Cable laying method and bracket thereof

A cable laying and cable technology, which is applied in the field of cable laying and its support, can solve the problems of difficulty and large longitudinal induced voltage of the cable aluminum sheath, and achieve the effects of reducing induced voltage, good energy saving effect, and reducing civil construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing.

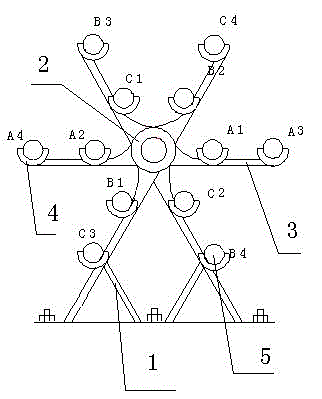

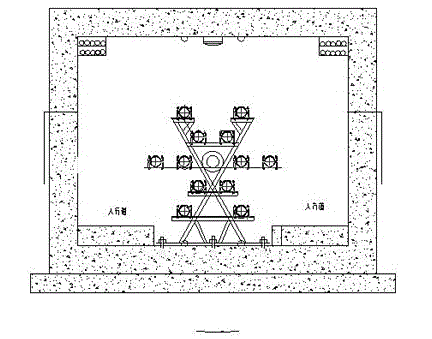

[0024] like figure 1 As shown, the cable laying bracket of the present invention includes a bracket main body 1, and twelve cable support seats 2 and a central ring 3 arranged on the support main body 1, and every three cable support seats 2 form a group, and the cable support seats 2 Arranged along the circumferential direction of the concentric circles, and the same group of cable support seats 2 are located on the same circumference, and the angle between them is 120°; the central ring 3 is located at the center of the aforementioned concentric circles; the concentric circles include inner rings And the outer ring, six cable support seats 2 are respectively established on the inner and outer rings, and are evenly arranged along the inner and outer rings.

[0025] When in use, four sets of three-phase cables can be placed on the cable laying bracket to place the cables 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com