Low-voltage electric fire prevention and detection device

A technology of fire prevention and detection device, applied in the direction of fault location and other directions, can solve the problems of high temperature of power supply line, fire, and low cost, and achieve the effect of low cost and prevention of electrical fire

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with accompanying drawing:

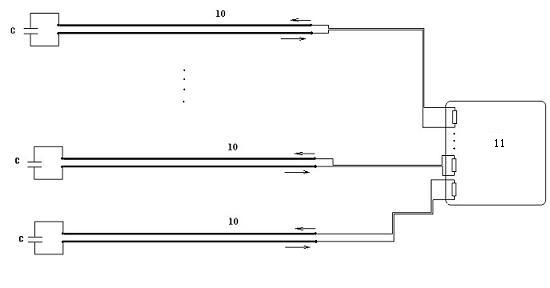

[0036] The low-voltage electrical fire prevention detection device of the present invention is mainly composed of at least one set of detection cables 10 , capacitor C and multi-channel intelligent detectors 11 . Multiple intelligent detectors 11 are connected to one end of each group of detection cables 10, and the other end of each group of detection cables 10 is connected to a capacitor C to form a loop. The multi-channel intelligent detector 11 can send an AC signal back through the capacitor C, so as to detect whether the entire detection cable is in a normal state. Such as figure 1 shown.

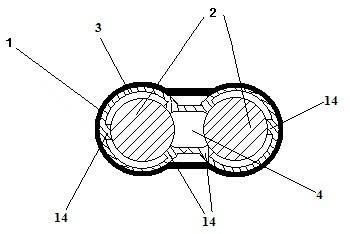

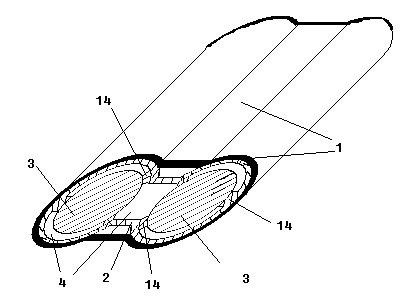

[0037] The detection cable 10 is a flat shape, such as figure 2 and image 3 shown. The detection cable 10 is composed of a heat-shrinkable tube 1 , a metal wire 2 and an isolated plastic tube 3 . Such as figure 2 shown. There are two metal wires 2, which are arranged in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com