Front canopy automatic water curtain of digging and blasting working surface and working method thereof

A technology for probing beams and working faces, which is applied in earthwork drilling, safety devices, mining equipment, etc. It can solve problems such as spray heads being easily damaged by blasting, poor dust-proof water quality, and easy burning of solenoid valves, etc., achieving increased Dust reduction effect, easy to carry and install, compact structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

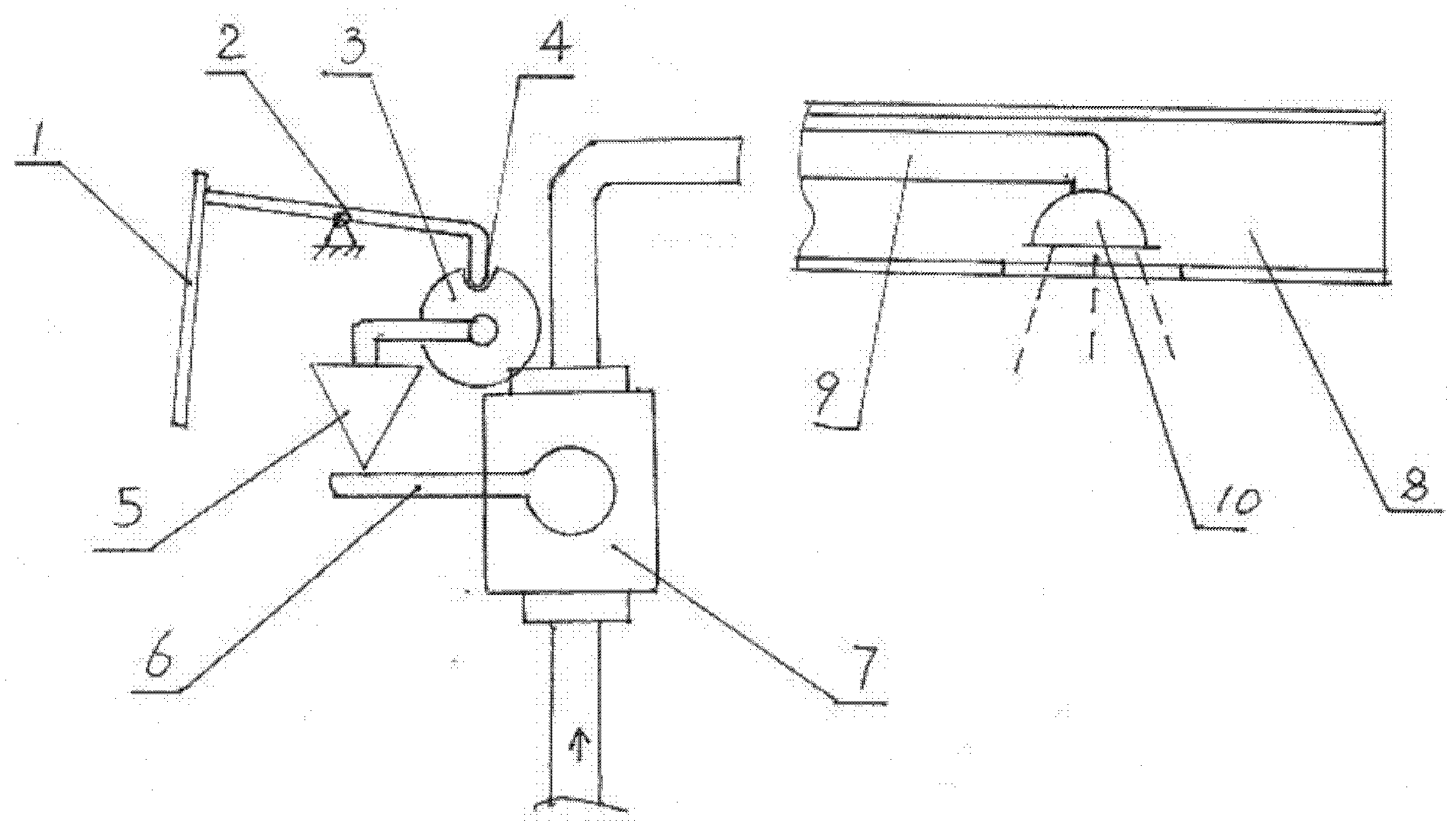

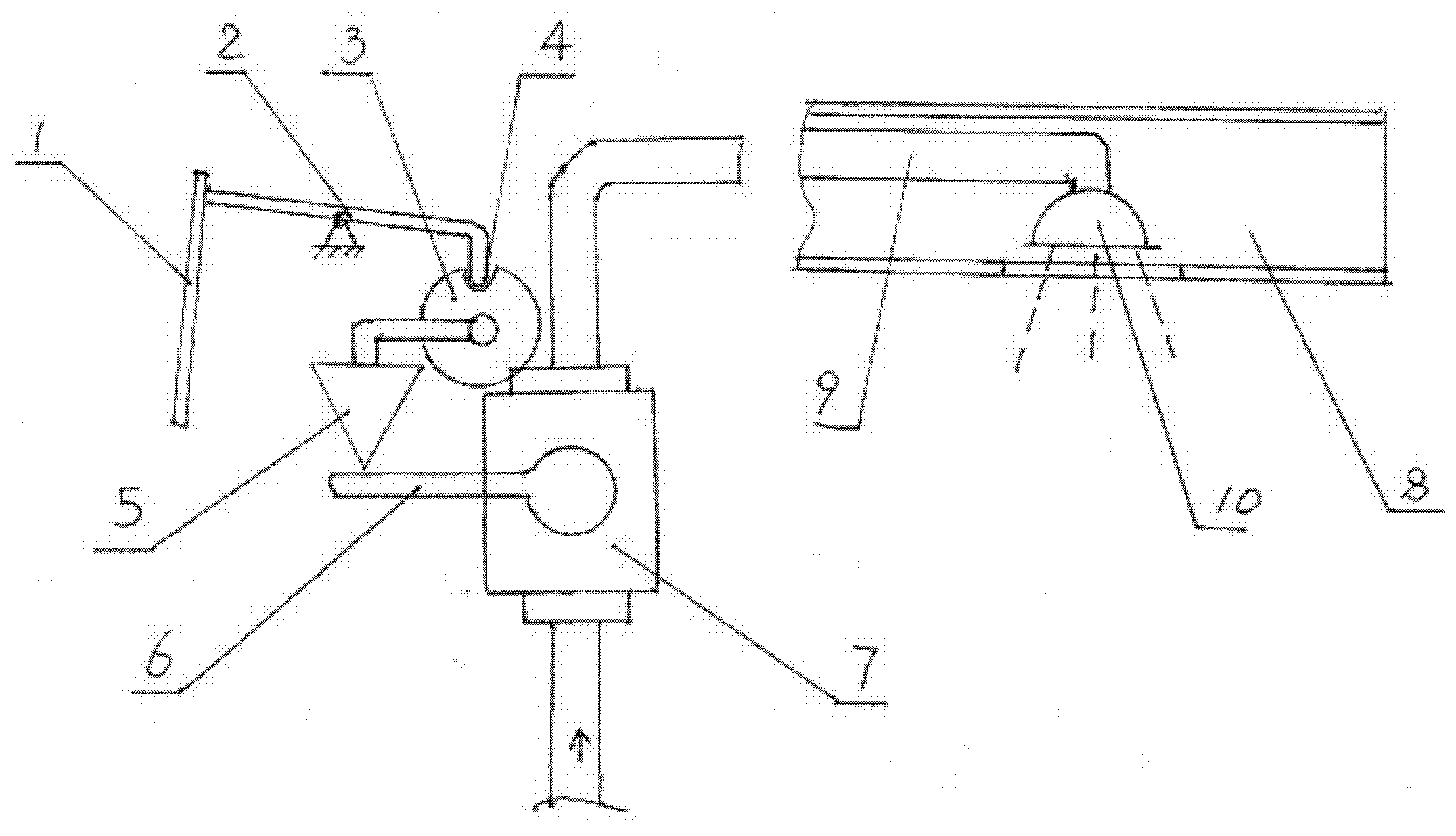

[0013] Such as figure 1 As shown, the present invention includes a nozzle 10, a water pipe 9 and an automatic control device. The nozzle 10 is installed in the inner groove of the front beam 8 at a distance of 1-2 meters from the blasting working face; The rear end; after the water pipe 9 is connected with the nozzle 10, it extends from the inner groove of the front probe beam 8 to the rear end of the front probe beam 8, and is connected with the water outlet of the automatic control device; the structure of the automatic control device is: it includes Water valve 7, impact plate 1, support rod, chuck 3, weight 5 and linkage mechanism 2; weight 5 is connected to the rotatable chuck 3 through the support rod, and weight 5 is in the handle of water valve 7 under normal conditions The closed position; the impact plate 1 is fixed on one end of the link mechanism 2, and the plate surface is facing the blasting impact direction; the other end of the link mechanism 2 is stuck in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com