Collating machine

A collating machine and rack technology, applied in the directions of sending objects, thin material handling, transportation and packaging, can solve the problems of increasing labor intensity, reducing production efficiency, and high paper requirements, reducing labor intensity, improving production efficiency, The effect of stable paper feeding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

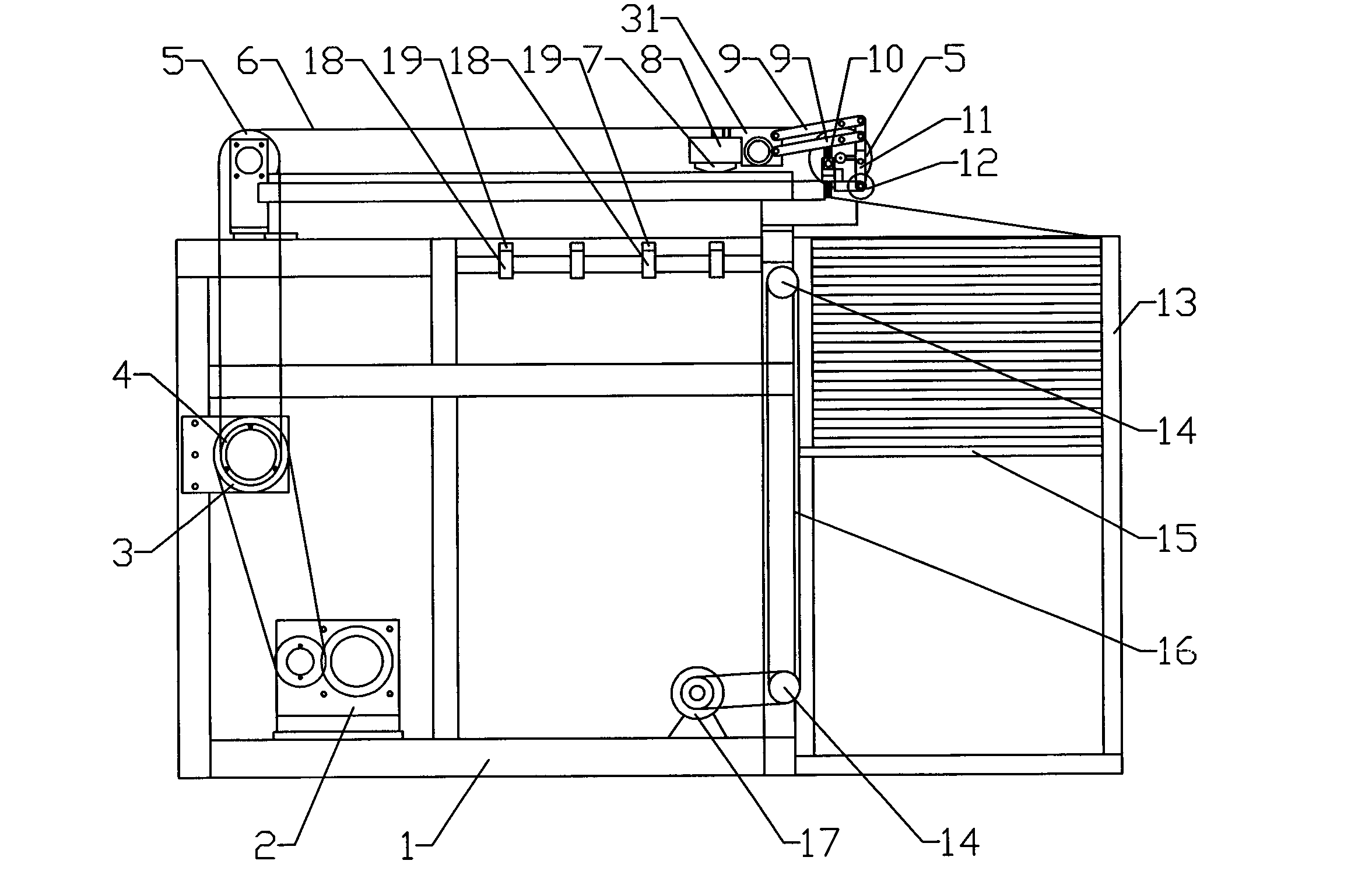

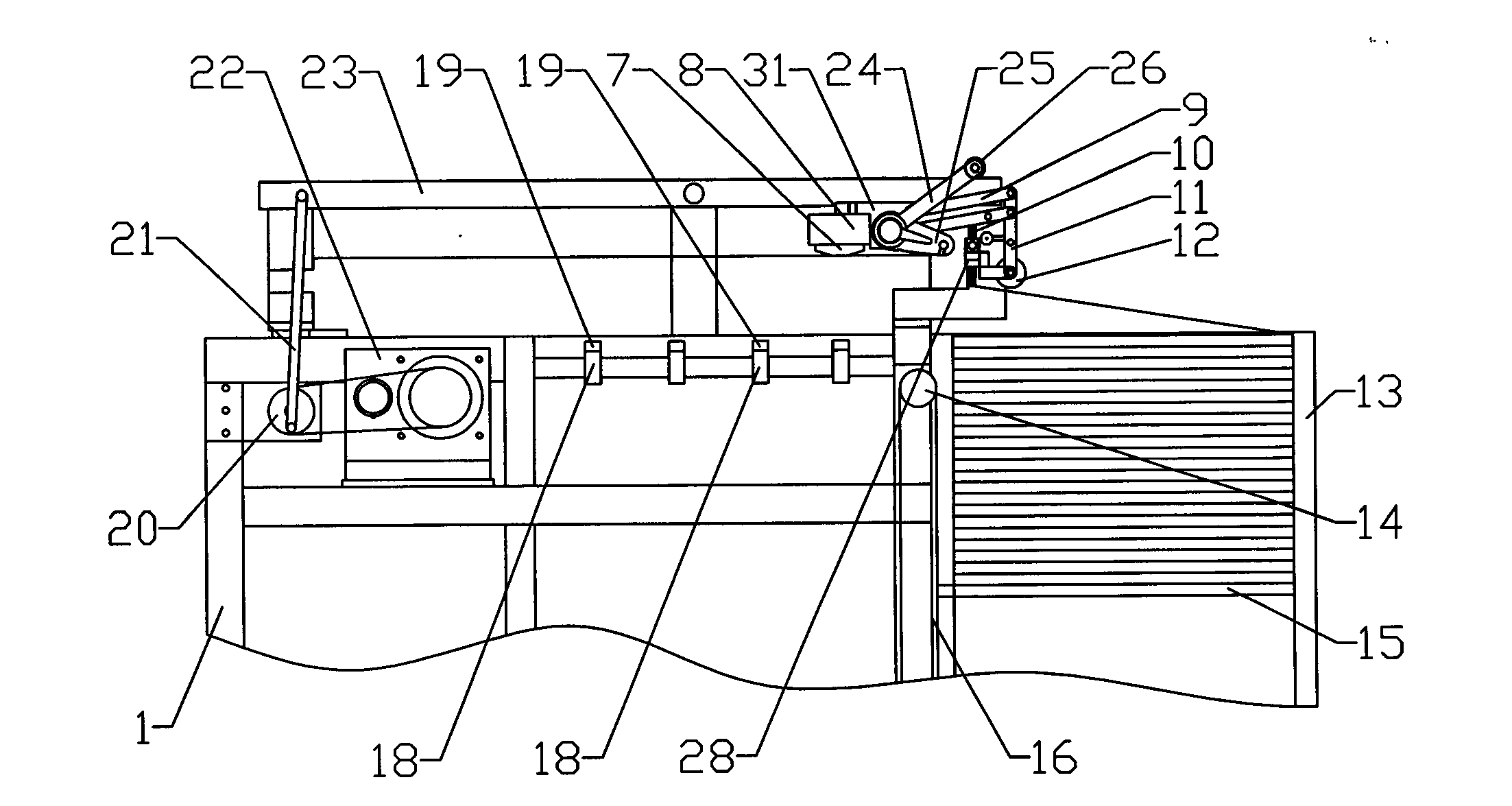

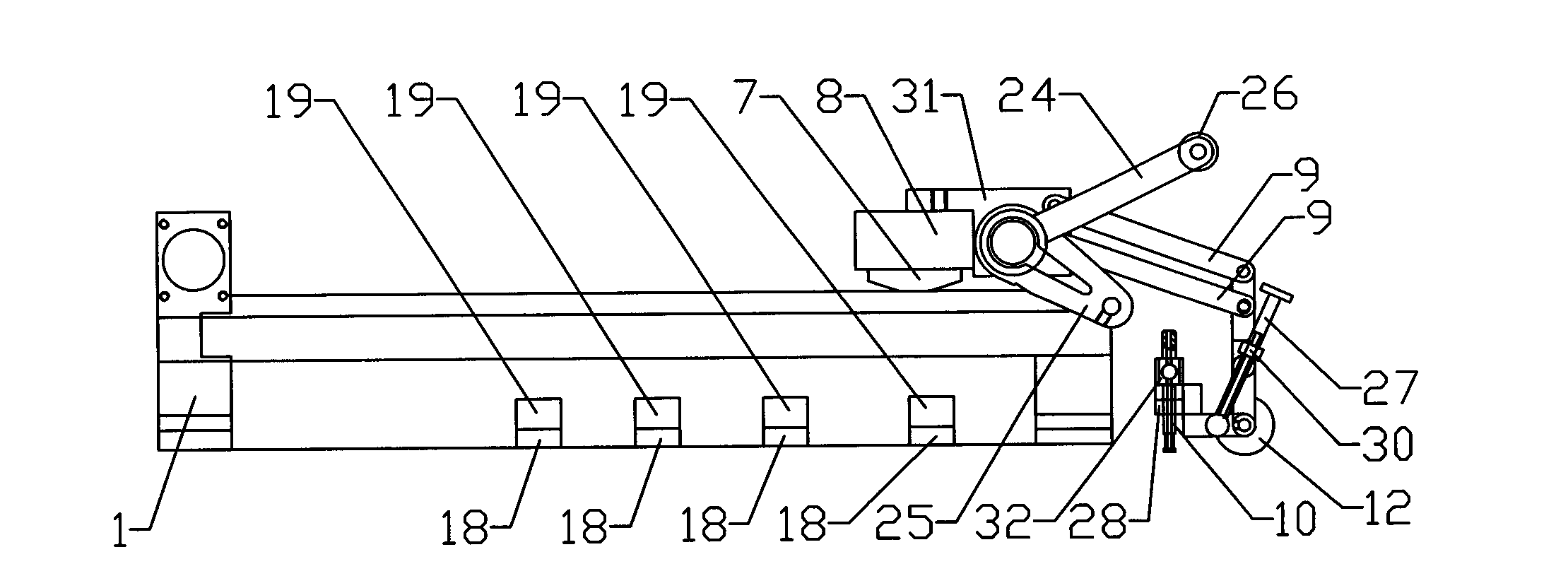

[0028] Example: as attached figure 1 As shown, a collating machine includes a frame 1, a paper conveying device is arranged on the upper part of the frame 1, and a plurality of groups of paper suction devices are arranged on the upper part of the paper conveying device, and a plurality of groups of suction devices are arranged on one side of the frame 1. The paper feeding device is a paper feeding device, and the paper suction device is connected with the power transmission device.

[0029] In this embodiment, the number of groups of paper suction devices is six groups, and the six groups of paper suction devices are evenly distributed along the longitudinal direction of the frame 1, and the number of paper supply devices is six groups, and each group of paper suction devices is correspondingly provided with a group of paper supply devices , compact structure, small footprint.

[0030] The number of groups of paper suction device and paper feeding device can be increased or d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com