Armor optical fiber sensor suitable for road structure full size monitoring

A fiber optic sensor and road structure technology, applied in measuring devices, instruments, optical devices, etc., can solve the problems of limited test range and range, easy to be damaged, etc., to achieve long-term stable deformation, good test range, and improve survival rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific implementation manners of the present invention will be described in detail below in conjunction with the technical solutions (and accompanying drawings).

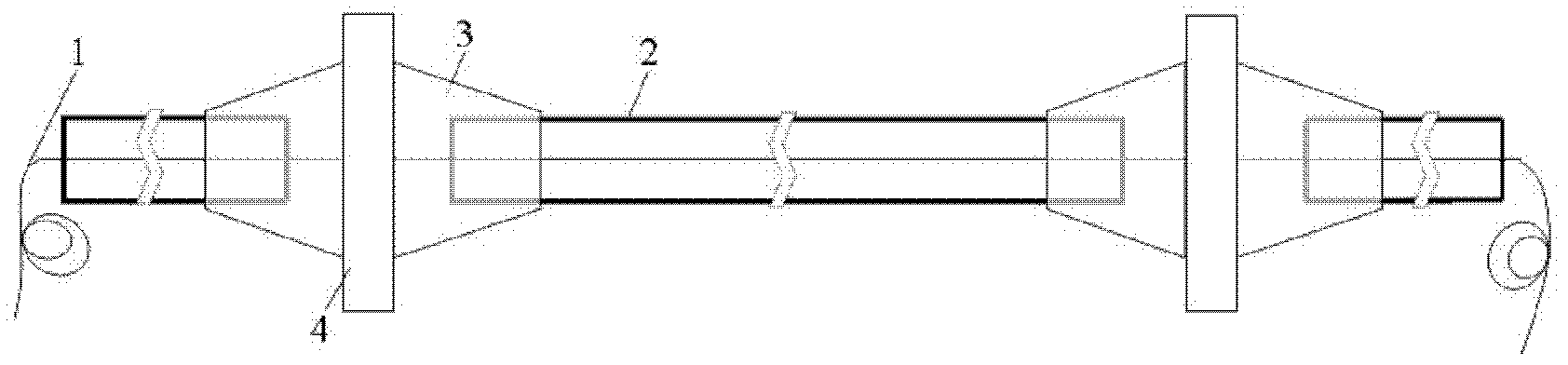

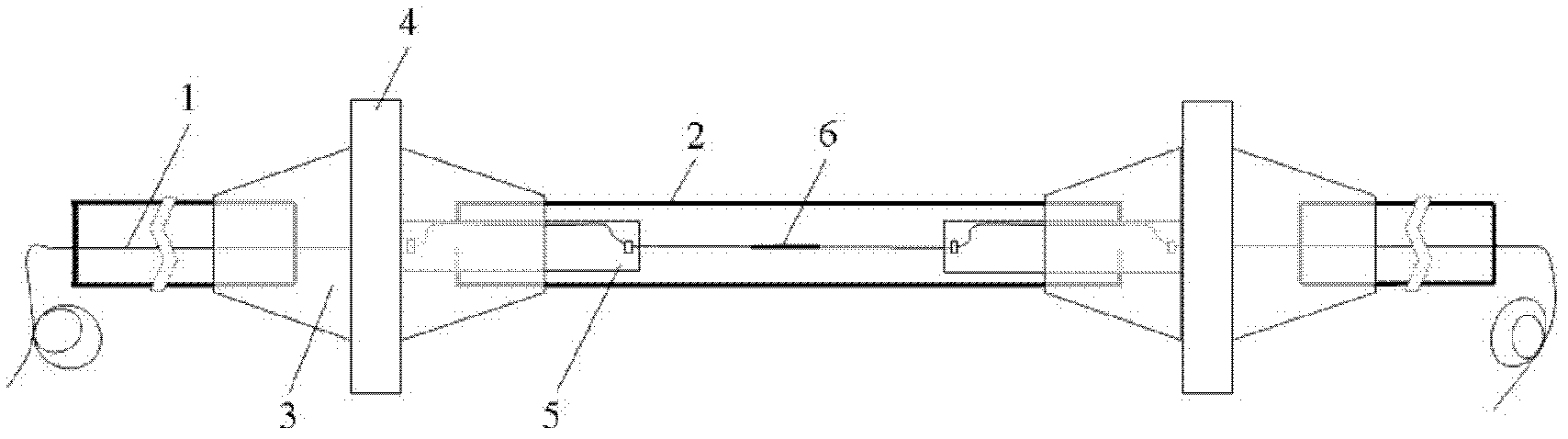

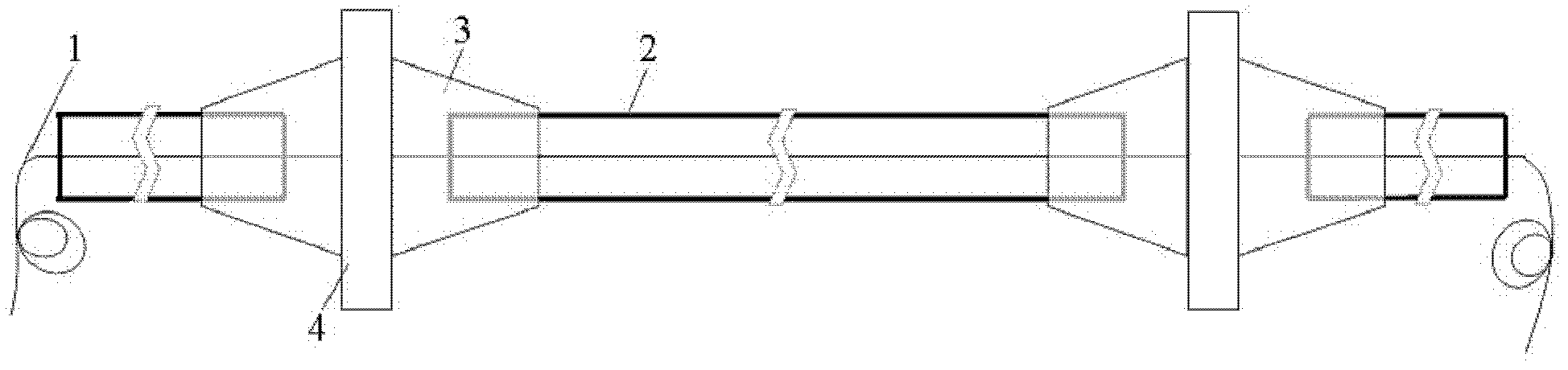

[0018] A system for large-scale and local large-strain monitoring of road structures using optical fiber sensing technology, as shown in the attached figure 1 and figure 2 As shown, it mainly includes: 1 distributed optical fiber (sensing optical fiber and transmission optical fiber); 2 armored wire; 3 rubber; 4 clamping block; 5 micro spring; 6FBG. Among them, the structure of the fiber optic sensor for the full-scale test of the road structure is shown in the attached figure 1 As shown, the fiber optic sensor for local testing of road structures is shown in the attached figure 2 shown.

[0019] The armored optical fiber sensing technology for full-scale monitoring of road structures, including large-scale and local testing technologies, is implemented as follows:

[0020] For local high-precisio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com