Forging molding process for integral hollow nuclear power main pipe

A technology for forging forming and main pipes, which can be used in engine components, mechanical equipment, etc., and can solve problems such as difficulty in heating control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

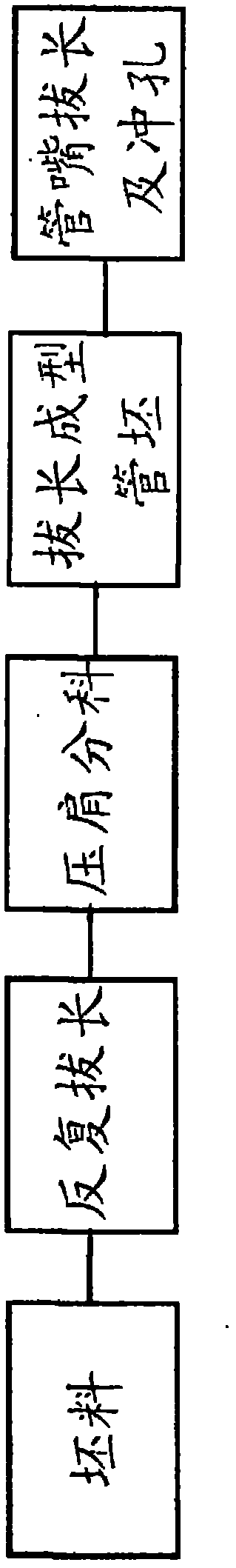

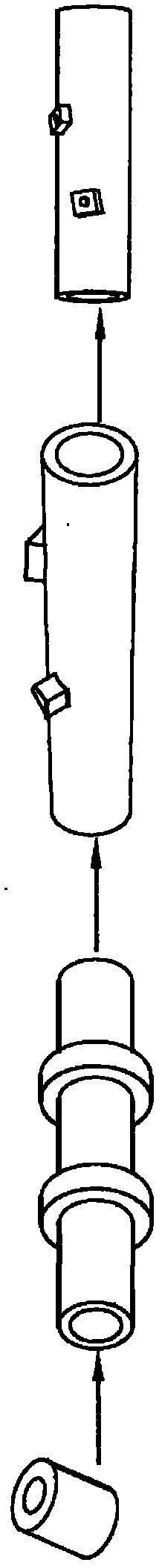

Method used

Image

Examples

specific Embodiment

[0030] Since the technology of AP1000 main pipes at home and abroad so far has been formed by solid forging of solid steel ingots, there is no technology for hollow forging of hollow steel ingots. The current third-generation nuclear power main pipeline cannot be widely applied in nuclear power projects due to its high cost. Due to the difficulty in controlling the performance of the AP1000 main pipeline, the waste of expensive raw materials is serious. Since 316LN stainless steel is an austenitic stainless steel without allotropic transformation, it is difficult to control the forging heating in order to prevent the grain size from growing.

[0031] And secondly after using the embodiment described in the present invention

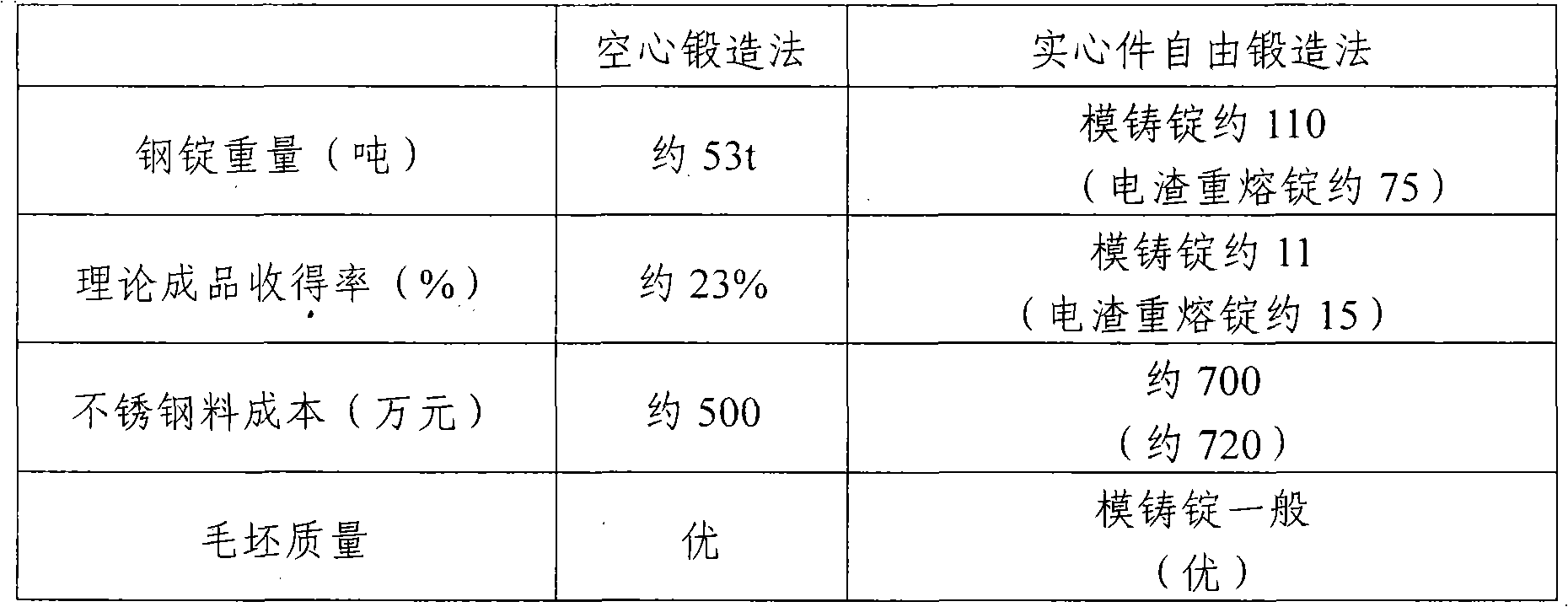

[0032] In terms of cost and raw material saving, compare the following table:

[0033]

[0034] Stainless steel heating:

[0035] The correct heating specification ensures the "three zeros" under the premise of basic uniform heating: zero "bubble fu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com