Gas sensor

A gas sensor and external gas technology, applied in instruments, scientific instruments, measuring devices, etc., can solve the problems of inability to miniaturize and large structure of the gas sensor, and achieve the effect of fewer structural parts, fewer process steps, and simpler assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings, but the protection scope of the present invention should not be limited thereby.

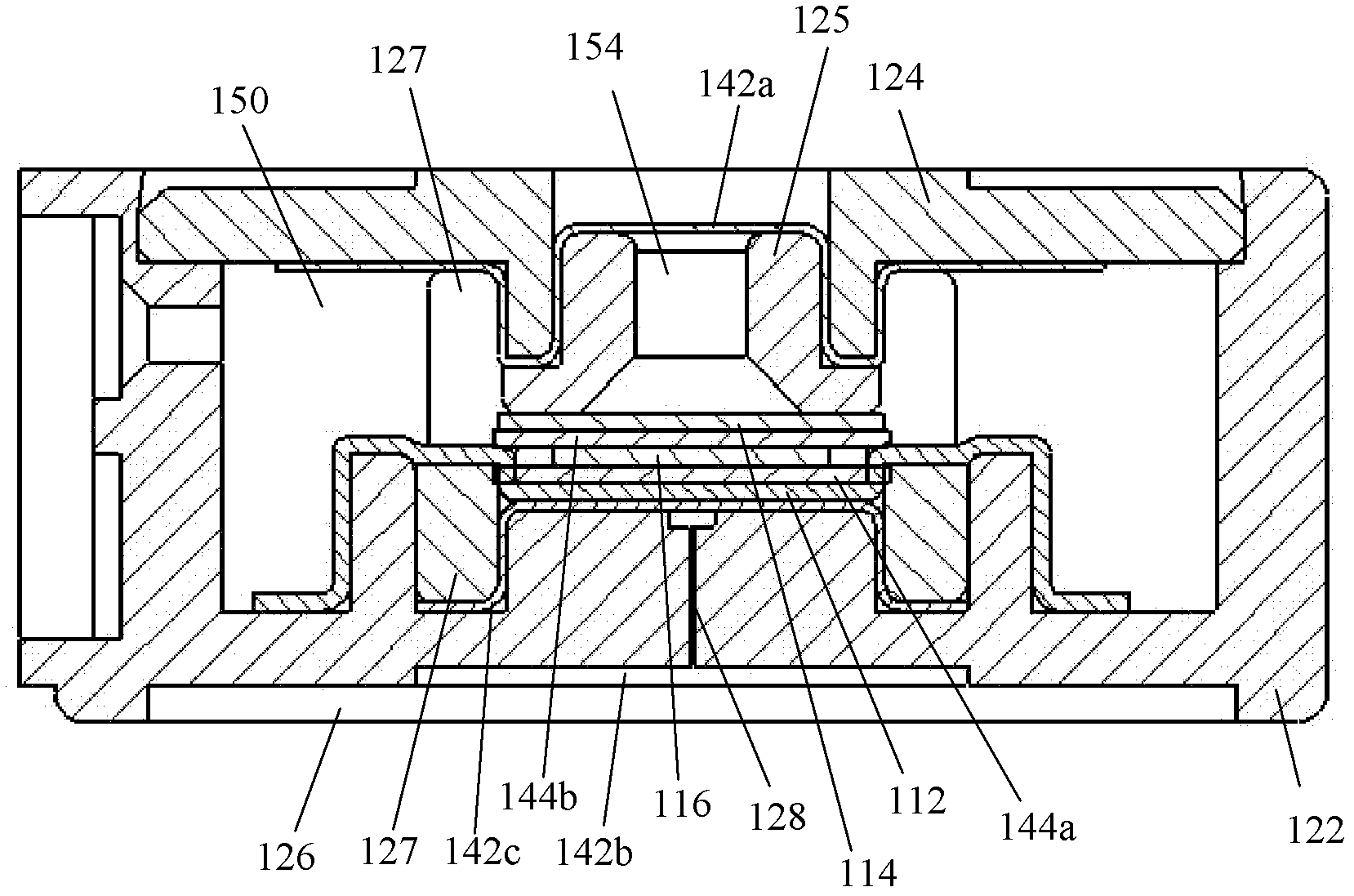

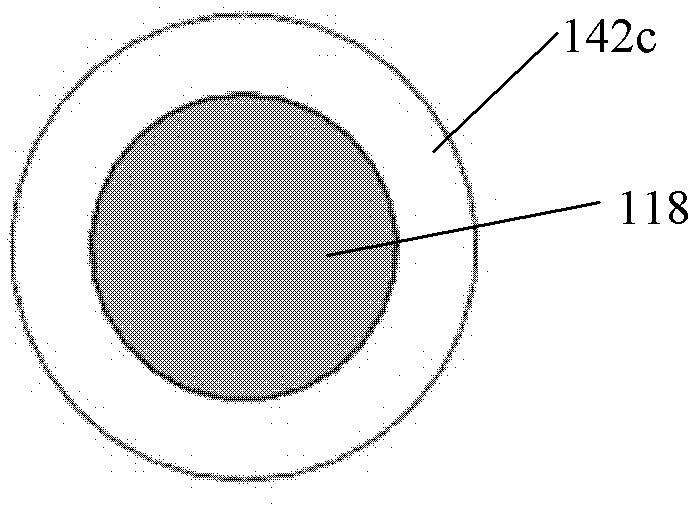

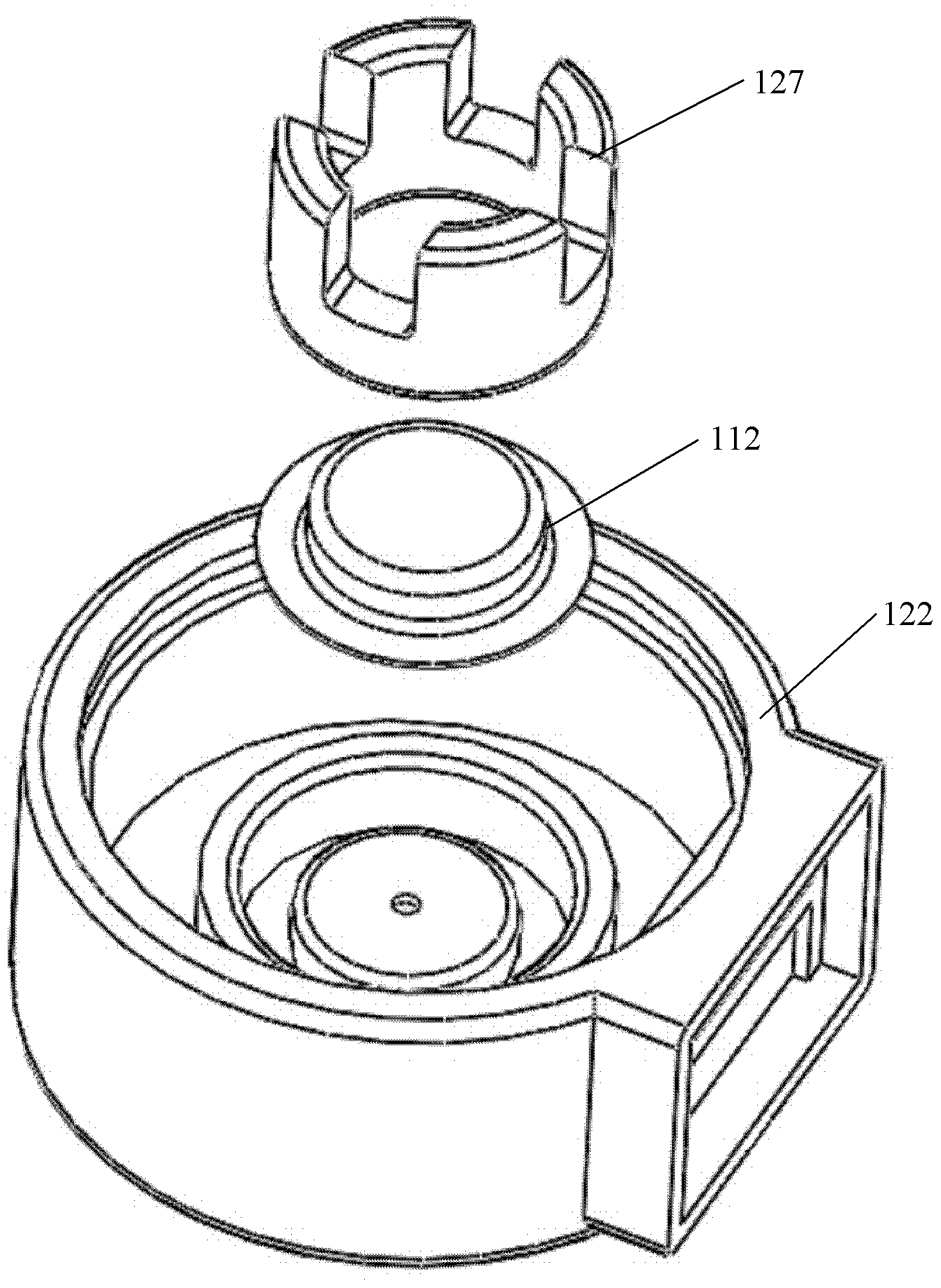

[0031] figure 1 A cross-sectional structure diagram of the gas sensor of this embodiment is shown, the gas sensor mainly includes: a housing 122, a housing cover 124, a bracket 127, a plug 125, a measuring electrode 112, a first liquid-absorbing material layer 144a, and a counter electrode 114, In addition, it also includes a second liquid-absorbing material layer 144b, a reference electrode 116, a first breathable and waterproof membrane 142a, a second breathable and waterproof membrane 142b, a dustproof membrane 126, and a third breathable and waterproof membrane 142c.

[0032] Wherein, the material of the housing 122 , the housing cover 124 , the bracket 127 and the plug 125 can be plastic. The outer shape of the housing 122 is cylindrical or nearly cylindrical. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com