring and fixed and compressed with the connector 16; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com