Wrist threading barrel for multi-degree-of-freedom flexible robot for single-incision laparoscopic minimally invasive surgery

A minimally invasive surgery, threading barrel technology, applied in the field of surgical robots, can solve the problems of difficult design of the robot end structure, low integration, complex structure, etc., and achieve the effect of reducing the overall size, ensuring smooth movement, and reducing complexity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

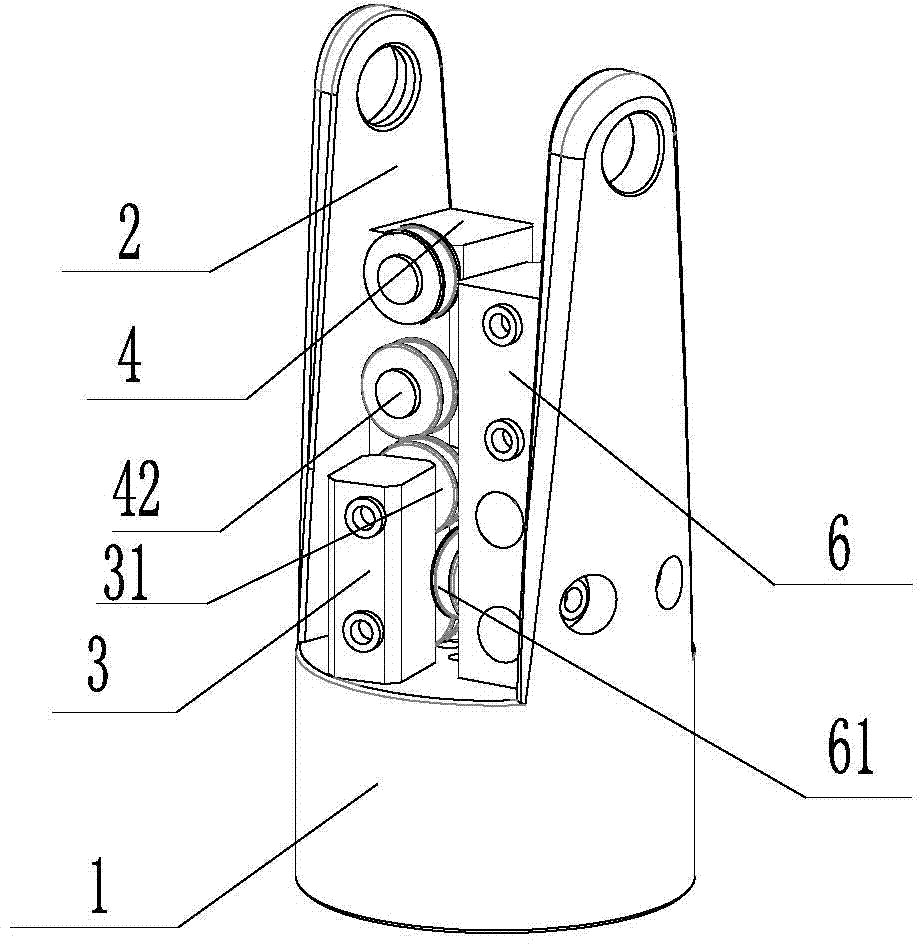

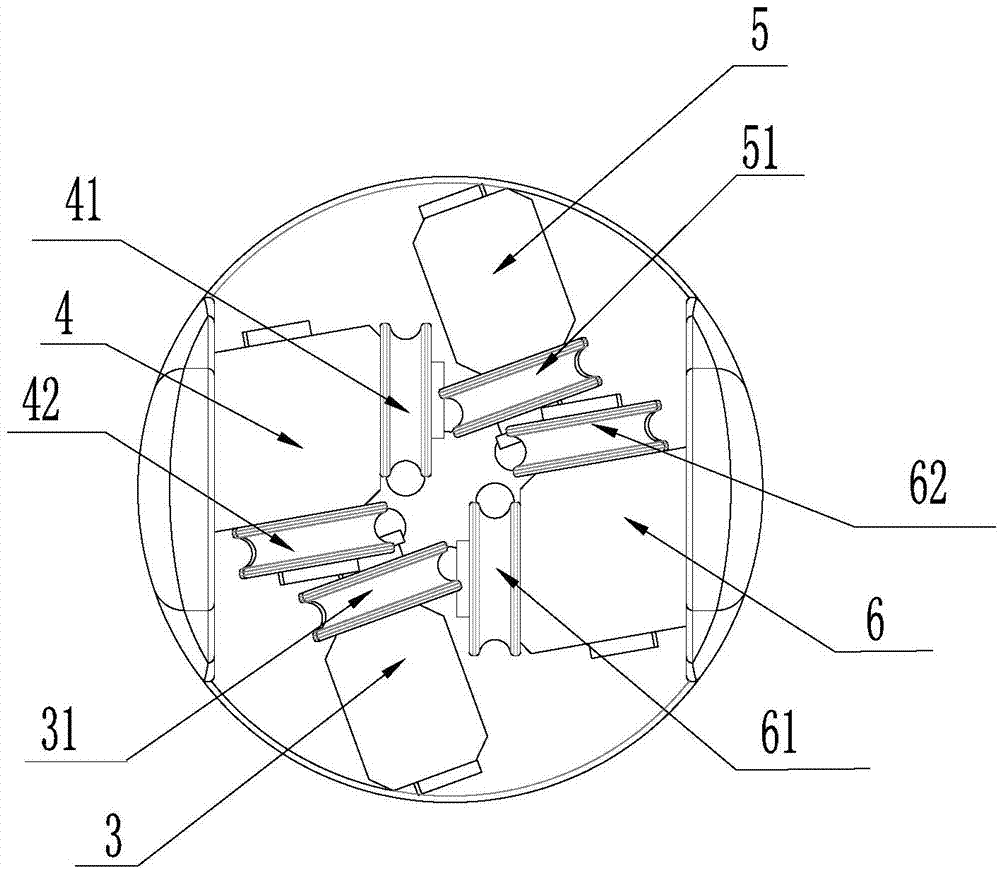

[0007] Specific implementation mode one: combine figure 1 and figure 2 Describe this embodiment. The wrist threading barrel of this embodiment is made of a base 1 and two connecting ears 2. The base 1 is provided with a first guide wheel fixing column 3, a second guide wheel fixing column 4, and a third guide wheel. The wheel fixed post 5 and the fourth guide wheel fixed post 6, the first guide wheel fixed post 3 and the third guide wheel fixed post 5 are distributed symmetrically with respect to the center of the wrist threading bucket base 1, the second guide wheel fixed post 4 and the third guide wheel fixed post 5 The four guide wheel fixing posts 6 are distributed symmetrically with respect to the center of the wrist threading bucket base 2, and the inner wall of the first guide wheel fixing post 3 is provided with two first guide wheels 31, and the two first guide wheels 31 are arranged along the first The height direction of the guide wheel fixed column 3 is aligned a...

specific Embodiment approach 2

[0008] Specific implementation mode two: combination figure 1 Illustrate, the height of the first guide wheel fixed column 3 of present embodiment is 5mm, the height of the second guide wheel fixed column 4 is 10mm, the height of the 3rd guide wheel fixed column 5 is 5mm, the 4th guide wheel fixed column 6 The height is 10mm. The diameter of the first guide wheel, the second guide wheel, the third guide wheel, the fourth guide wheel, the fifth guide wheel and the sixth guide wheel is 2.4mm, the first guide wheel, the second guide wheel, the third guide wheel, The inner wheel grooves of the fourth guide wheel, the fifth guide wheel and the sixth guide wheel are distributed in the circumference of the base diameter of 3mm, through the first guide wheel, the second guide wheel, the third guide wheel, the fourth guide wheel, the The guiding effect of the fifth guide wheel and the sixth guide wheel can make the driving wire acting on the rear end of the end threading barrel expand...

specific Embodiment approach 4

[0009] Embodiment 4: The outer diameter of the base 1 in this embodiment is 10 mm, so that the dual-arm robot can enter the body through an incision that meets the requirements of human skin for surgery, and the robot as a whole is easy to disassemble and carry. Other implementation manners are the same as the specific implementation manner 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com