Milling mechanism of pipe cutting machine

A pipe cutting machine and milling technology, which is applied to metal sawing equipment, sawing machine equipment, metal processing equipment, etc., can solve the problems of high cutting noise, low safety, and many incision burrs, and achieves low vibration and extended saw blades. Longevity, smooth incision without burr

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

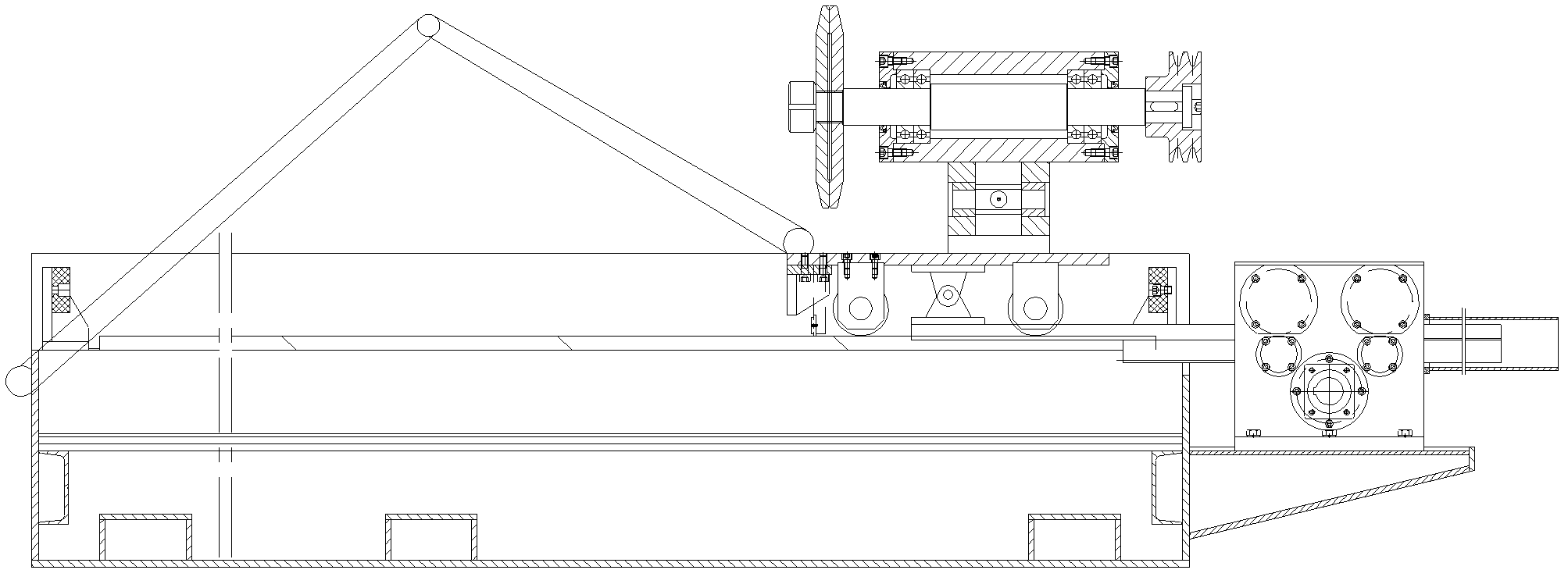

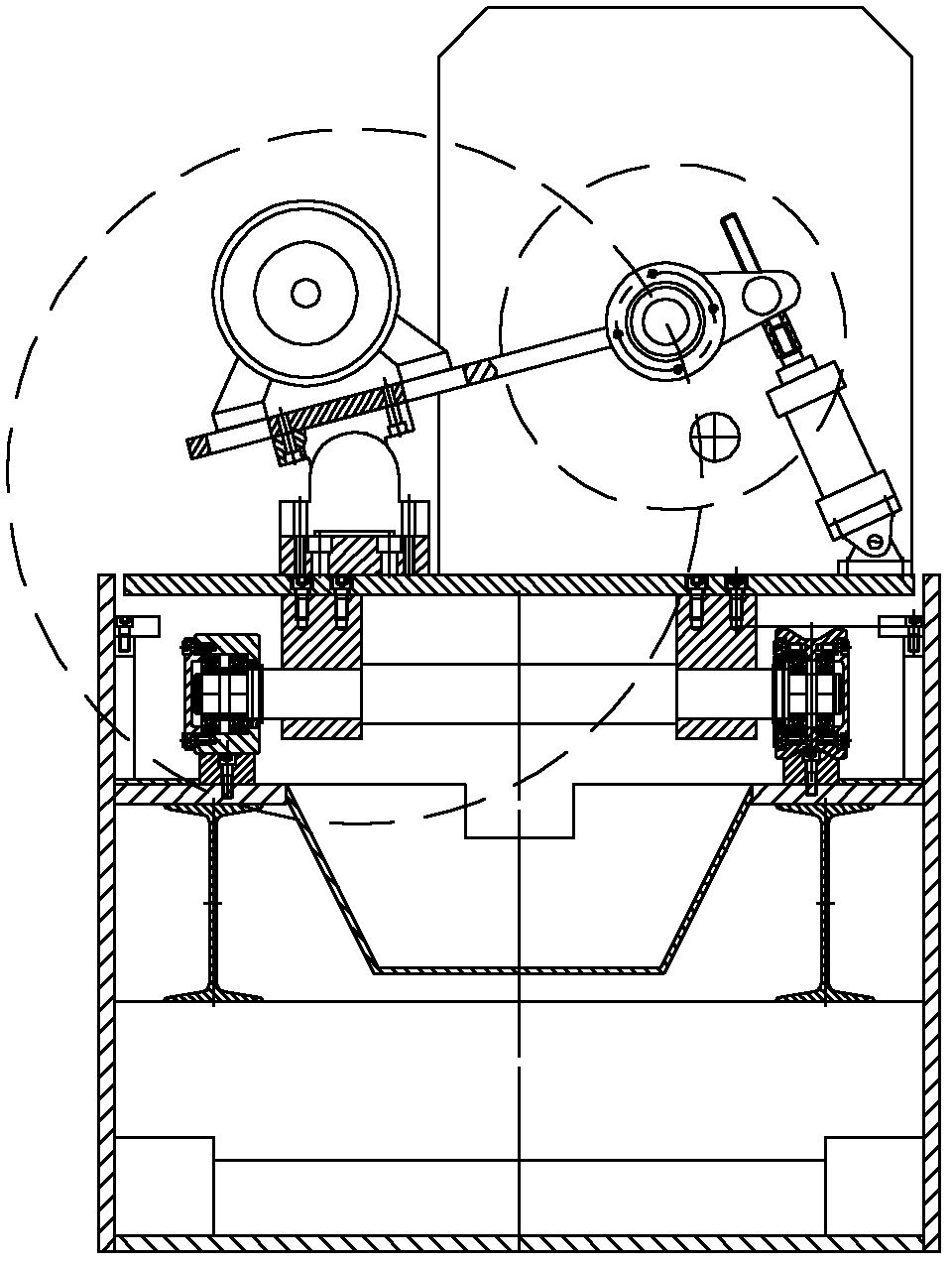

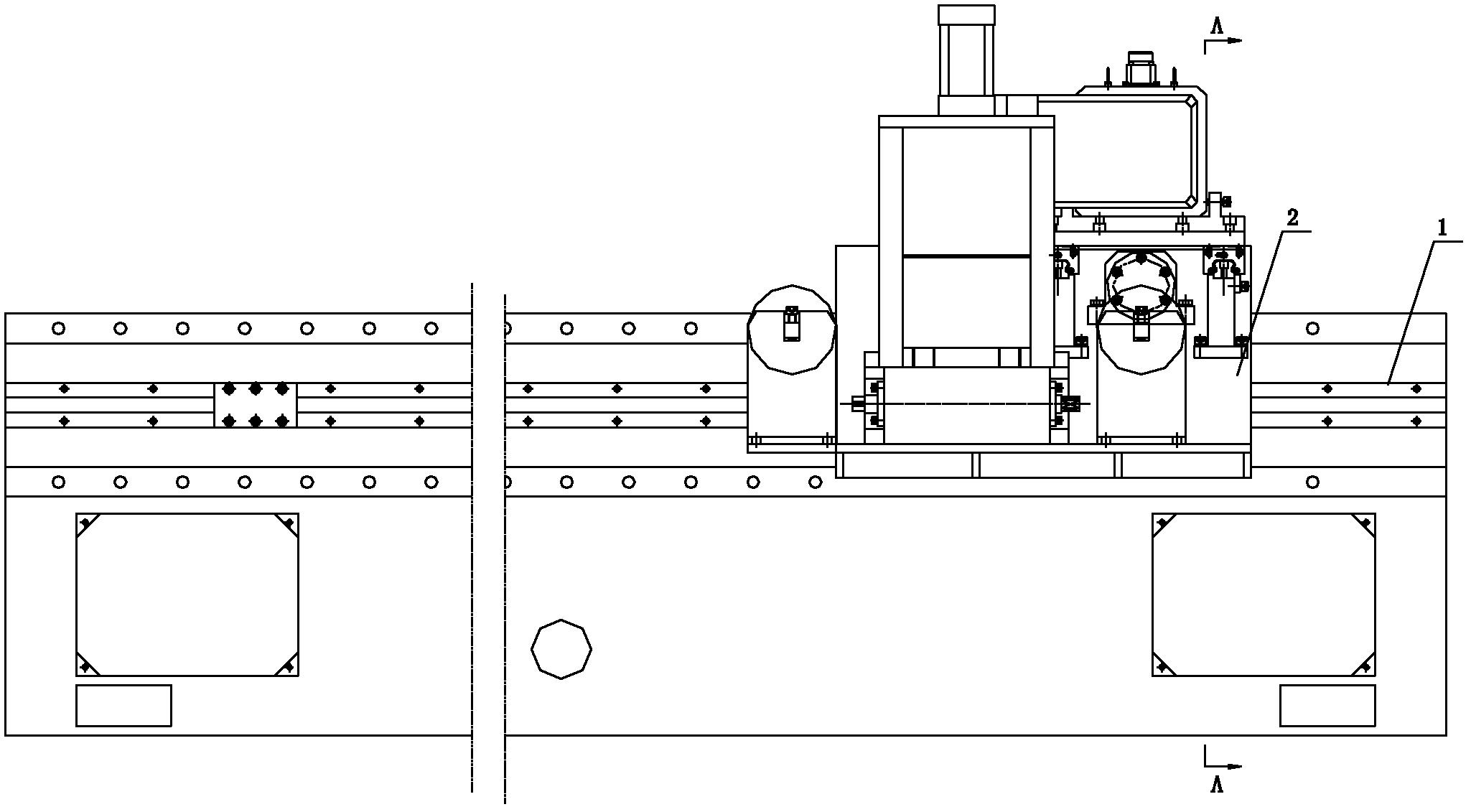

[0037] Example 1 as Figure 3-6 As shown, a milling mechanism of a pipe cutting machine includes a base 2, a guide block 18 is arranged on the lower part of the base 2, and the base 2 is connected with a linear guide rail 17 provided on the pipe cutting machine frame 1 through the guide block 18. The base 2 is provided with a leading screw 3, the end of the leading screw 3 is provided with a first variable speed motor 4, a sliding seat 5 is movable on the leading screw 3, a slide plate 6 is arranged on the sliding seat 5, and a plurality of slide plates are arranged on the slide plate 6. The guide block 13, the guide block 13 cooperates with the two guide rails 12 arranged on the base 2. The slide plate 6 is provided with a second variable speed motor 7 and a deceleration device 8 connected to the second variable speed motor 7, the deceleration device 8 is a speed reducer, and the second variable speed motor 7 is directly connected with the speed reducer. A clamping disc 10 a...

Embodiment 2

[0043] Example 2 as Figure 7-9As shown, a milling mechanism of a pipe cutting machine includes a base 2, a guide block 18 is arranged on the lower part of the base 2, and the base 2 is connected with a linear guide rail 17 provided on the pipe cutting machine frame 1 through the guide block 18. The base 2 is provided with a leading screw 3, the end of the leading screw 3 is provided with a first variable speed motor 4, a sliding seat 5 is movable on the leading screw 3, a slide plate 6 is arranged on the sliding seat 5, and a plurality of slide plates are arranged on the slide plate 6. A guide block (not shown in the figure), the guide block cooperates with the two guide rails 12 arranged on the base 2 . The slide plate 6 is provided with a second variable speed motor 7 and a reduction gear 8 connected with the second variable speed motor 7, the reduction gear 8 is a gear reduction box, and the second variable speed motor 7 is connected with the gear reduction box by a pair o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com