Flexible hanging self-expansion operating platform and construction method

An operation platform and self-expanding technology, which is applied in the direction of building structure support, building structure support, building structure support scaffolding, etc., can solve the problems of many safety hazards, high cost of installing and dismantling hanging baskets and moving, and large amount of steel pipes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0074] (Example 1, flexible hanging self-expanding operating platform and construction method)

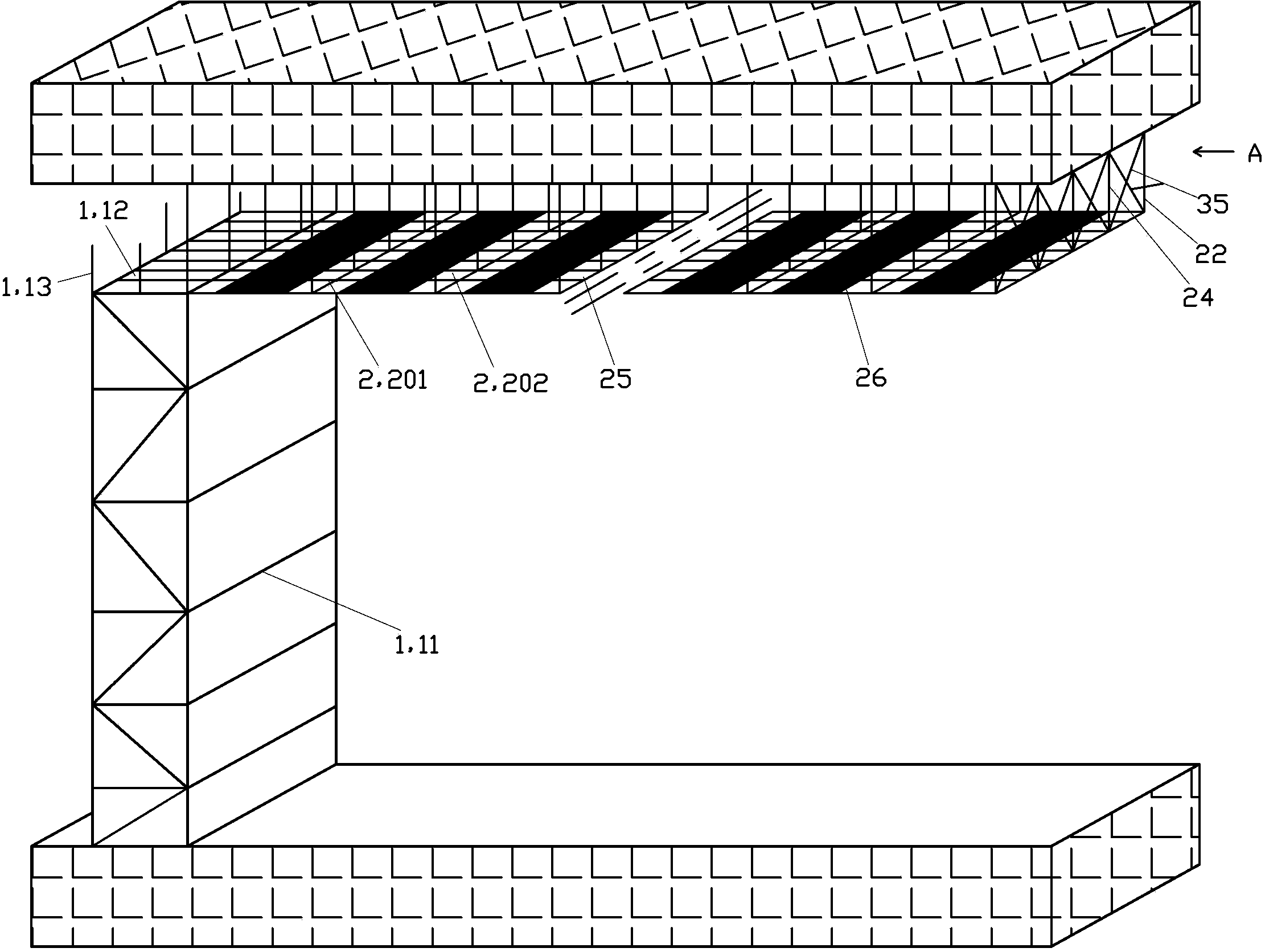

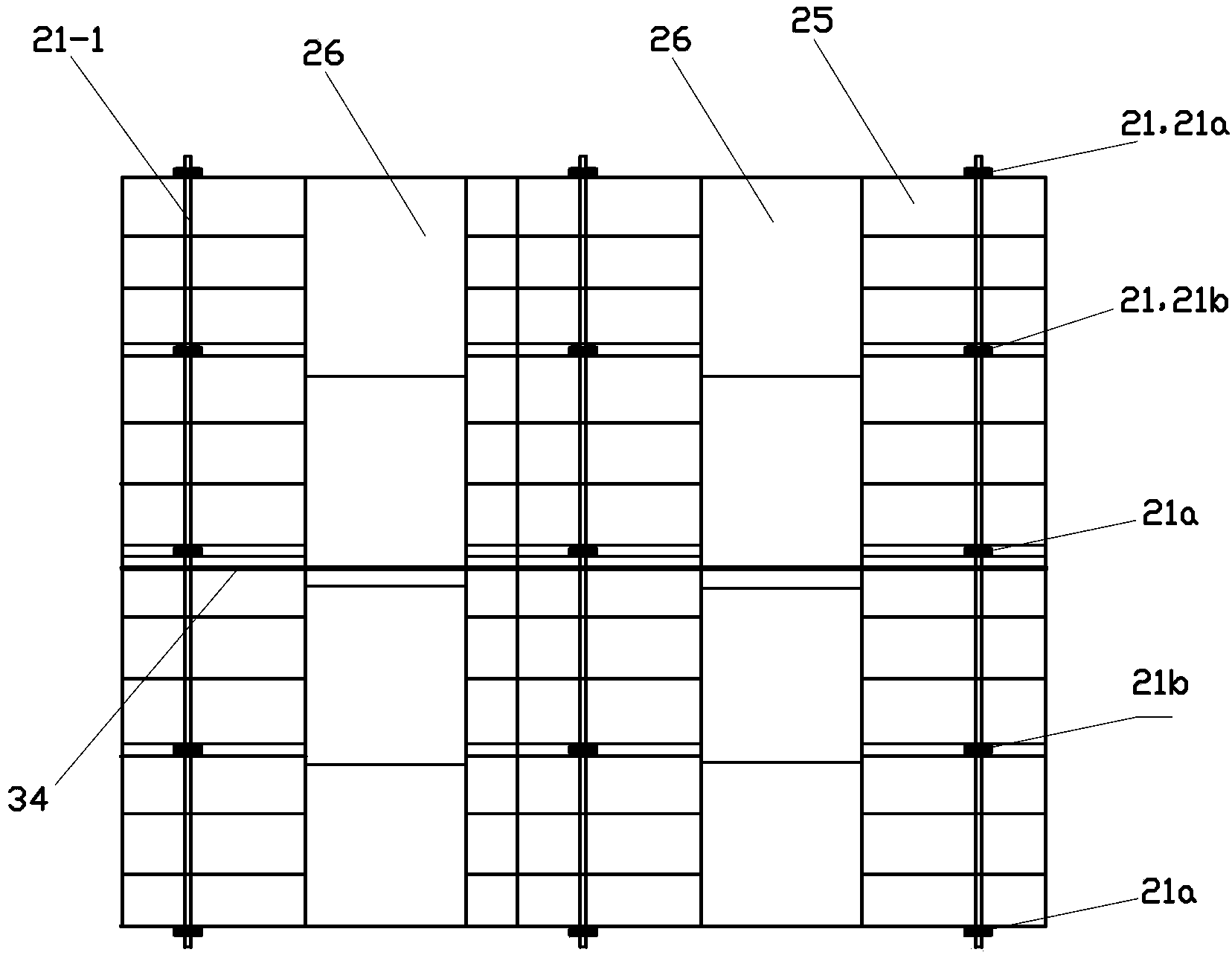

[0075] See Figure 1 to Figure 4 , the flexible hanging self-expanding operating platform of this embodiment includes an initial platform 1 , a platform standard room 2 , a safety protection device 3 and a construction auxiliary device 4 .

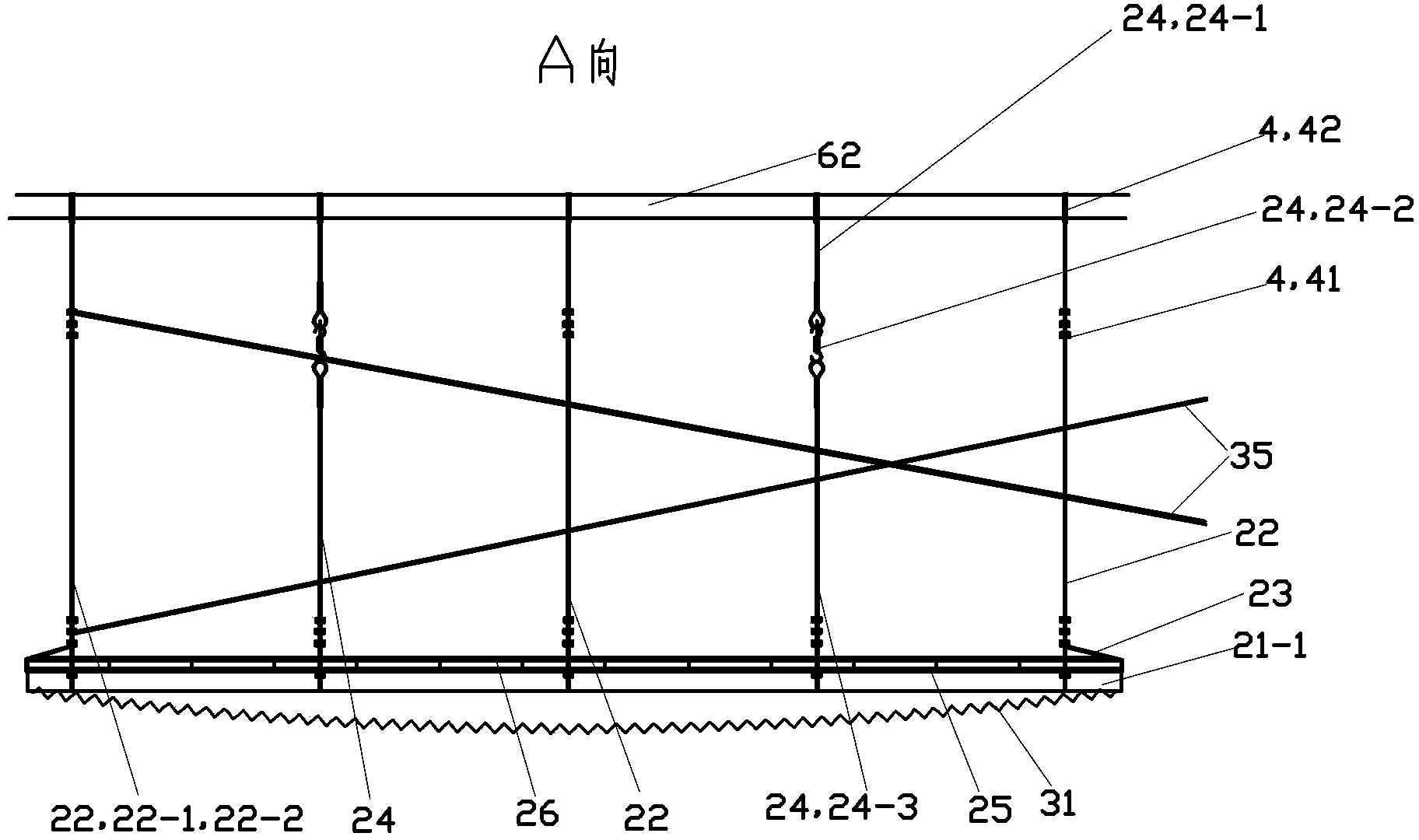

[0076] The construction aid 4 comprises a connection rope clip 41 and a protective rubber pad 42 . The protective rubber pad 42 is arranged between the contact surfaces of steel wire ropes and structures such as steel beams during use. The connecting rope clip 41 includes a first connecting rope clip 41-1, a second connecting rope clip 41-2, a third connecting rope clip 41-3, a fourth connecting rope clip 41-4 and a fifth connecting rope clip 41-5.

[0077] See Figure 6 , The connecting rope clamp 41 is composed of a connecting seat 41a, a U-bolt 41b and two corresponding nuts 41c; the connecting seat 41a is provided with two through holes....

Embodiment 2

[0134] (Example 2, flexible hanging self-expanding operating platform)

[0135] The rest of the flexible hanging self-expanding operating platform of this embodiment is the same as that of Embodiment 1, except that the top of the flexible hanging self-expanding operating platform of this embodiment used for the building body is the top of a reinforced concrete structure. Before pouring the top, special hook parts are welded and fixed on the top steel frame, or, according to the calculation during construction, a number of hanging bearing parts are pre-set on the top of the reinforced concrete structure, so that the main body of the building There is a hanging member facing downwards that is equivalent to the steel beam 61 and the steel beam 62 of Embodiment 1 at the top.

[0136] When the working wire rope 22-1 of the main hanging wire rope 22 is set, the end of its upper section passes through the corresponding two hook pieces (referring to the hook piece directly above the s...

Embodiment 3

[0138] (Example 3, flexible hanging self-expanding operating platform)

[0139] The rest of this embodiment is the same as Embodiment 1, except that the initial platform 1 of the flexible hanging self-extending operating platform of this embodiment is a movable platform. The movable platform is a platform on which roller components are arranged at the bottom of the structural body of the fastener type steel pipe scaffold. same length or slightly larger.

[0140] After completing the setting up of the first row of platform standard rooms 2 in the forward and backward direction, move the movable scaffold 11 to the left side of the position of the new front and rear adjacent platform standard room 2 that needs to be built along the front and rear direction, and then carry out The erection of a new row of platform standard rooms 2, and the aluminum alloy square tube 21-1 of the new row of platform standard room 2 and the corresponding aluminum alloy square tube 21-1 of the previo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com