Bent member, and device and method for manufacturing same

一种制造装置、制造方法的技术,应用在运输和包装、薄料处理等方向,能够解决很难坯料加工、设备成本上升、加工坯料裂纹等问题,达到低成本、低成本化轻量化的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0074] Hereinafter, the best mode for carrying out the present invention will be described with reference to the drawings. In the following description, the following case is taken as an example, that is, the curved member manufactured by the present invention is a hollow member made of steel and has a rectangular cross section as a blank, and is used as a strength member and a reinforcement member in automobiles and various machines. or structural members.

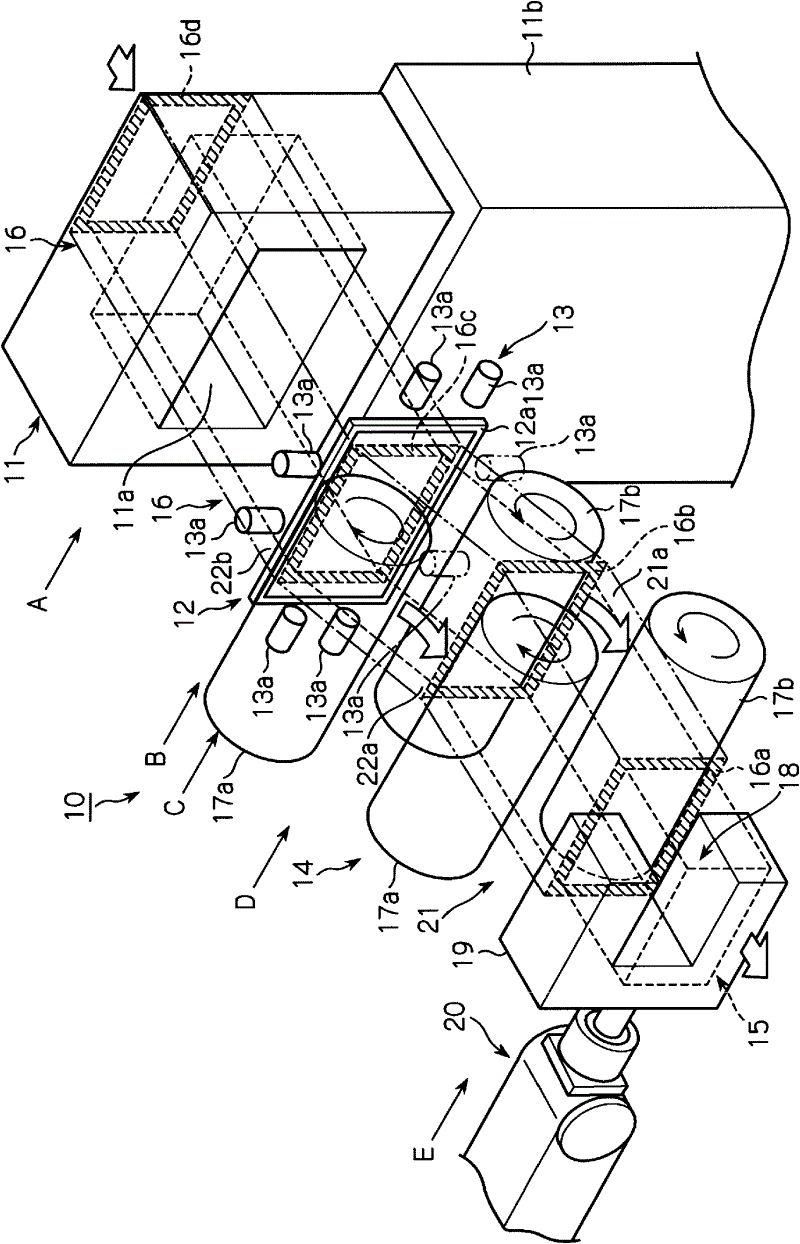

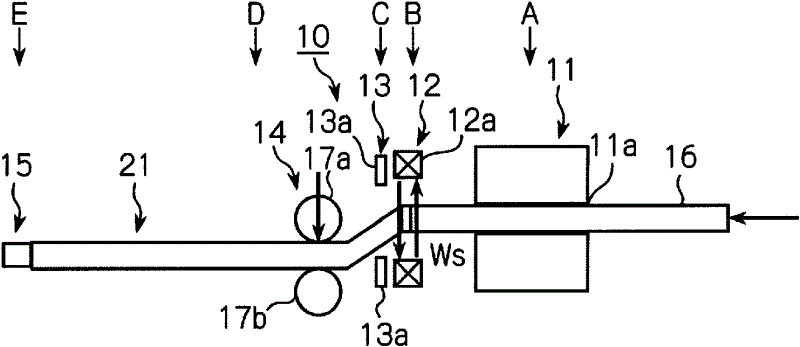

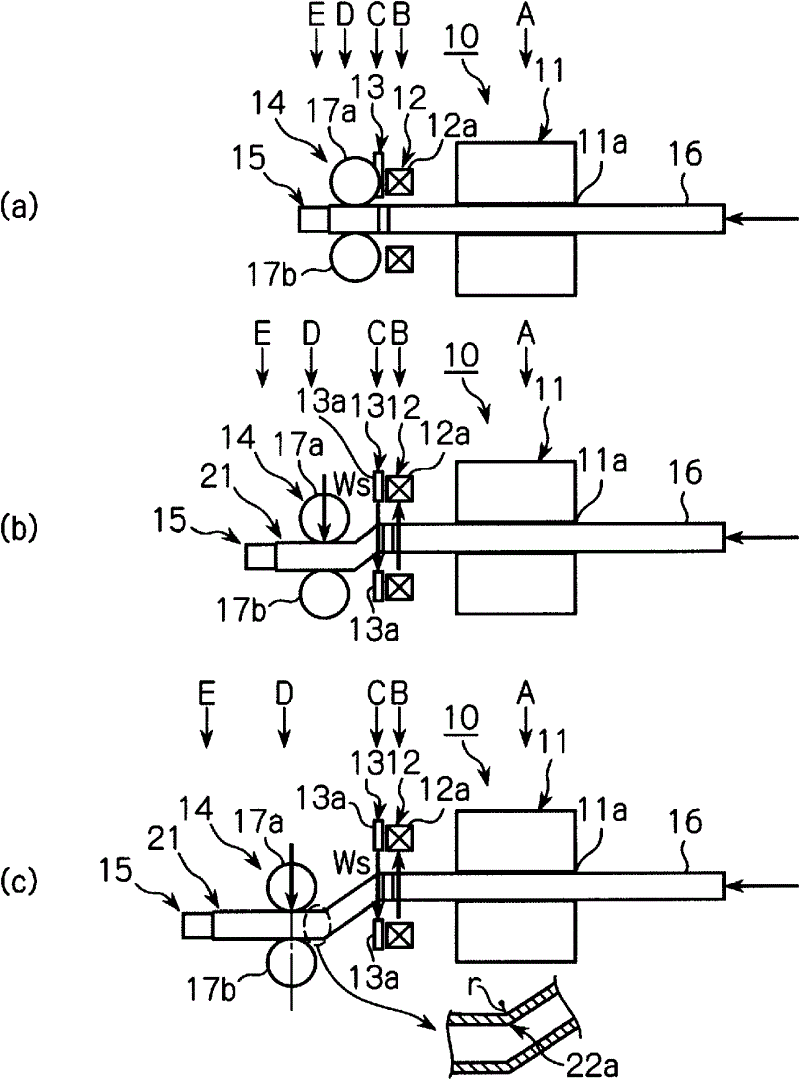

[0075] figure 1 It is a perspective view which partially simplifies and omits the structural example of the manufacturing apparatus 10 of this invention, and shows it see-through. in addition, figure 2 is an explanatory diagram schematically showing a configuration example of the manufacturing apparatus 10 .

[0076] Such as figure 1 , figure 2 As shown, the manufacturing device 10 has a first supporting device 11 , a heating device 12 , a cooling device 13 , a shearing force applying device 14 , and a second sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com