Online pipeline flaw detection device

A flaw detection device and pipeline technology, applied in the direction of material magnetic variables, etc., can solve the problems of unreliable detection of online industrial pipelines, inapplicable online non-destructive testing of online pipelines, automatic crawling of online industrial pipelines, etc., to achieve compact structure, easy operation, convenience and safety Detection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

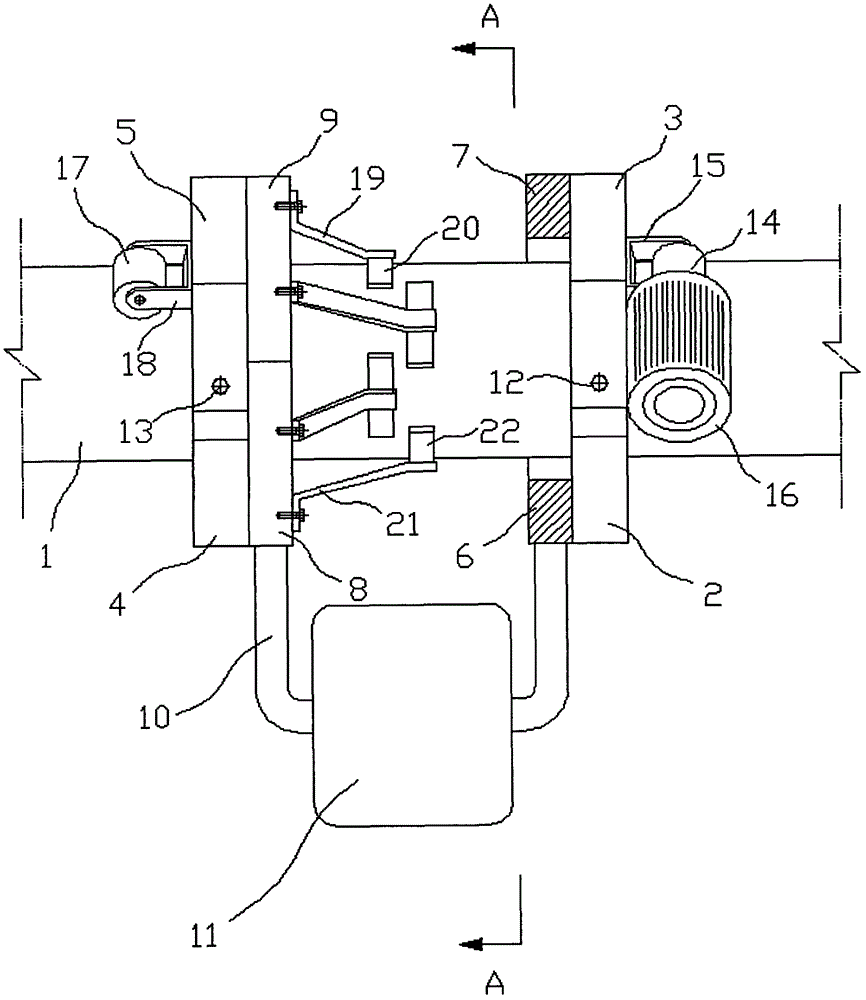

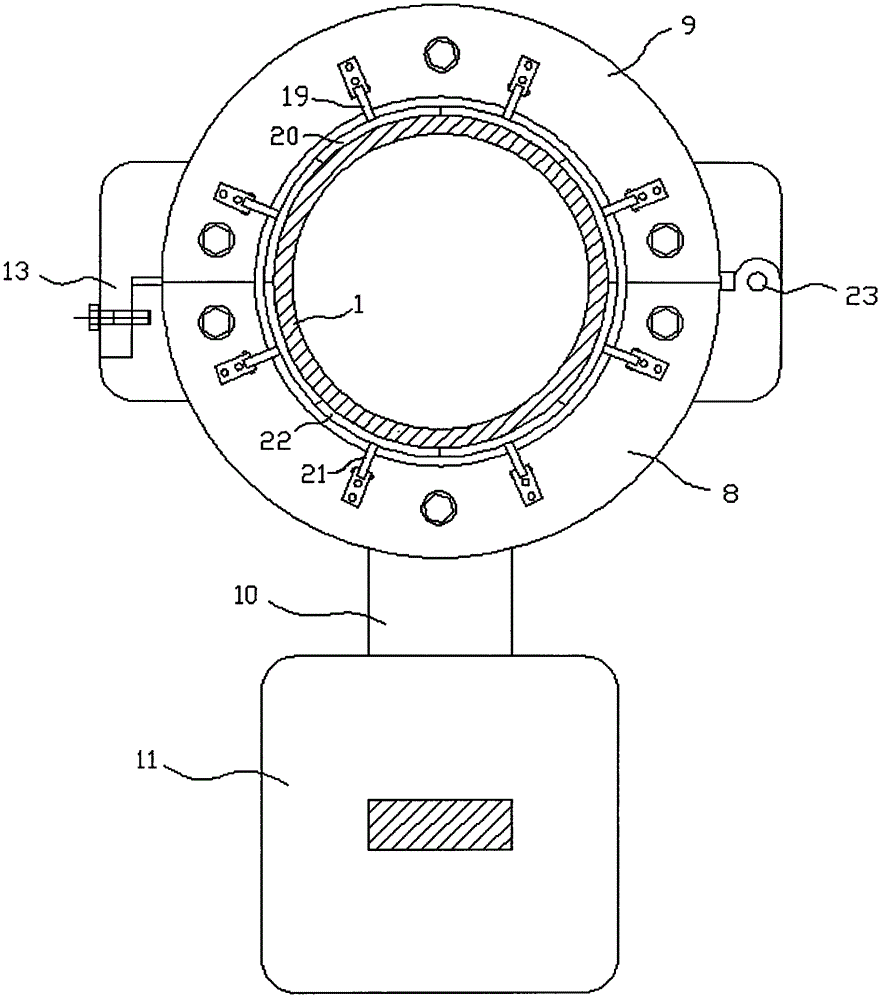

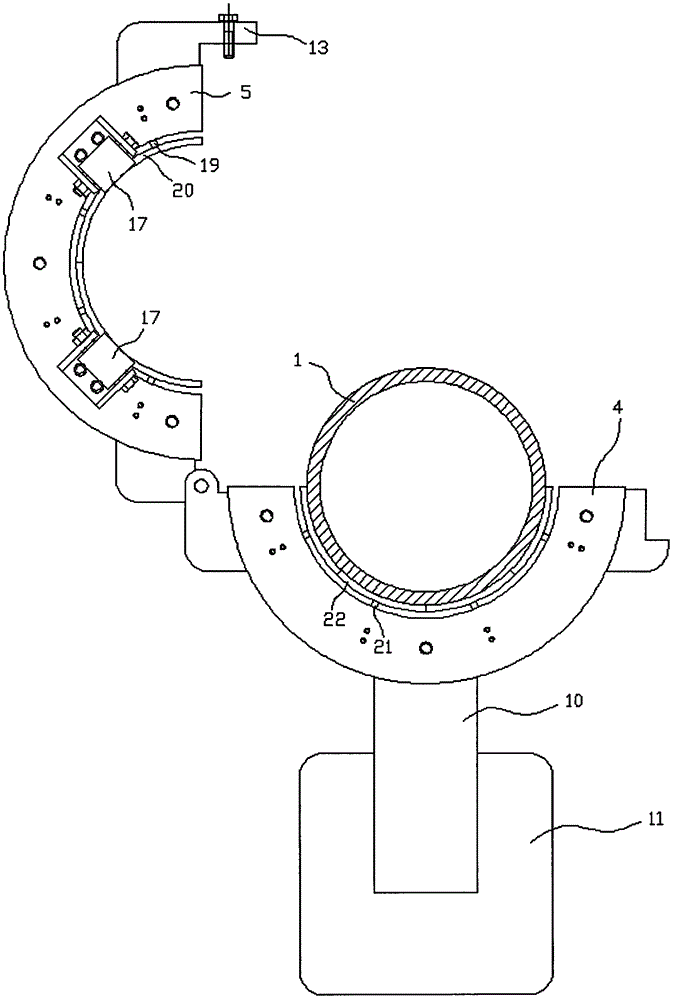

[0032] This embodiment is an online pipeline flaw detection device for detecting industrial pipelines with a diameter of about 177.8 mm, which consists of a magnetization mechanism, a probe and a crawling mechanism.

[0033] exist figure 1 , the magnetization mechanism includes a left ferromagnetic ring, a right ferromagnetic ring, a U-shaped column and a coil.

[0034] Among them, two sets of ferromagnetic rings are located on the left and right sides. One group of ferromagnetic rings on the right is formed by a semicircular right lower magnetic part 6 and a semicircular upper right magnetic part 7. Wherein the lower right magnetic part 6 of lower semicircular ring is bolted on the inside of the same lower right end plate 2 of the lower semicircular shape made of aluminum plate, and the upper right magnetic part 7 of upper semicircular is bolted on the inner side of the lower right end plate 2 made of aluminum plate. The inner side of the upper right end plate 3 of the same...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com