Anti-torsion cable

A technology for cables and insulated wires, applied in the field of torsion-resistant cables, which can solve problems such as deformation of cable conductors, affecting cable performance, and breakage, and achieves the effects of less production equipment, less twisting procedures, and less production space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

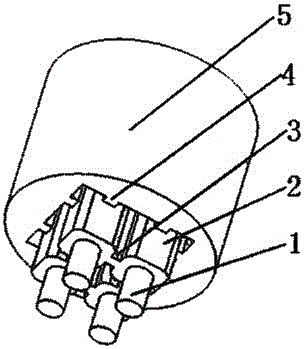

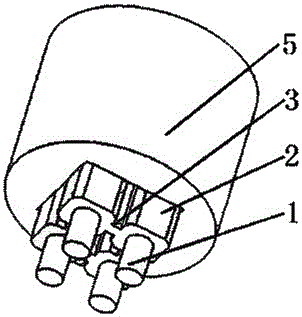

[0030] please see figure 1 with figure 2 A twist-resistant cable, which includes four insulated wires, a sheath layer 5 that covers the insulated wires, and the insulated wires are composed of a conductor 1 and an insulating layer 2 that covers the conductor, and is characterized in that the adjacent insulating layers are connected by connecting ribs 3; the sheath layer and each insulated wire are in double-sided contact; there are two connecting strips 4 between the sheath layer and each insulated wire; the inner surface of the sheath layer and Not the sides of a cylinder but four planes; the insulated wire is a cuboid with notched corners.

Embodiment 2

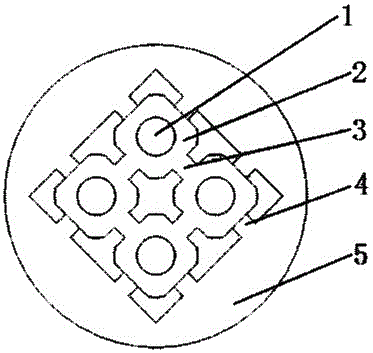

[0032] please see image 3 with Figure 4 , a twist-resistant cable, which includes four insulated wires, a sheath layer 5 covering the insulated wires, the insulated wires are composed of a conductor 1 and an insulating layer 2 covering the conductor, and is characterized in that the adjacent insulating layers They are connected by connecting ribs 3; the sheath layer and each insulated wire are in double-sided contact; the inner surface of the sheath layer is not the side of the cylinder and is four planes; the insulated wire is a rectangular parallelepiped with missing corners .

Embodiment 3

[0034] please see Figure 5 with Image 6 , a twist-resistant cable, which includes three insulated wires, a sheath layer 5 covering the insulated wires, the insulated wires are composed of a conductor 1 and an insulating layer 2 covering the conductor, and is characterized in that the adjacent insulating layers The space is connected by connecting ribs 3; the sheath layer is in double-wire contact with each insulated wire; the inner wall or inner surface of the sheath layer is not the side of the cylinder but has three planes; the insulated wire is in the shape of a cylinder .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com