Hot and dirty coal gas boiler

A gas-fired boiler and hot dirty gas technology, which is applied in the combustion of block fuel and gaseous fuel, the combustion of liquid fuel and gaseous fuel, the combustion of gaseous fuel and powder fuel, etc., to achieve significant economic benefits and energy supply. Nervous, easy-to-use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

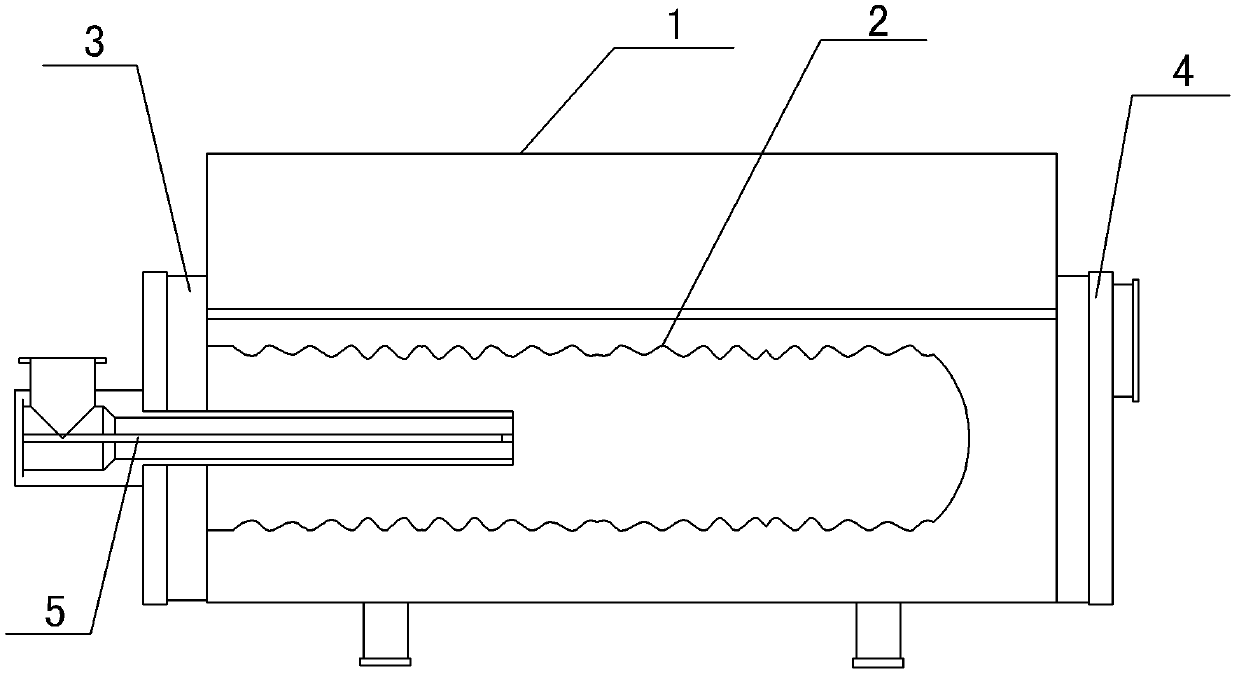

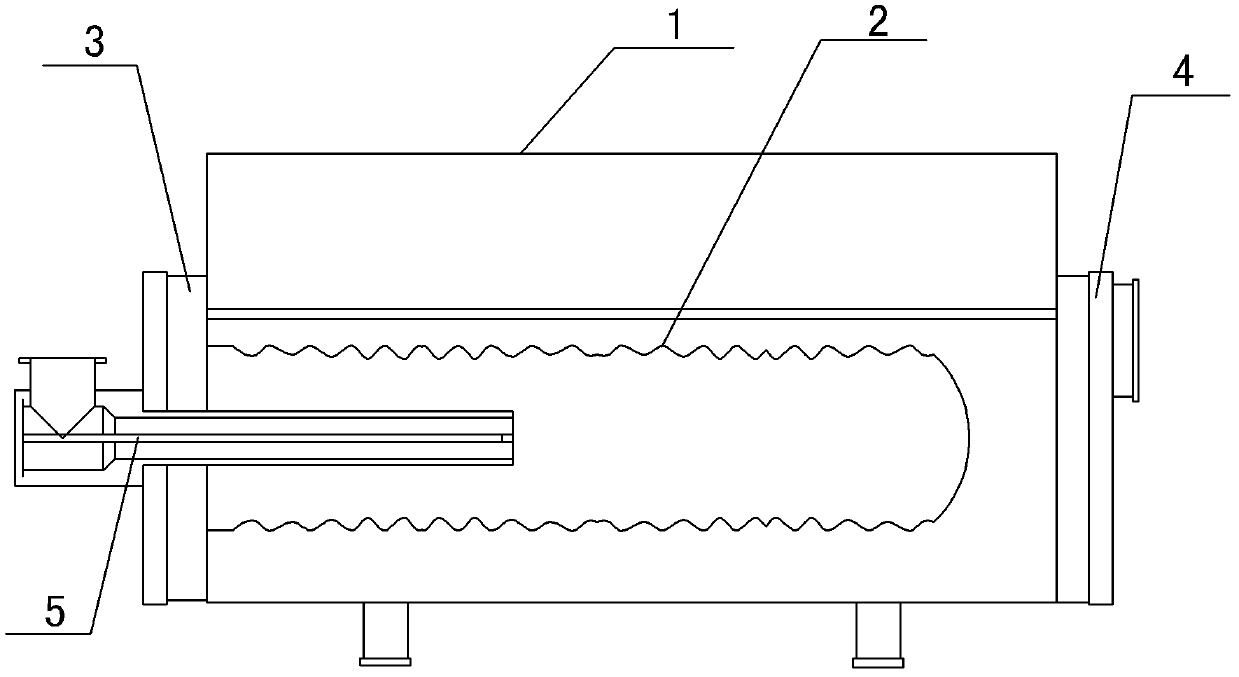

[0021] Such as figure 1 As shown, the hot dirty gas gas boiler described in this embodiment includes a horizontal internal combustion three-pass gas boiler body 1, a horizontal internal combustion three-pass gas boiler body 1 with a built-in waveform furnace 2, a horizontal internal combustion three-pass gas The front end of the boiler furnace body 1 is provided with a movable front smoke chamber 3, and the rear end is provided with a movable rear smoke chamber 4, and a burner 5 is connected between the movable front smoke chamber 3 and the waveform furnace 2, which is located in the waveform furnace 2 The length of the burner 5 is 1 / 3 of the length of the corrugated furnace 2.

[0022] Among them, due to the use of hot dirty gas as fuel, the generated flue gas contains more dust and impurities, and the horizontal internal combustion three-pass gas boiler body 1 is prone to dust accumulation, which will affect the thermal efficiency of gas combustion, so , The front and rear ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com