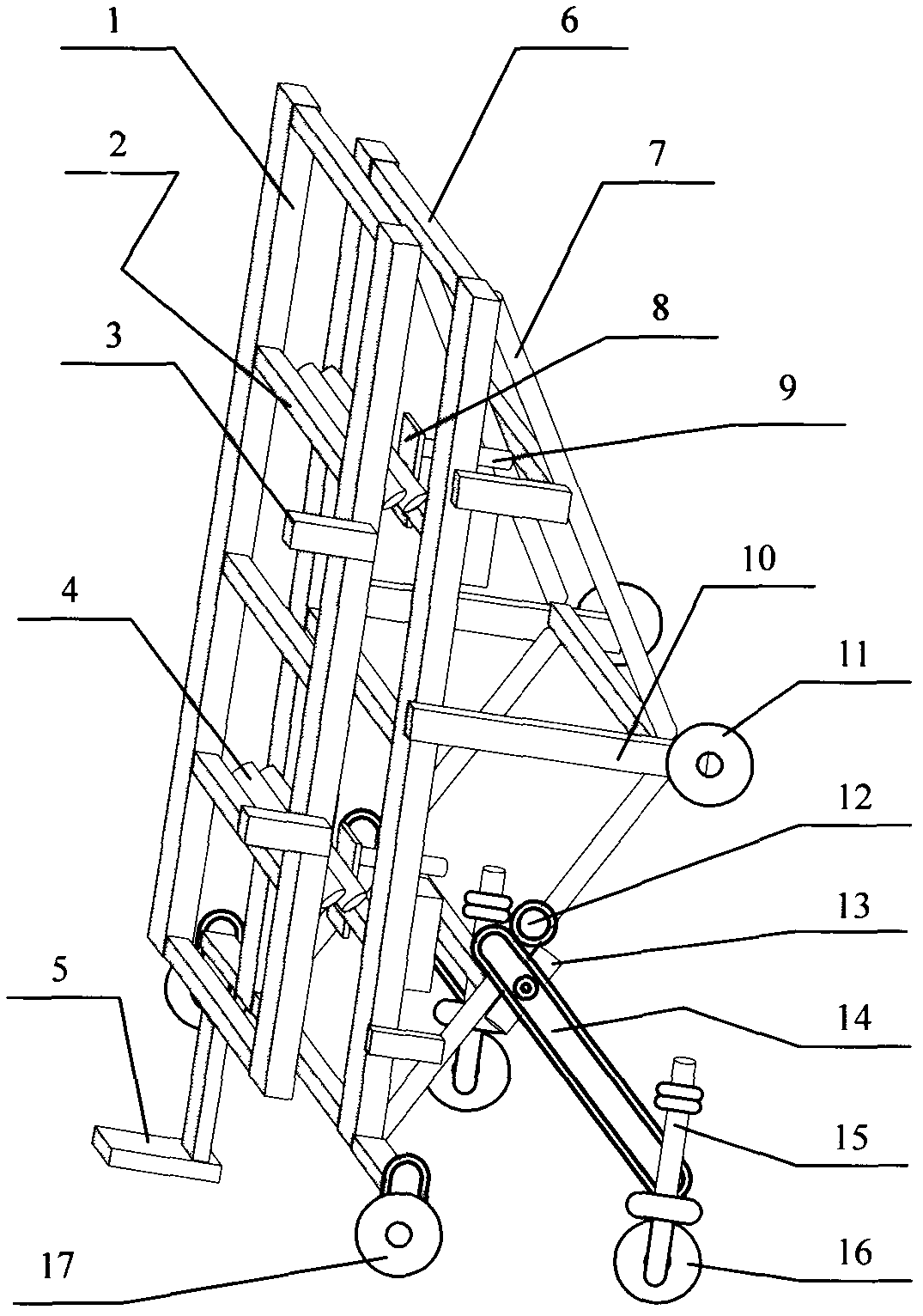

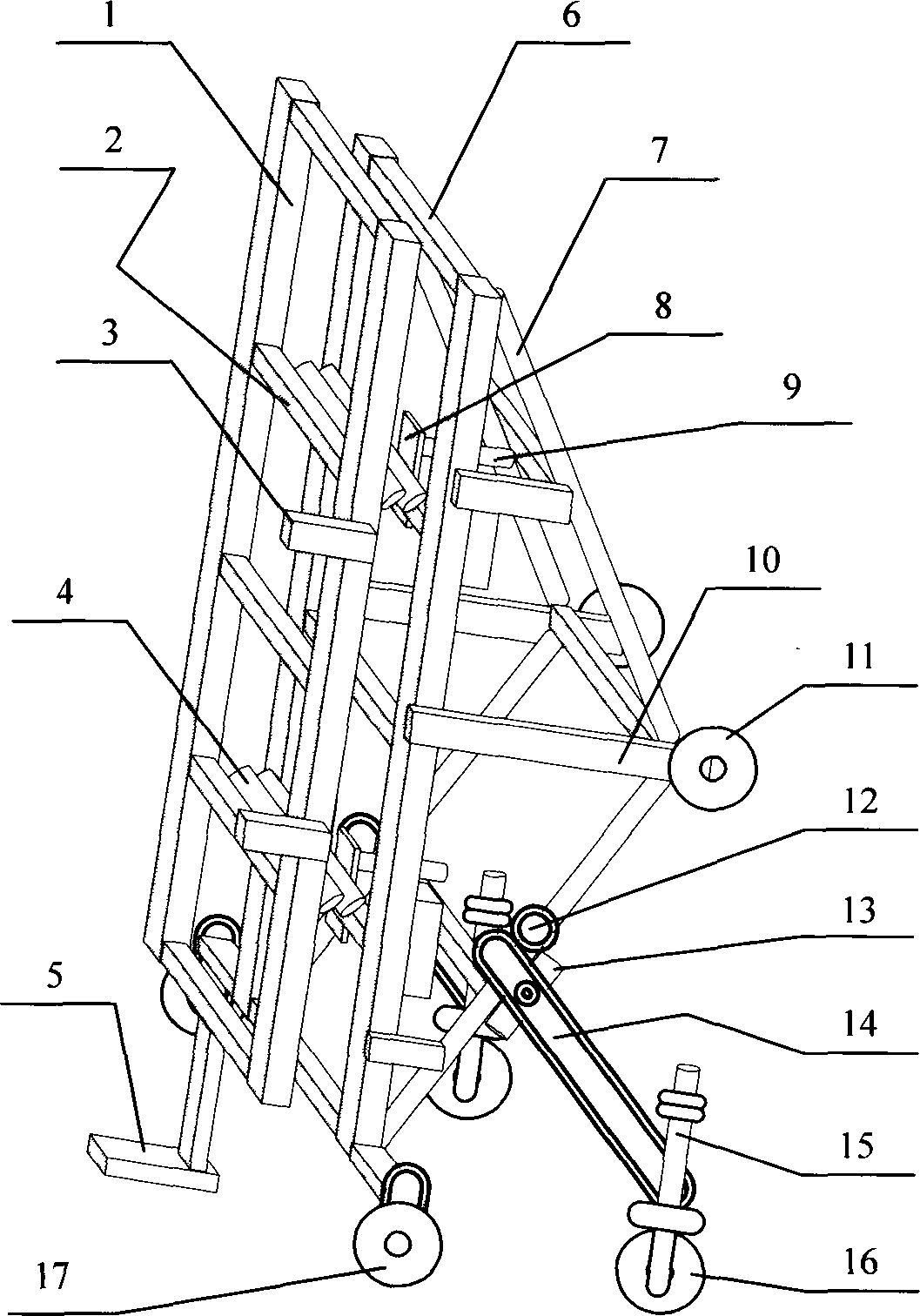

Movable wallboard-mounting carriage

A mobile, wall panel technology, applied in the direction of construction, building structure, building materials processing, etc., can solve the problems of difficult indoor transportation, high installation costs, high labor intensity, etc., to achieve simple and easy assembly and maintenance, and convenient operation , the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Further description will be given below in conjunction with the accompanying drawings and embodiments.

[0010] The rear side of the main frame 6 is installed with side wheels 11 through the support arm 10, the frame wheel 17 is installed at the lower end of the main frame 6, the front side of the main frame 6 is installed with the plate frame 1 through the hitch frame 4, the bottom of the plate frame 1 is connected with the bottom bracket arm 5, and the main frame 6. The plate frame 1 is installed by the hitch frame 4, and the live support leg 14 is hinged at the lower part of the rear side of the main frame 6, and the support wheel 16 is installed at the front end of the live support leg 14.

[0011] The plate frame 1 and the main frame 6 are rectangular frames, which are respectively composed of a pair of long frames on both sides and frame supports 2 connected between the frames.

[0012] A side stop 3 is installed on the side frame of the plate frame 1 . When the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap