Pit furnace with protective atmosphere device and automatic workpiece transferring device in quenching

A protective atmosphere and automatic transfer technology, applied in quenching devices, furnaces, heat treatment furnaces, etc., can solve problems such as inconvenient operation, poor safety, oxidation and decarburization of the workpiece surface, and achieve the goal of improving production efficiency, quality, and product quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

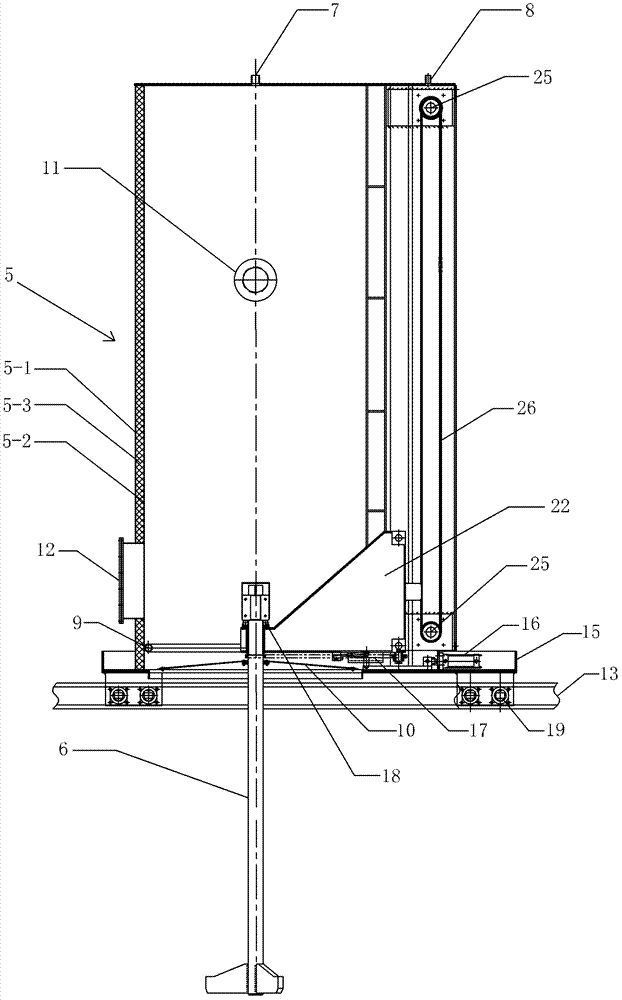

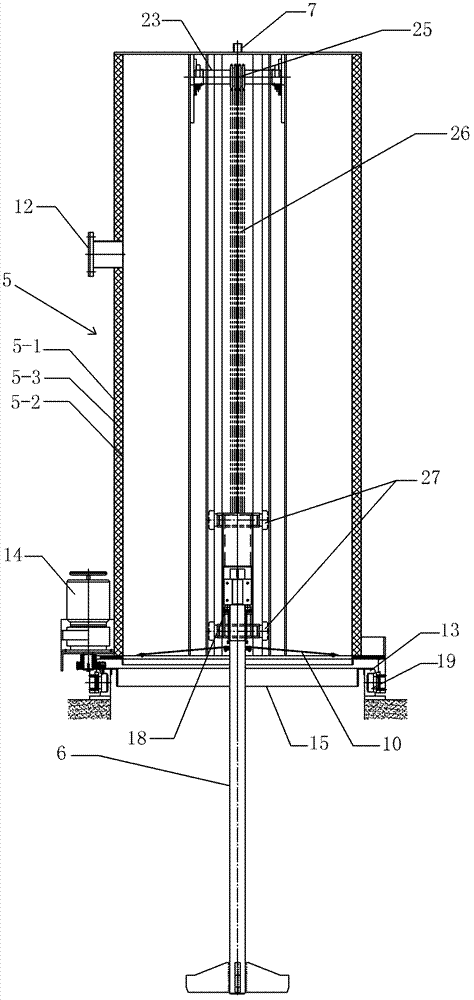

[0023] Figure 1-Figure 4 Constitute the specific embodiment 1 of the present invention.

[0024] refer to Figure 1-Figure 4 , the present embodiment includes a furnace body 1, a protective atmosphere device, a transfer device 2 and a control device are provided in the furnace body 1, the protective atmosphere device includes a protective gas input end 3 and a quenching tank 4, and the transfer device 2 includes a translation mechanism and up and down movement mechanism, the translation mechanism is connected with the shell 5, and the up and down movement mechanism is connected with the hook 6; the top of the shell 5 is provided with a first protective gas inlet 7 and an air exhaust port 8, and the shell 5 The bottom of the bottom is provided with a second protective gas inlet 9; the first protective gas inlet 7 and the second protective gas inlet 9 are each communicated with the protective gas input port 3 through an air valve; the control signal output of the control devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com