Molding method of cold-bending steel plate pile provided with non-uniform-thickness lock buckle

A forming method and non-uniform thickness technology, which is applied in the direction of sheet pile walls, buildings, and foundation structure engineering, can solve problems such as unoptimized cross-sectional dimensions, easy tearing of pile bodies, and loose buckles at joints, so as to prevent Cracking phenomenon, reducing equipment requirements, and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

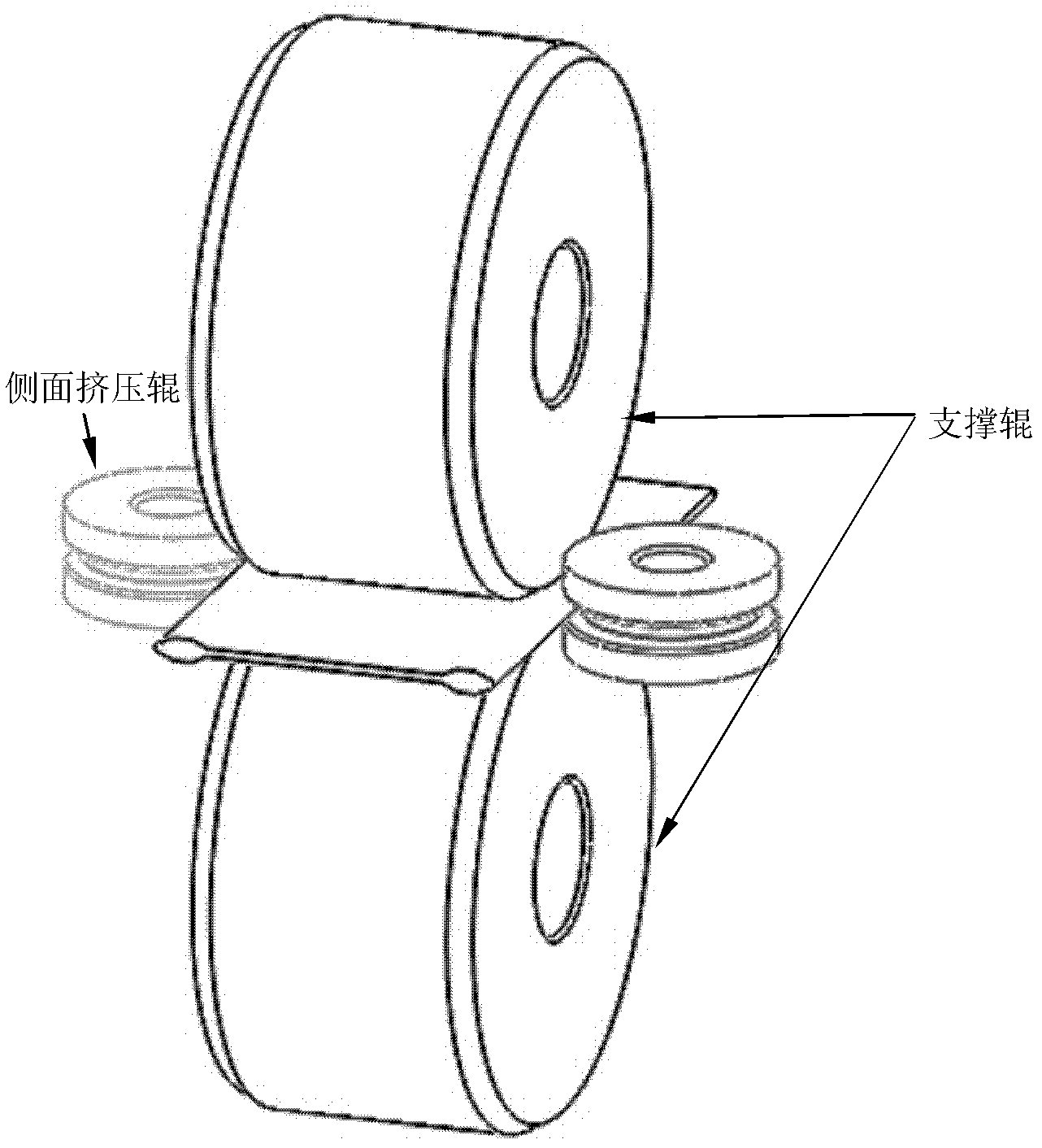

[0035] 1) Prepare a flat plate with a length of 2000mm, a width of 220mm, and a thickness of 5.5mm. The front end of the plate must have a certain slope; 2) The plate advances in the roll at a feed speed v (there is no special limit to the speed v ); 3) The sheet passes through the induction coil (if attached Figure 5 As shown), the induction coil heats the edge of the sheet to a temperature of 500°C with power P; 4) Extrusion of the sheet is carried out in four passes, and the feed rate of each pass is 8mm→5.5mm→ 4mm→2.5mm; 5) The transitional sheet passes through the forming roller to obtain a sheet with non-equal-thickness locks; 6) The sheet with non-equal-thickness locks is cold-bent into a sheet with non-equal-thickness locks through subsequent forming passes Locked steel sheet piles.

Embodiment approach 2

[0037] 1) Prepare a sheet with a length of 2000mm, a width of 220mm, and a thickness of 5.5mm. The front end of the sheet must have a certain slope; 2) The sheet advances in the roll at a feed speed v; 3) The sheet passes through the induction coil ( as attached Figure 5 As shown), the induction coil heats the edge of the sheet to a temperature of 900°C with a power P; 4) The sheet is extruded in six passes, and the feed rate of each pass is 5mm→4.5mm→ 4mm→3mm→2.5mm→1mm; 5) The transition sheet passes through the forming roller to obtain a sheet with non-equal-thickness locks; 6) The sheet with non-equal-thickness locks is cold-bent into a Sheet piles with unequal-thickness locking.

[0038] Compared with the prior art, the present invention has the beneficial effects of:

[0039] (1) In the present invention, the edge of the sheet is heated to a high temperature by means of induction heating, and the plasticity of the sheet is obviously improved. Compared with the traditi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com