Simulation fatigue testing device for suspension motor suspension hanging plate spring of motor

A fatigue test and suspension motor technology, which is applied in the direction of applying repetitive force/pulse force to test the strength of materials, and can solve problems such as lack of mature technical specifications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with accompanying drawing.

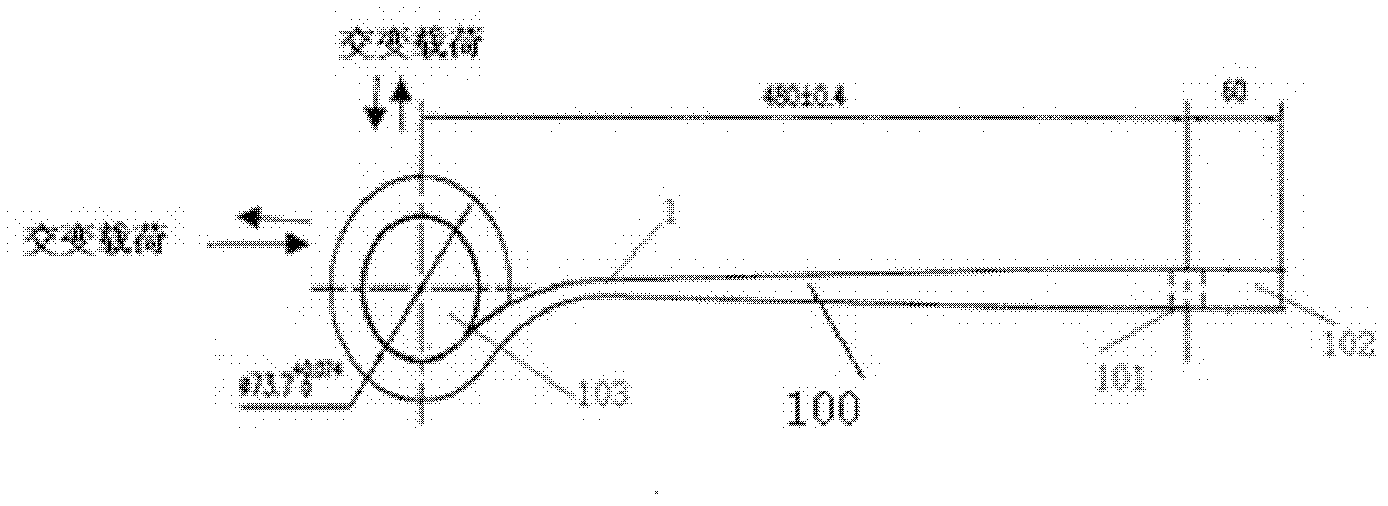

[0015] Such as figure 1 Shown is the spring structure of the motor optional suspension plate. Flat plate end 102 with hole 101 and ear hole end 103 . During the test, fix the flat end of the motor suspension leaf spring on the figure 2 On the plate end clamping table 20 shown, the width of the plate end is 80 mm, and the thickness is 20 mm.

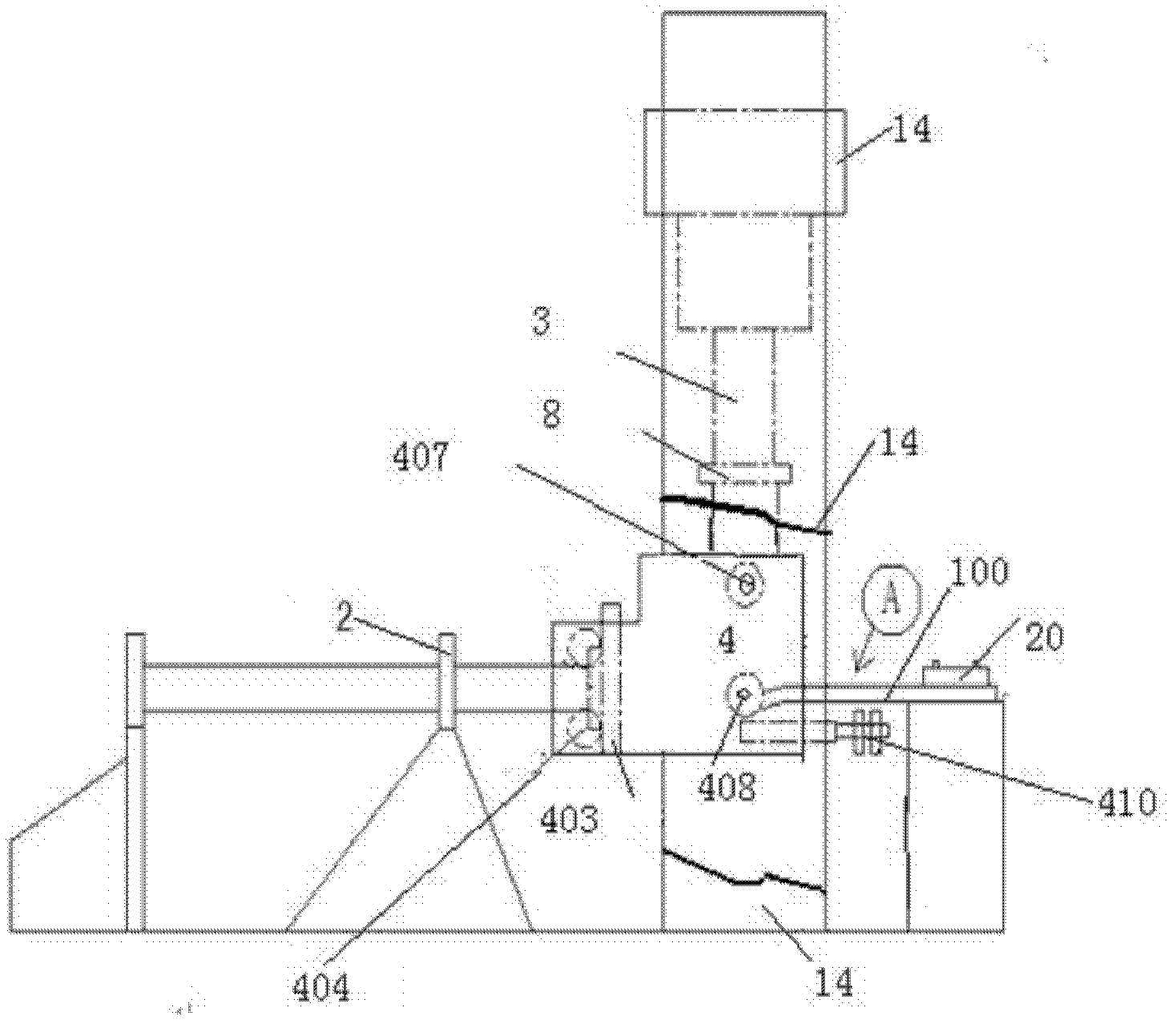

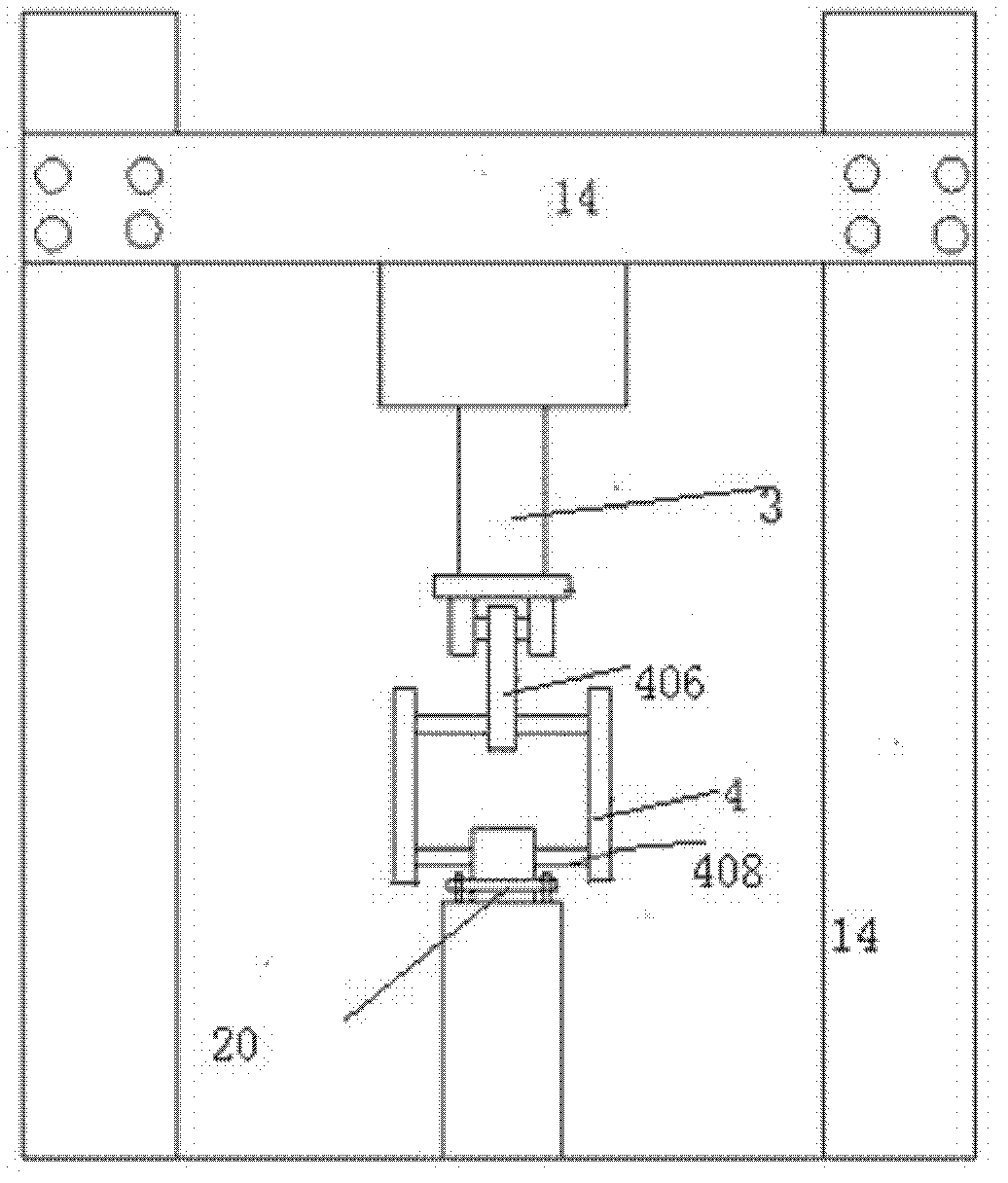

[0016] In order to simulate the actual situation during the operation of the locomotive, the leaf spring 100 is fixed in a cantilever beam state. While bearing alternating axial loads, it also bears lateral displacements that change according to the law of symmetry cycles, resulting in bending deformation. Under working conditions, it must be ensured that the leaf spring will not be damaged by fatigue within the expected life. figure 2 and image 3 The axial load shown in is the vertical direction when the train is actually run...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com