Mobile vertical compression pit horizontal waste compression station

A garbage compression station, pit horizontal type technology, applied in the field of mobile vertical pressure pit horizontal garbage compression station, can solve the problems of high empty-load ratio of hook-arm truck trailer, insufficient compression density of horizontal compression, high equipment maintenance costs, etc., to achieve Good motion control effect, saving investment cost, and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

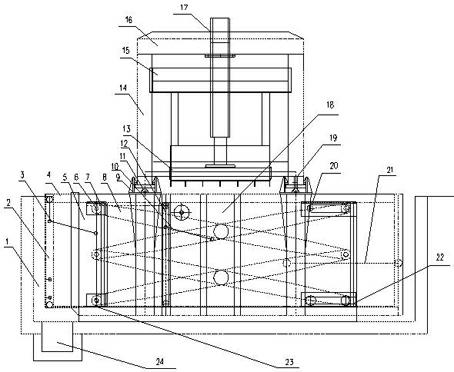

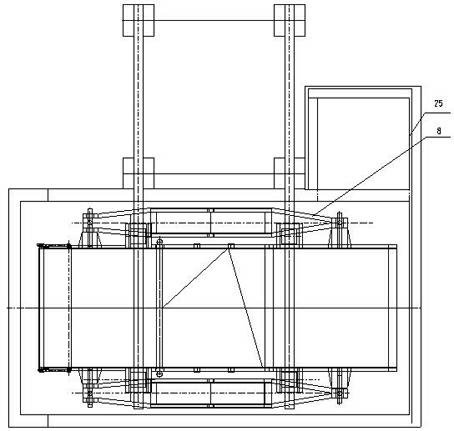

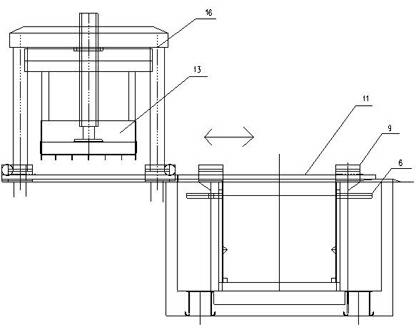

[0022] Such as Figure 1-7 As shown, the present invention is a mobile vertical pressure pit horizontal garbage compression station, which has a pit 1, a mobile press 14 is arranged on the top of the pit 1, and a compression box 4 and its lifting device are arranged in the pit 1. The top of the compression box 4 is provided with a material inlet, and the front is provided with a material outlet, and the moving press 14 is provided with a compression head 13 and its driving device, and the driving device drives the compression head 13 to reciprocate in the vertical direction.

[0023] The mobile press 14 is arranged on the ground. First, two sections of guide rails 11 are respectively arranged on the top of the compression box 4 and the ground. When the compression box 4 is in the pit 1, the two sections of guide rails 11 are connected, and the bottom of the mobile press 14 Matching roller 19 is set. At the same time, a rotary shaft and a driving device are arranged on one sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com