Oblique-incidence ultrasonic flaw detection method for barrel-type forging

An ultrasonic and oblique incident technology, which is applied in the direction of analyzing solids using sound waves/ultrasonic waves/infrasonic waves, can solve problems such as reducing the missed detection rate of ultrasonic flaw detection, and achieve the effects of reducing the missed detection rate of flaw detection defects, broadening the flaw detection range, and combining scientifically and reasonably

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0060] Embodiment (process number A), concrete steps are as follows:

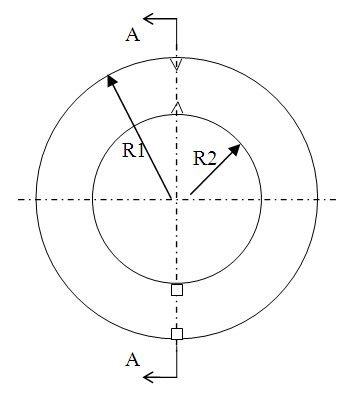

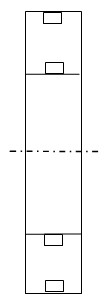

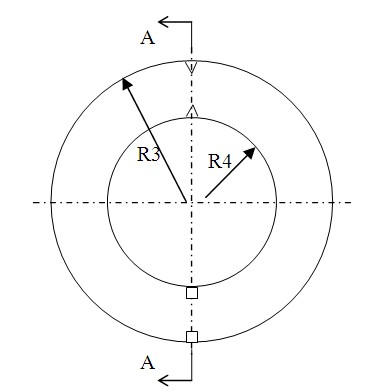

[0061] see Figure 9 As shown, 4130 material, specification: Φ433×Φ113×814mm, that is, the outer diameter is 433mm, the inner diameter is 113mm, and the axial length is 814mm.

[0062] Instrument model: CTS-9009, instrument number: 53831010202

[0063] Probe model: Φ20 6 degrees R250, probe number: E118409

[0064] Test block model: 4130-VR-098070 RR250177 (refraction angle 45 degrees contrast test block, serial number: 113557), 4130-VR-098055 RR250140 (refraction angle 34 degree comparison test block, serial number: 113559), 4130-VR-098037 RR250095 (Contrast test block with an incident angle of 10 degrees, serial number: 113550), 4130-VR-098022 RR250057 (comparative test block with an incident angle of 6 degrees, serial number: 113558)

[0065] Instruments, probes and test blocks are calibrated according to the 80% wave height sensitivity of the artificial V-shaped inner groove.

[0066] The flaw detec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com