Gas stove capable of controlling multiple gas nozzles in grouping manner

A technology for gas nozzles and gas stoves, which is applied in the field of gas stoves and can solve the problems of shorter flames, lower jet speeds, and low thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

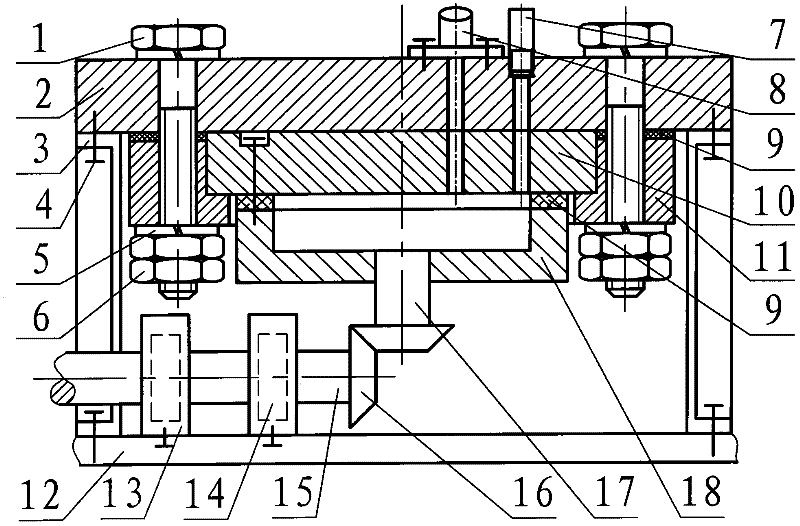

[0063] Combine below Figure 1 to Figure 17 To further illustrate the present invention: a gas stove that controls a plurality of gas nozzles in groups, including a flame control device, is characterized in that:

[0064] There are three to one hundred groups of gas nozzles 7 of the flame control device, wherein at least one group has two to fifty gas nozzles; the total number of gas nozzles 7 is four to three hundred.

[0065] The angle between the axis of each gas nozzle 7 and the horizontal plane is 45°-90°.

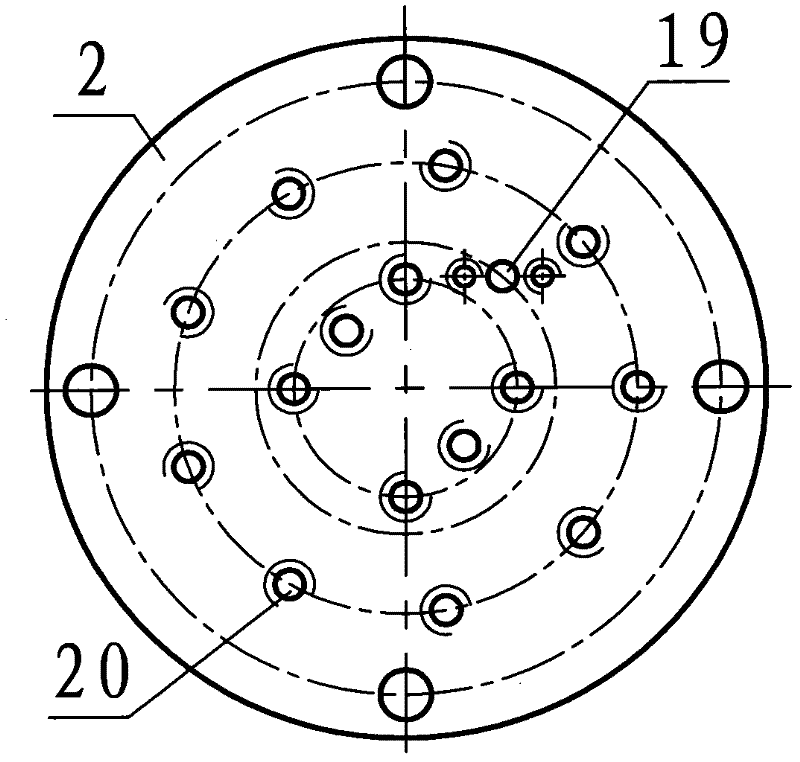

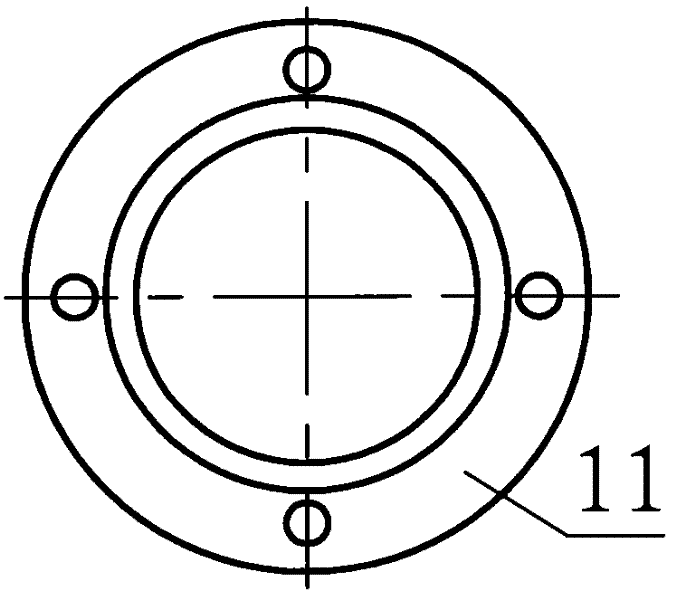

[0066] A gas nozzle plate 2 is provided, the gas nozzle plate 2 is provided with a gas outflow through hole 20 with an internal thread, and a gas nozzle 7 is installed on the gas outflow through hole 20 with an internal thread; a flame is set under the gas nozzle plate 2 Adjusting plate 10, a gas storage chamber is arranged under the flame adjusting plate 10; the flame adjusting plate 10 is installed on the lower surface of the gas nozzle plate 2 by a positioning cla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com