Vibration reduction device of rotating elements

A vibration damping device and technology of rotating parts, applied in the field of vibration damping devices, can solve the problems of high cost, matching, and long manufacturing cycle, and achieve the effects of saving processing costs, realizing vibration damping effect, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

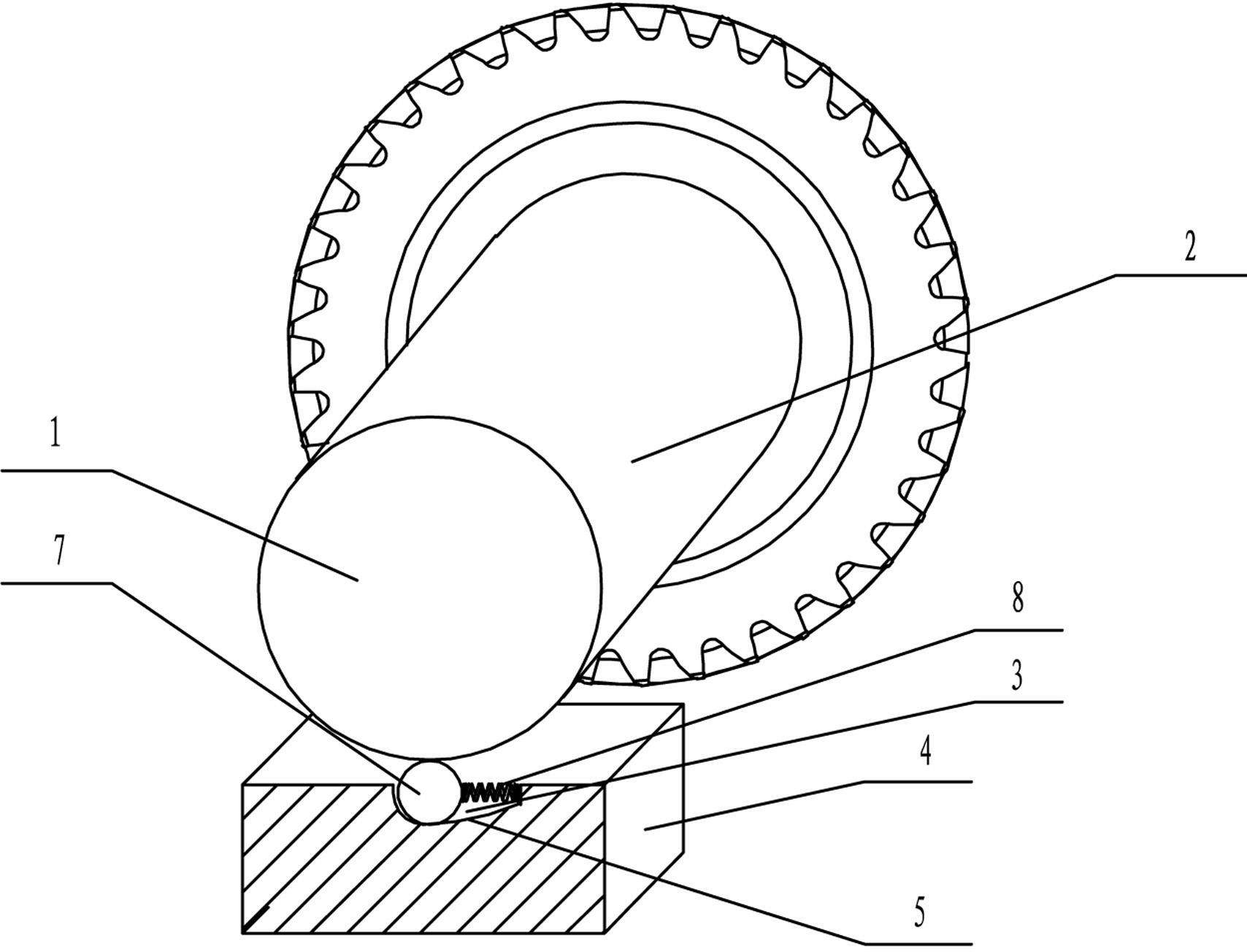

[0021] The vibration damping device for the rotating part of the present embodiment takes the gear as the rotating part 1 as an example. figure 1 As shown, the outer surface 2 is an end surface of the gear. The vibration damping device for rotating parts includes a housing 4 with a recessed part 3, and an embedded sleeve 9 is fixed in the recessed part 3 of the housing 4. The embedded sleeve 9 is a hollow cylindrical structure, and is embedded and fixed in the embedded sleeve 9. There is a guide part 6 with a guide surface 5. In this embodiment, the longitudinal section shape of the guide part 6 is a right-angled trapezoid. The inclined surface on the left side of the guide part is the guide surface 5. A rolling Body 7, rolling body 7 adopts ball, and the bottom of ball is provided with a spring 8 that is supported to ball, is fixedly connected with mosaic sleeve 9 inwalls, applies a supporting force to ball by spring 8, makes ball be in free state.

[0022] In use, when the ...

Embodiment 2

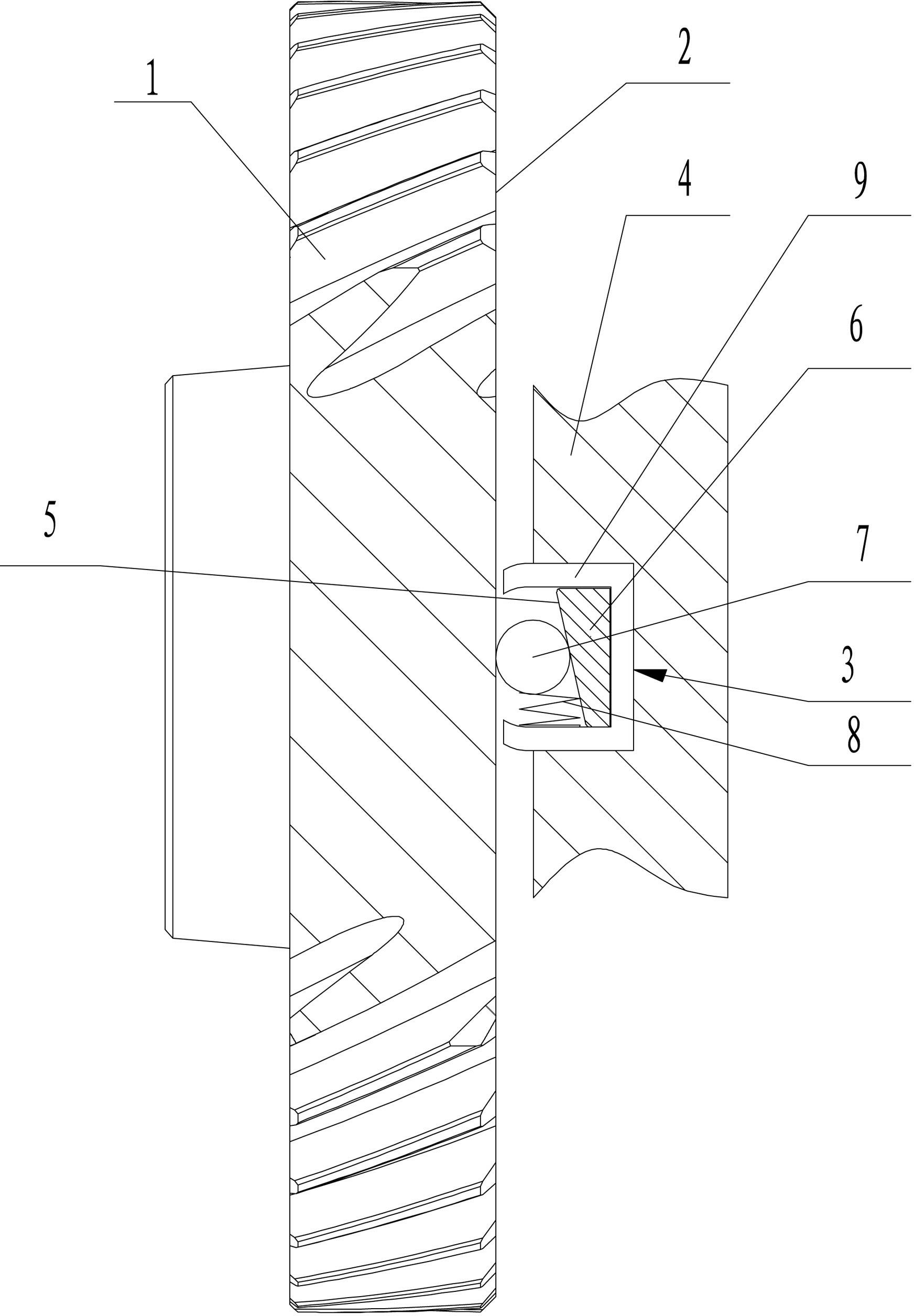

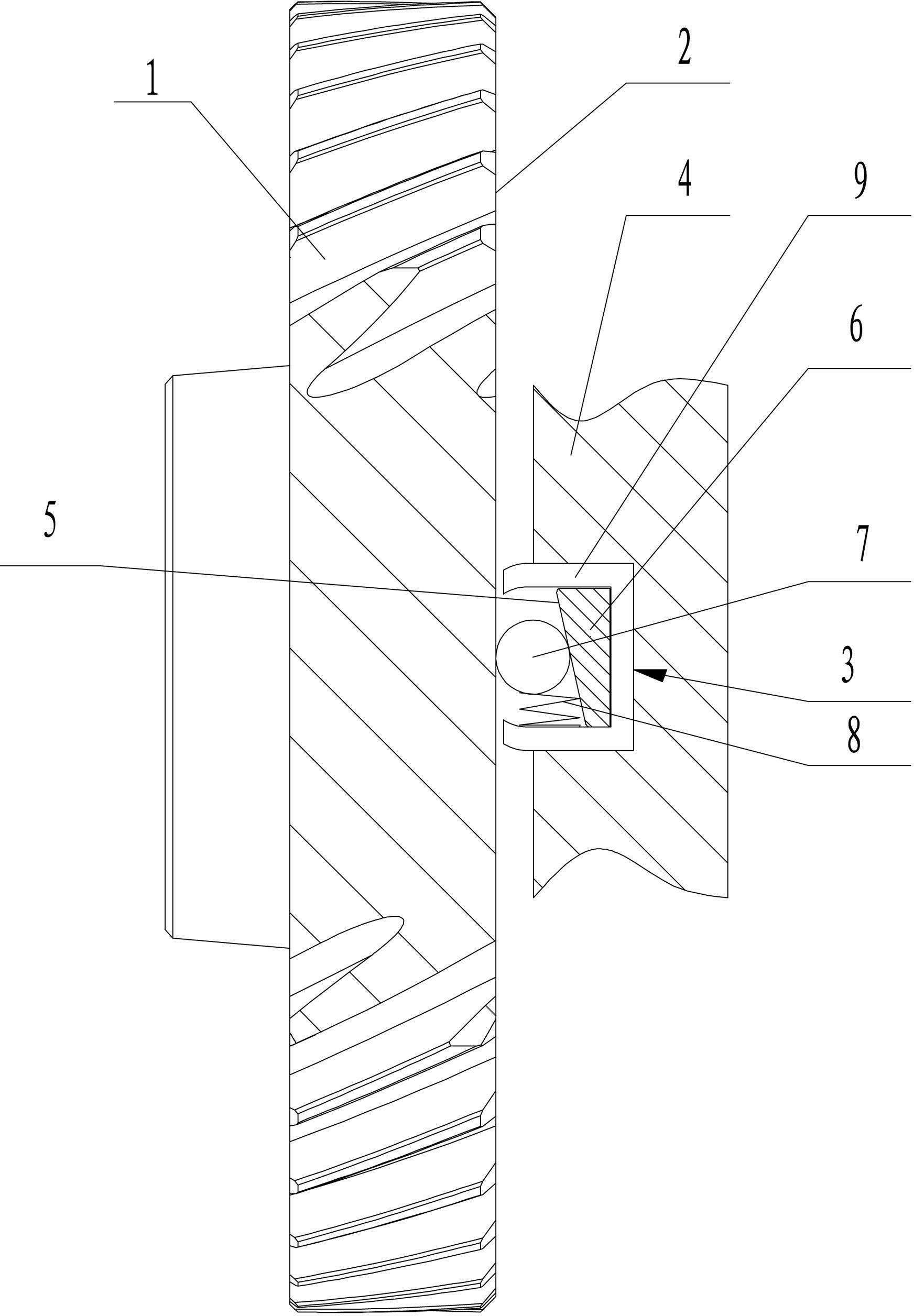

[0025] Depend on figure 2 It can be seen that the present embodiment takes the gear shaft as the rotating member 1 as an example. The vibration damping structure of the rotating member in this embodiment is basically the same as that of Embodiment 1, except that the inlay sleeve 9 is eliminated, and the recessed The bottom surface of the part 3 is used as the guide surface 5, and the guide surface 5 is designed as a curved surface, which makes the concave part 3 have a spatial structure that gradually becomes smaller from left to right. Depend on figure 2 It can be seen that when the gear shaft rotates clockwise normally, the gear shaft 1 drives the rolling body 7 to move to the left to a stable point, and the rolling body 7 above the stable point abuts against the gear shaft, and the rolling body 7 The bottom is in contact with the guide surface 5, and this contact point is the first position of the guide surface 5. When the gear shaft rotates abnormally, the rolling eleme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com