Mold opening and closing device and control method of electro-hydraulic hybrid injection molding machine

An electro-hydraulic hybrid injection molding machine technology, applied in the field of injection molding machines, can solve problems such as complex clamping structure, achieve the effect of short mold opening and closing cycle, precise and controllable clamping force, and eliminate the impact of the whole machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

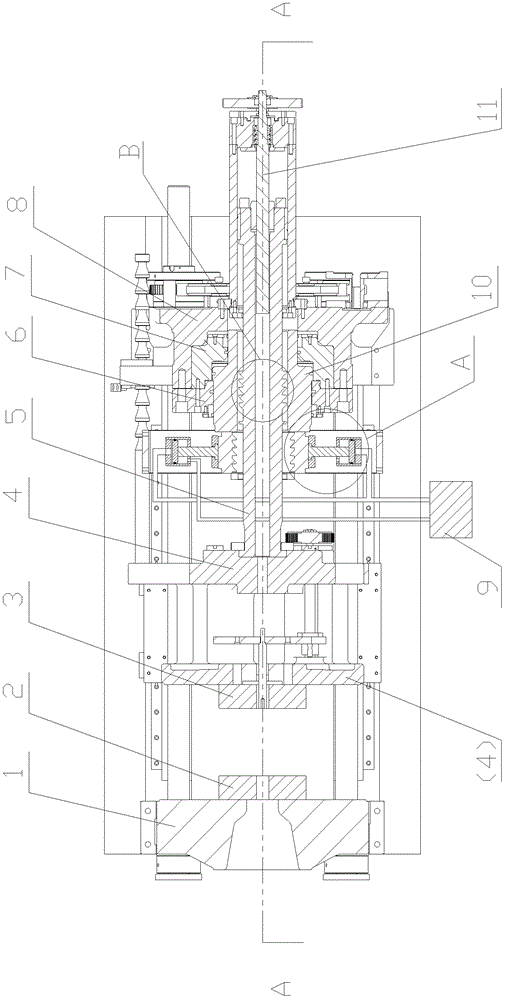

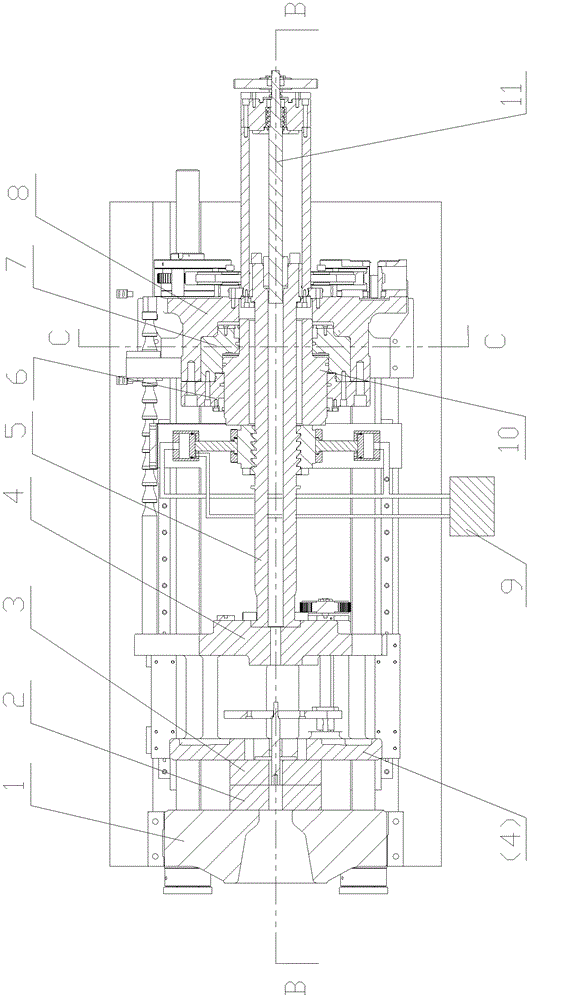

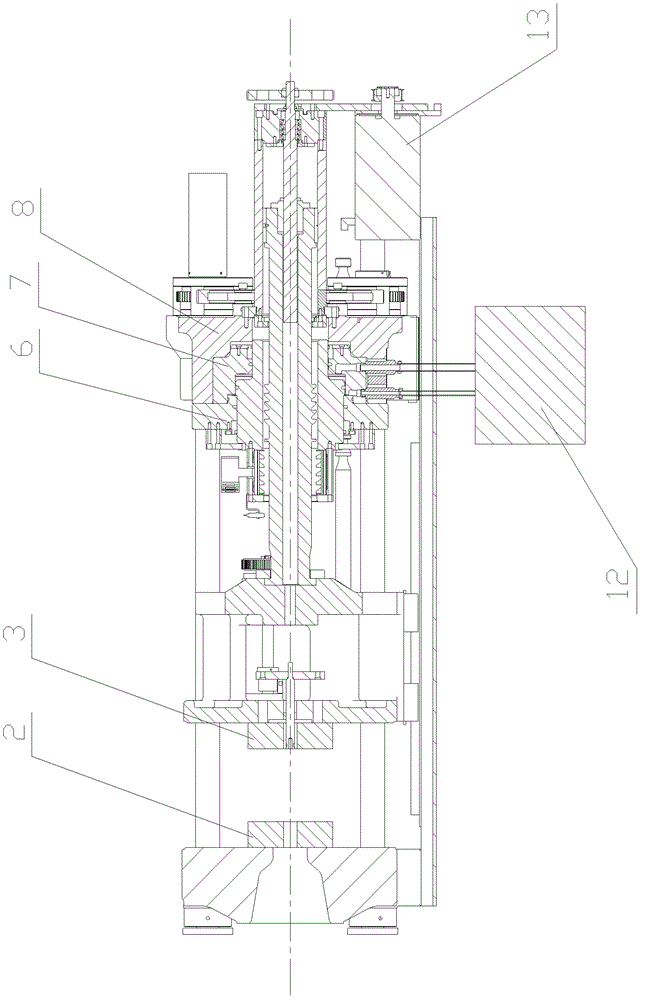

[0032] refer to Figure 1~8 As shown, a mold opening and closing device for an electro-hydraulic hybrid injection molding machine of the present invention includes a front template 1, a fixed mold 2, a movable mold 3, a rear template 8, a movable template 4, a servo motor 13, a high-pressure hydraulic oil generator 12, The ball screw 11 and the ball screw 11 drive the mold moving rod 5 that moves axially and linearly. The mold moving rod 5 is positioned in the rear template 2, the rear end is linked with the servo motor 13, and the front end is connected to the movable template 4. The rear template 8 is equipped with High-pressure oil cylinder 7, high-pressure piston rod 10, mold-closing high-pressure oil chamber 15 and mold-opening high-pressure oil chamber 16 are formed between the front and rear sides of high-pressure piston rod 10 and high-pressure oil cylinder 7, and the pipelines of high-pressure hydraulic oil generating device 12 are connected to mold-closing high pressu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com