Unsupported Construction Structure and Construction Method of Circular Deep Foundation Pit

A construction method and unsupported technology, which can be used in foundation structure engineering, excavation, sheet pile wall, etc., can solve the problems of affecting the excavation speed of foundation pit, slow construction speed, waste of resources, etc. The effect of cost reduction and construction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

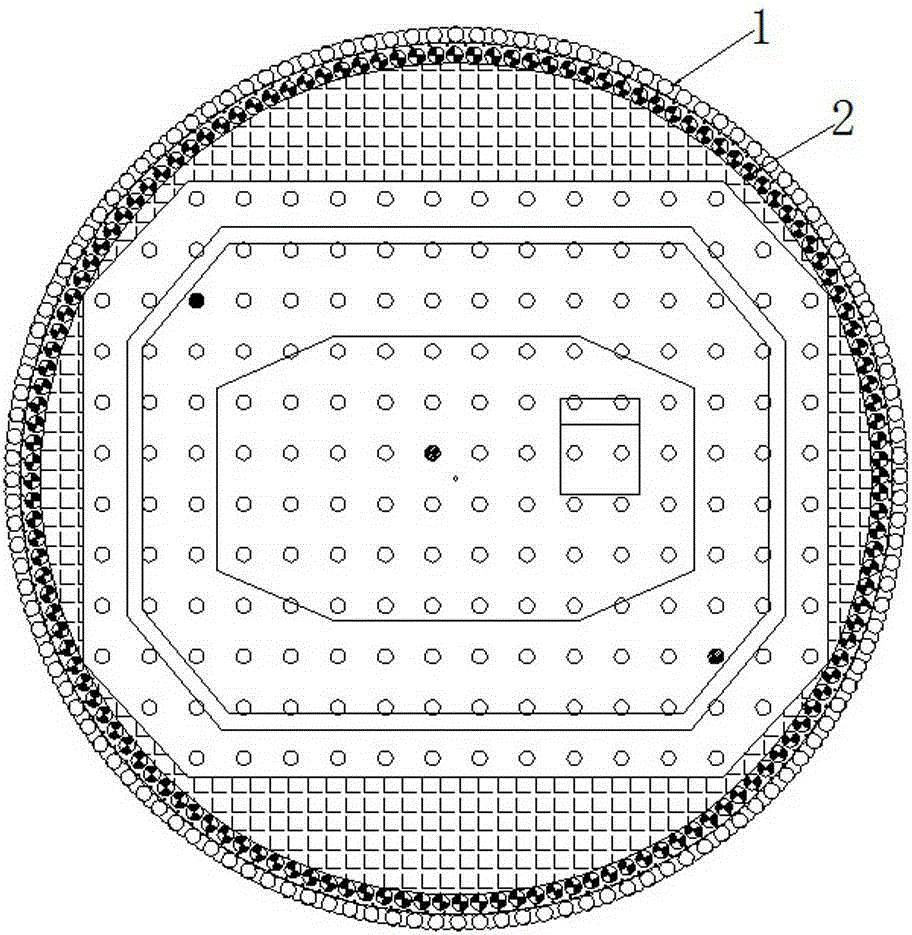

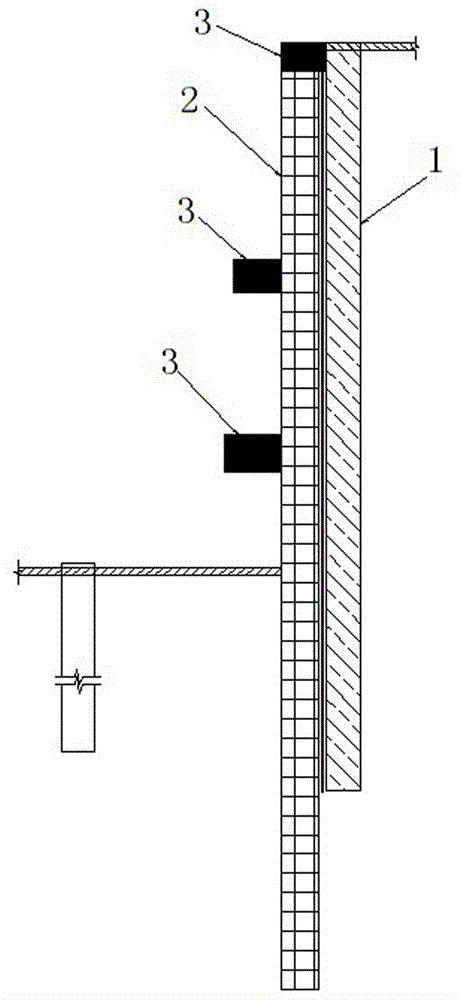

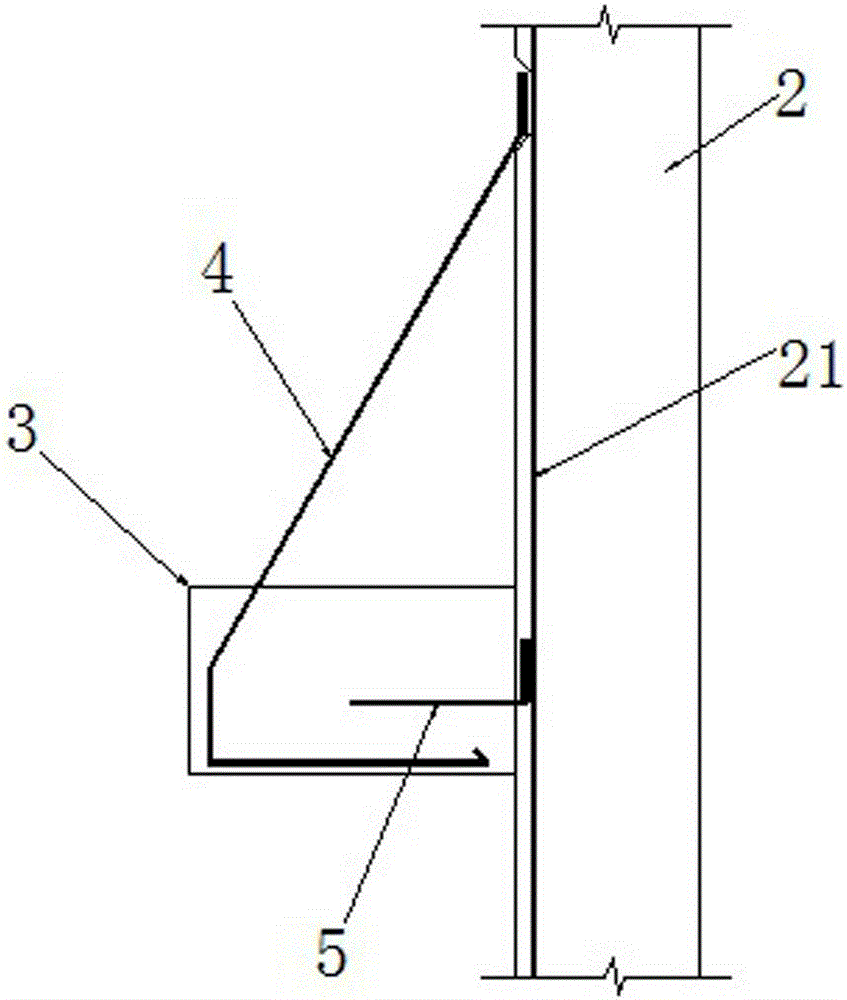

[0065] Embodiment 1: An unsupported construction structure of a circular deep foundation pit, which is provided with a circle of three-axis mixing piles 1, a circle of bored piles 2 and several purlins 3, and several of the three-axis mixing piles are surrounded by a circle And a continuous circle, some of the bored piles form a circle with intervals, the circle of three-axis stirring piles is located at the periphery of the circle of bored piles, and each of the purlins They are all circular shapes formed by one-time pouring, the first purlin is a crown beam, and the crown beam is poured on the pile top of the circle of bored cast-in-place piles, and the main reinforcement of the bored cast-in-place piles should be placed in the crown beam, The rest of the purlins are poured on the side of the inner ring of the circle of bored piles and are fixedly connected with the bored piles, and there is a distance between adjacent purlins in the vertical direction.

[0066] Except the c...

Embodiment 2

[0067] Embodiment 2: A kind of unsupported construction method of circular deep foundation pit, carry out according to the following steps:

[0068] (1) Site leveling: Before the construction of the three-axis mixer, the site must be leveled first, and the surface hard objects and underground obstacles in the construction area must be removed. In order to strengthen the load-bearing load, the method of padding the steel plate can be used to facilitate the walking of the pile frame;

[0069] (2) Measurement and setting out:

[0070] a. According to the measuring point provided by the construction unit as the reference point, arrange on-site measurement control points and elevation control points;

[0071] b. The measurement control point is arranged at the center of the foundation pit enclosure structure plane;

[0072] c. Measure and release the position of each three-axis mixing pile and each drilled cast-in-place pile pile by pile;

[0073] d. The three-axis stirring pile ...

Embodiment 3

[0105] Example 3: Take KONE Elevator (Kunshan) test tower foundation pit (the foundation pit completed floor pouring on March 15, 2012, and is now undergoing construction of the main structure), the project is located in the high-tech industrial park of Kunshan City, Jiangsu Province Inside, the height of the tower is about 235m above the ground, and it will become the tallest elevator test tower in the world after completion. The excavation depth of the foundation pit of this project is 15.10m, the plane shape is circular, and the diameter is 45.8m. Take the following construction steps:

[0106](1) Site leveling: site leveling, removal of surface hard objects and underground obstacles in the construction area;

[0107] (2) Measurement and setting out:

[0108] a. According to the measuring point provided by the construction unit as the reference point, arrange on-site measurement control points and elevation control points;

[0109] b. The measurement control point is arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com