Ferrule with alignment pin channels

A technology for aligning pins and channels, applied in the field of MT sleeves, can solve problems such as performance degradation, and achieve the effect of simplifying the molding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

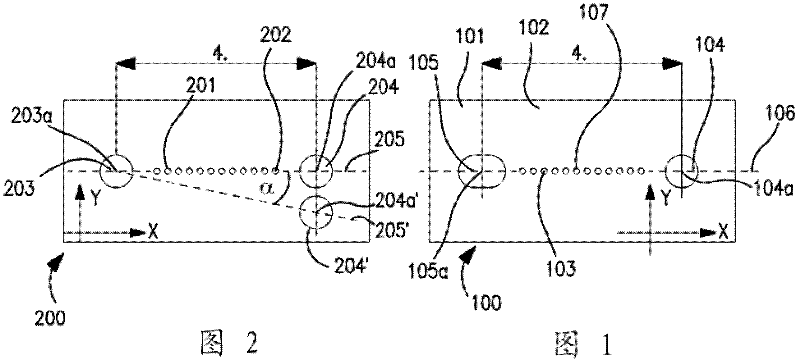

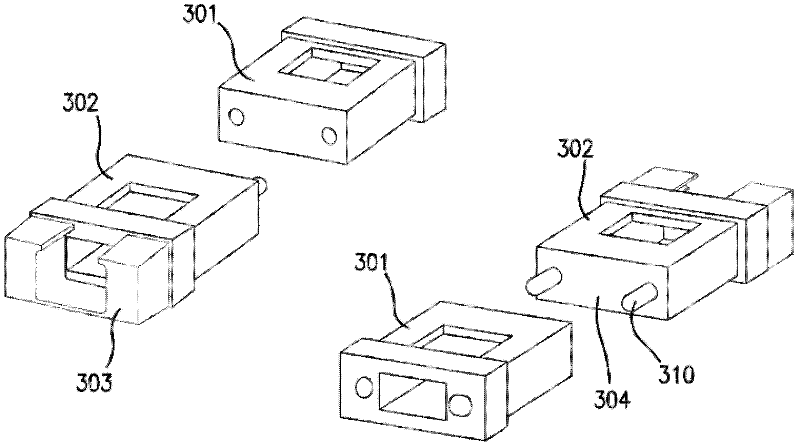

[0020] refer to figure 1 , shows an embodiment of the sleeve 100 of the present invention. The bushing 100 includes a body 101 defining an end face 102 . One or more channels 103 extend from the end face 102 through the body 101 . Each channel 103 is adapted to receive an optical fiber (not shown). The ferrule body also defines first and second alignment pin channels 104,105. Each alignment pin channel has a center point 104a, 105a disposed along a first axis 106 (dashed line). The first alignment pin channel 104 has an alignment pin 310 (see image 3 ) is substantially the same cross-section as the first cross-section and is adapted to receive an alignment pin. The second alignment pin channel 105 has a second cross-section elongated along the first axis 106 . Each element is considered in detail below and with respect to alternative embodiments.

[0021] The main body 101 of the ferrule is used to define a fiber optic channel 103 and alignment pin channels 104, 105, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com