Light beam array membrane stress measuring device

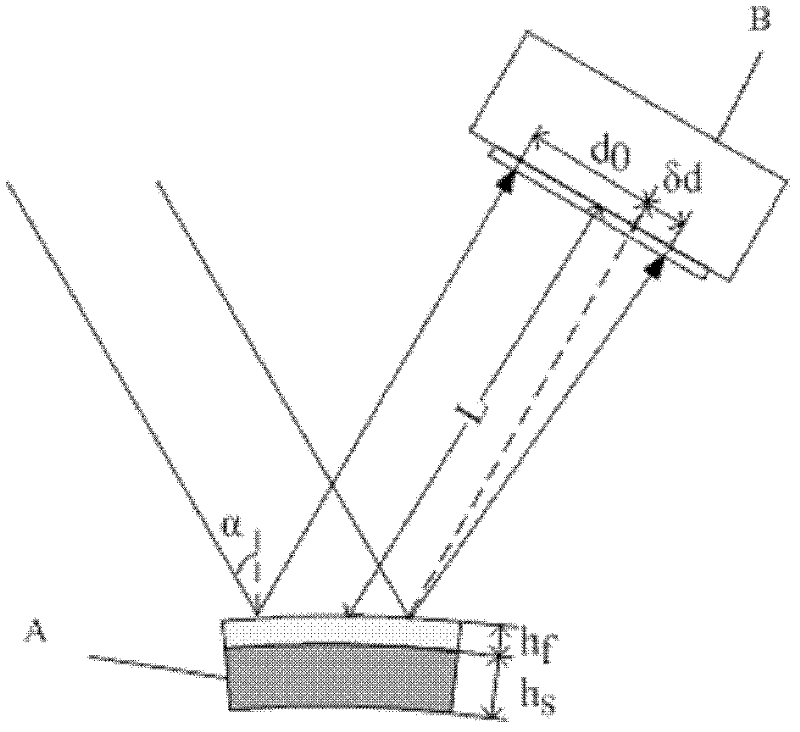

A technology of array light beams and measuring devices, which is applied in the direction of measuring the force of changes in optical properties of materials when they are stressed, to eliminate stress measurement errors and improve measurement accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

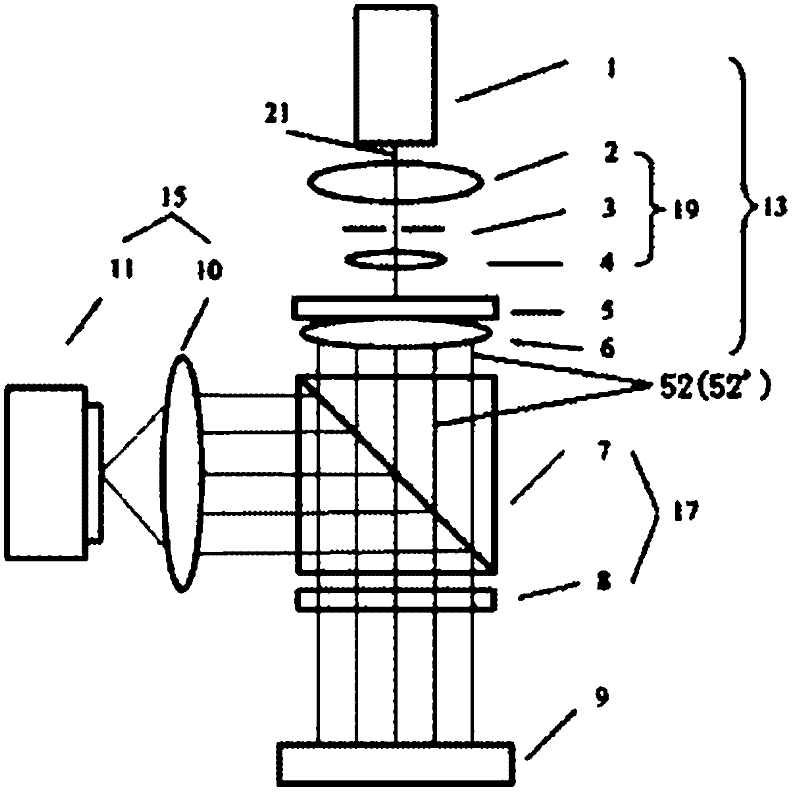

[0023] In order to make the array beam thin film stress measurement device of the present invention easier to understand, the technical solution of the present invention will be described in further non-limiting detail below in combination with two preferred embodiments and accompanying drawings.

[0024] refer to figure 2 , an array beam film stress measuring device, comprising a multi-beam pattern generator 13, a beam position detector 15 and a beam position separator 17, wherein the multi-beam pattern generator 13 and the beam position detector 15 are arranged perpendicular to each other.

[0025] The multi-beam pattern generator 13 includes a laser 1 , an inverted telescopic collimating optical system 19 , a beam splitter 5 and a collimating lens 6 . Wherein, the inverted telescopic collimation optical system 19 is composed of two lenses 2, 4 and a diaphragm 3 located between the two lenses 2, 4.

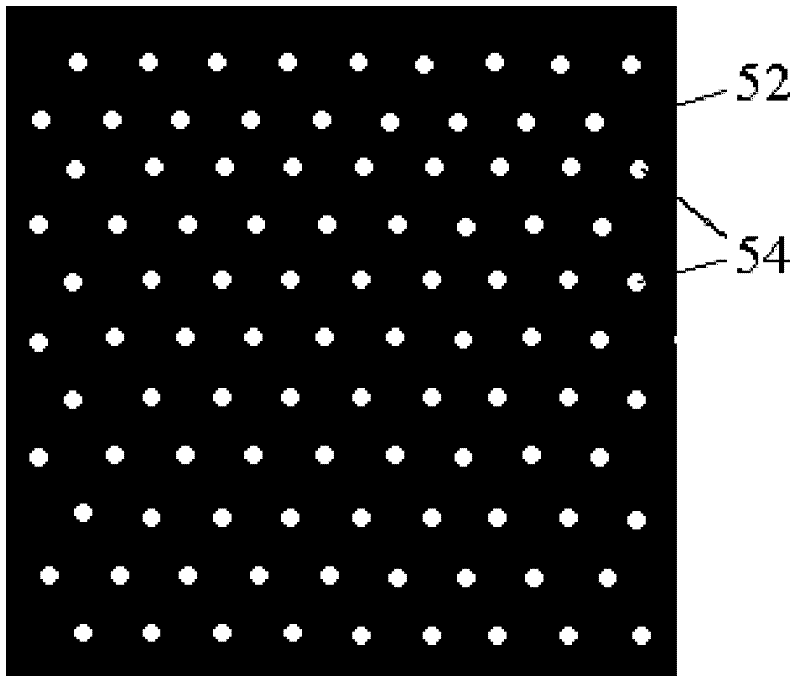

[0026] further reference image 3 and Figure 4 , the above-mentioned b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com