Plate-type ballastless track concrete track plate, manufacturing method thereof, and stretching device thereof

A slab-type ballastless track and concrete technology, which is applied to the manufacturing method, tensioning device, and ballastless track slab field, can solve the problems of easily forming capillary pores in concrete, exposing prestressed steel bars of track slabs, affecting the service life of track slabs, etc. The effect of increasing thickness, increasing service life and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

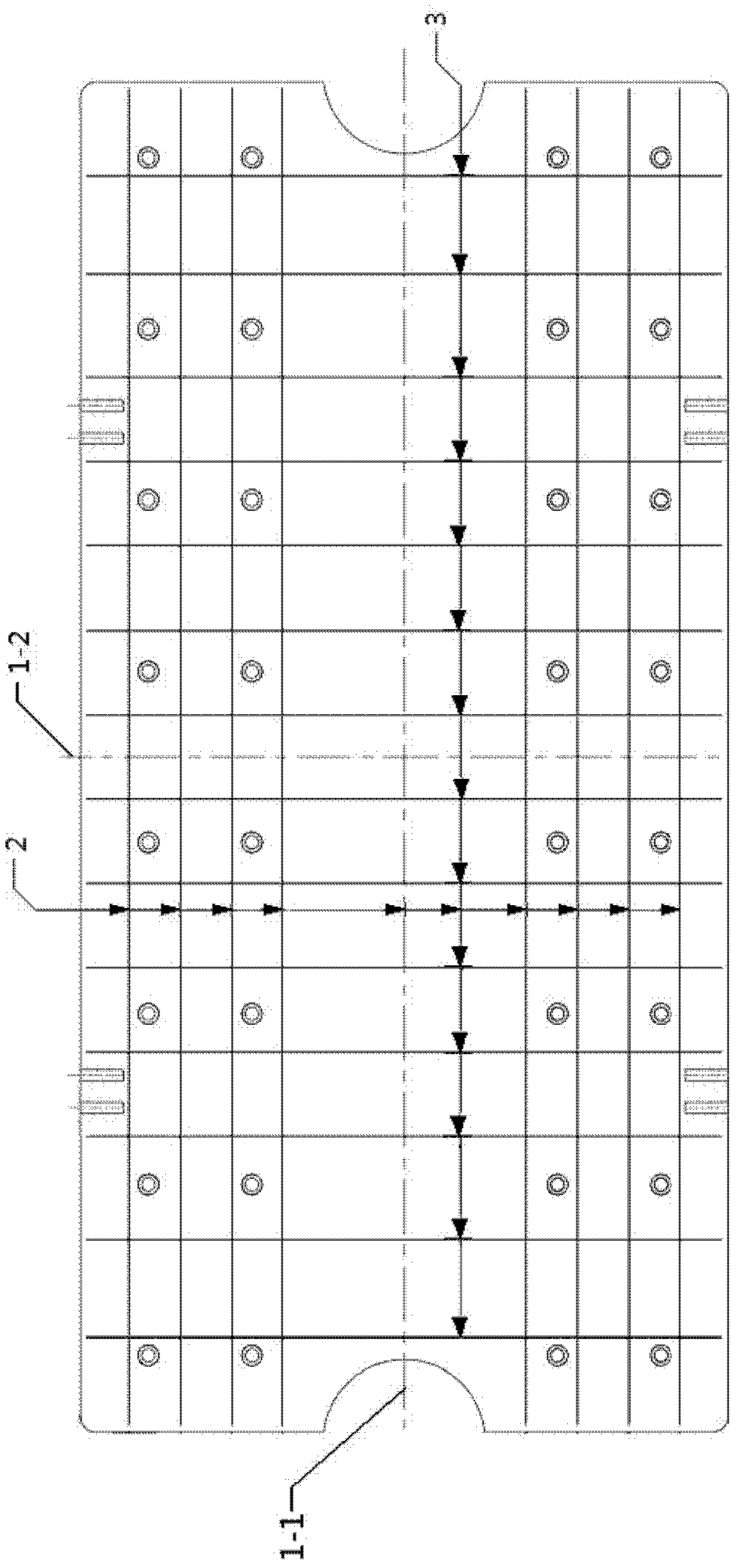

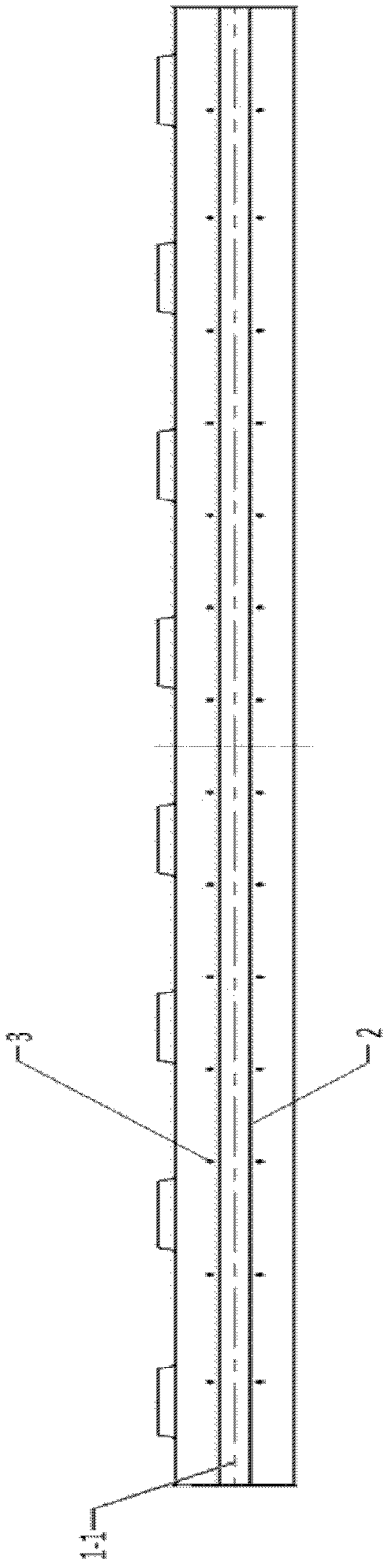

[0097] Such as figure 1 with figure 2 As shown, the concrete track slab of the slab ballastless track in this embodiment includes a slab body 1, in which a number of pre-tensioned longitudinal prestressed steel bars 2 are arranged. , And parallel to the longitudinal centerline 1-1 of the slab body, the prestressed steel bar is different from ordinary prestressed steel bars. The longitudinal prestressed steel bar is first tensioned. The prestressed steel bar 2 is prestressed before the concrete is poured in the slab 1, and the longitudinal direction is first stretched. The prestressed steel bar 2 is tightly combined with the concrete in the slab body 1. Since the concrete of the slab body 1 is poured before the longitudinal prestressed steel bar 2 is first tensioned, the shrinkage trend of the longitudinal prestressed steel bar 2 after the first tensioning can be It is more fully and densely combined with concrete to have greater binding power. After the concrete of the slab b...

Embodiment 2

[0099] Such as figure 1 with figure 2 As shown, the concrete track slab of the slab-type ballastless track in this embodiment is provided with a plurality of pre-tensioned longitudinal prestressed steel bars 2 in the slab body 1, and a number of pre-tensioned transverse prestressed steel bars 3 are also provided in the slab body 1.

[0100] The pre-tensioned transverse prestressed steel bar 3 refers to the pre-stressed steel bar that extends along the width direction of the slab body 1 and is parallel to the transverse centerline 1-2 of the slab body. The pre-tensioned transverse prestressed steel bar 3 is also the concrete in the slab body 1. The pre-stressed tension is completed before pouring, and the transverse pre-stressed steel bar 3 is tightly combined with the concrete in the slab body 1 first.

[0101] Similar to the anchoring effect of the first tensioned longitudinal prestressed steel bar 2, since the concrete of the slab body 1 is formed after the first tensioned trans...

Embodiment 3

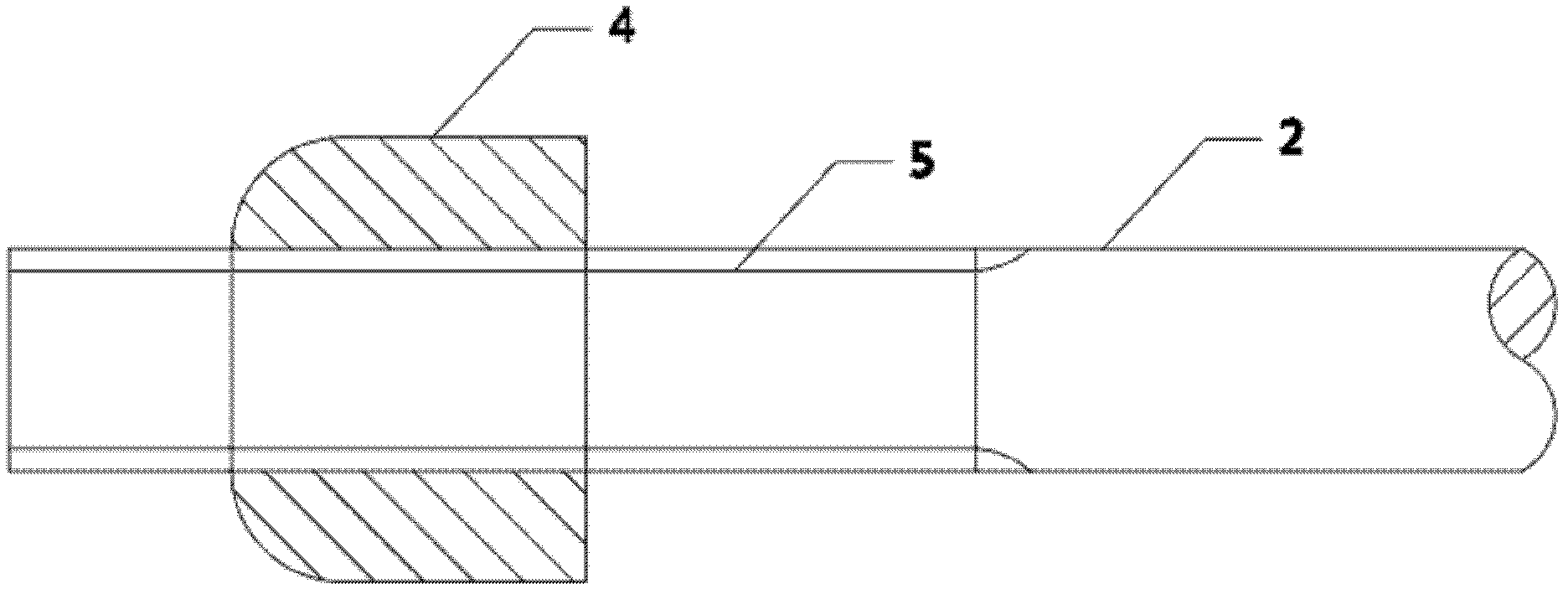

[0104] Such as Figure 3 to Figure 5 As shown, in the concrete track slab of the slab ballastless track of this embodiment, the pre-tensioned longitudinal pre-stressed steel bars 2 are anchored to the plate body 1 by the anchor plate 4, and the anchor plate 4 is in the shape of a cylinder. In the internally threaded hole 4a, the end of the first tensioned longitudinal prestressed steel bar 2 is provided with an external threaded section 5, and the first tensioned longitudinal prestressed steel bar 2 is threadedly connected with the anchor plate 4, and the anchor plate 4 interferes with the end surface of the plate body 1. The anchor plate 4 is connected to the end face of the plate body 1 in a snap-fit manner under the action of the prestress resilience force of the pretensioned longitudinal prestressed steel bar 2.

[0105] It should be noted that in the other embodiments, the first-tensioned longitudinal prestressed steel bar 2 and the anchor plate 4 can also be fastened by me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Radius | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com