Combined wind wave and current resistant net cage and working method thereof

A combination of anti-wind and wave technology, applied in fish farming, animal husbandry, applications, etc., can solve the problems of difficult management, poor resistance to sea current deformation, and low wind and wave resistance, so as to improve the performance of anti-current deformation and improve Anti-typhoon ability and the effect of improving the modernization level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

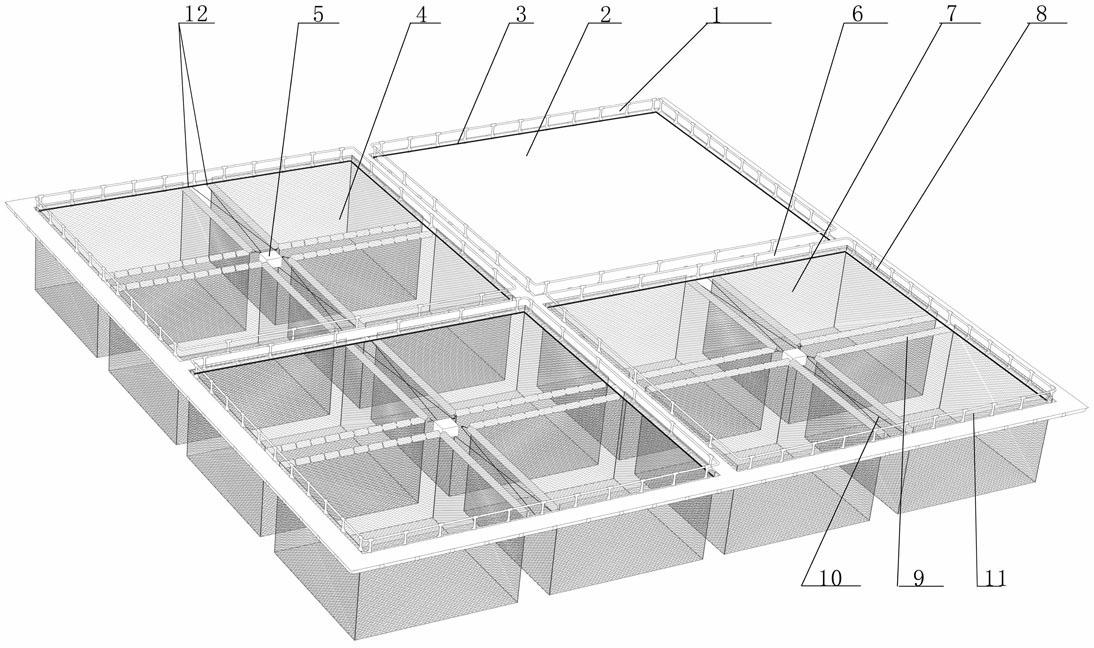

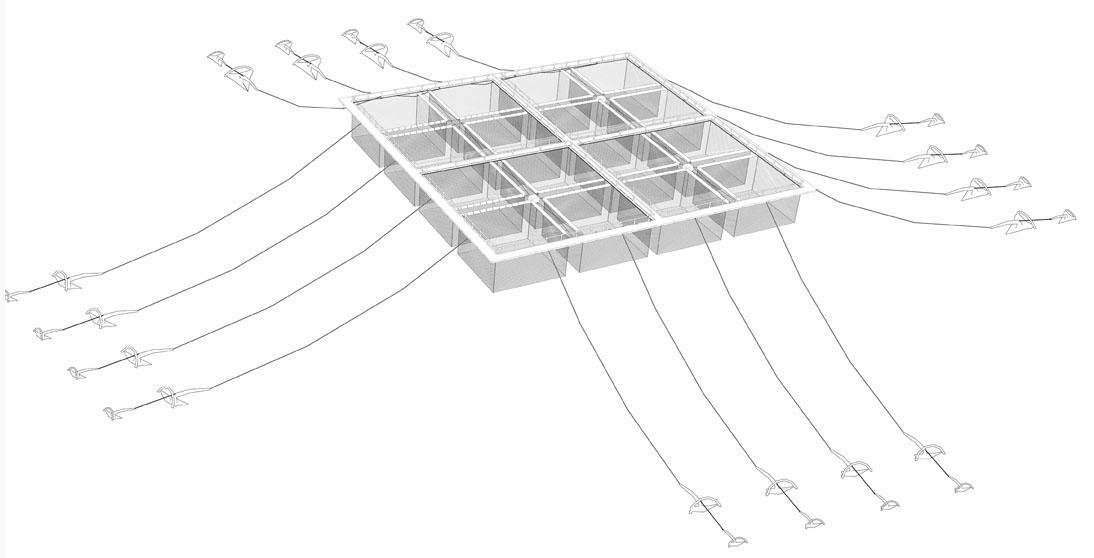

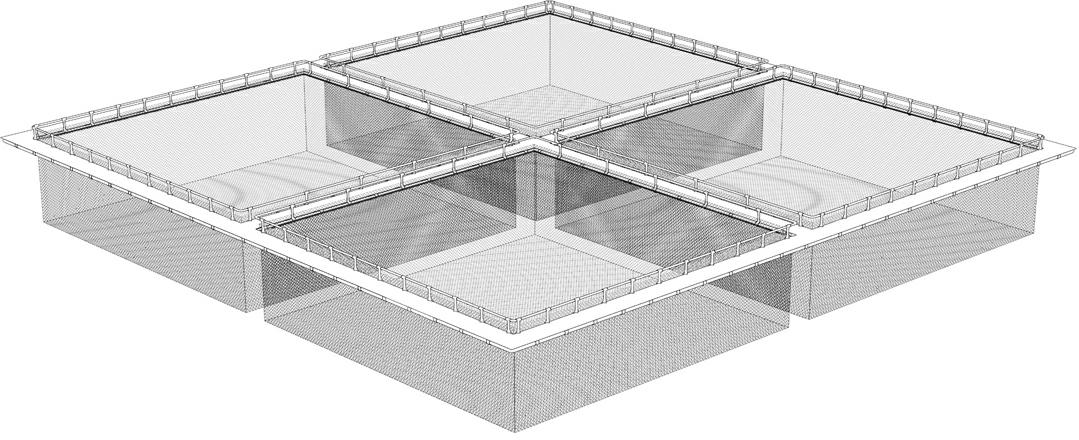

[0021] A kind of combined anti-wind and wave current net cage and its working method described in the present invention, such as figure 1 , 2 , 3, 4

[0022] figure 1 A schematic diagram of the unit cage. A one-piece frame 1 made of HDPE pipes is provided with several square cage units 2; under each side of the HDPE one-piece frame, a floating rope frame 3 made of high-strength fiber ropes is arranged on the side close to the square cage units ; A number of net clothes boxes 4 can be arranged in every floating rope frame; adjacent net clothes boxes 4 in the same square net cage unit are fixed by multi-net cage connectors 5 .

[0023] figure 2 It is a standard combined net cage with 4 × 4 net cages inside, that is, a 16-mouth × 100㎡ net clothing box. Each square net cage unit is equipped with four net clothes boxes, and the distance between the net clothes of adjacent net cages is one meter; each net clothes box 4 has two adjacent sides tied on the HDPE frame, and its oth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com