PLC (programmed logic controller)-based redundancy system implementation method

An implementation method and technology of redundant system, applied in the field of PLC-based redundant system implementation, can solve the problems of high system cost, no further system research on the redundancy performance of soft redundant system, etc., and achieve low system cost and automatic failure. The effect of identification and positioning, and high system reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

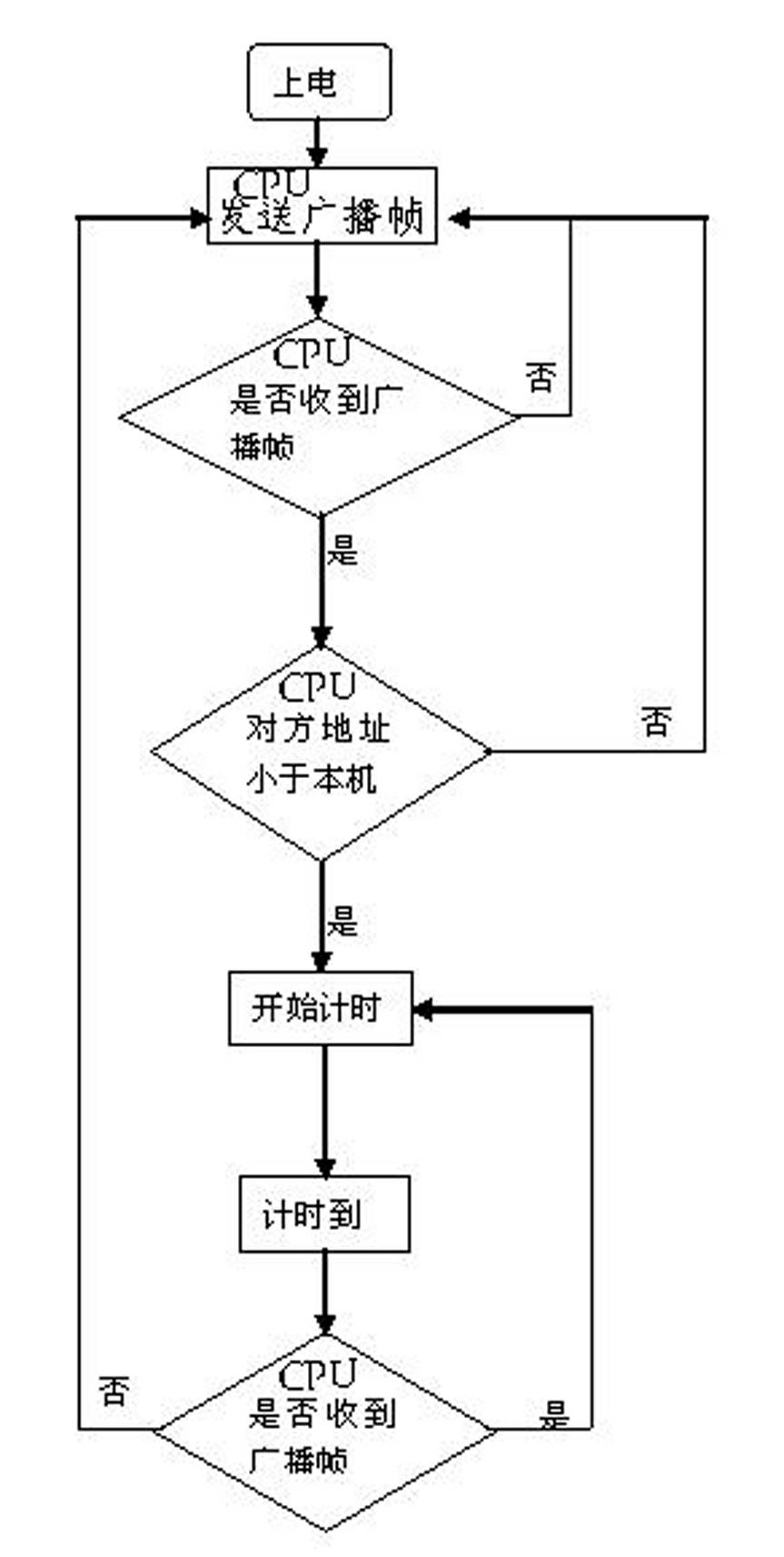

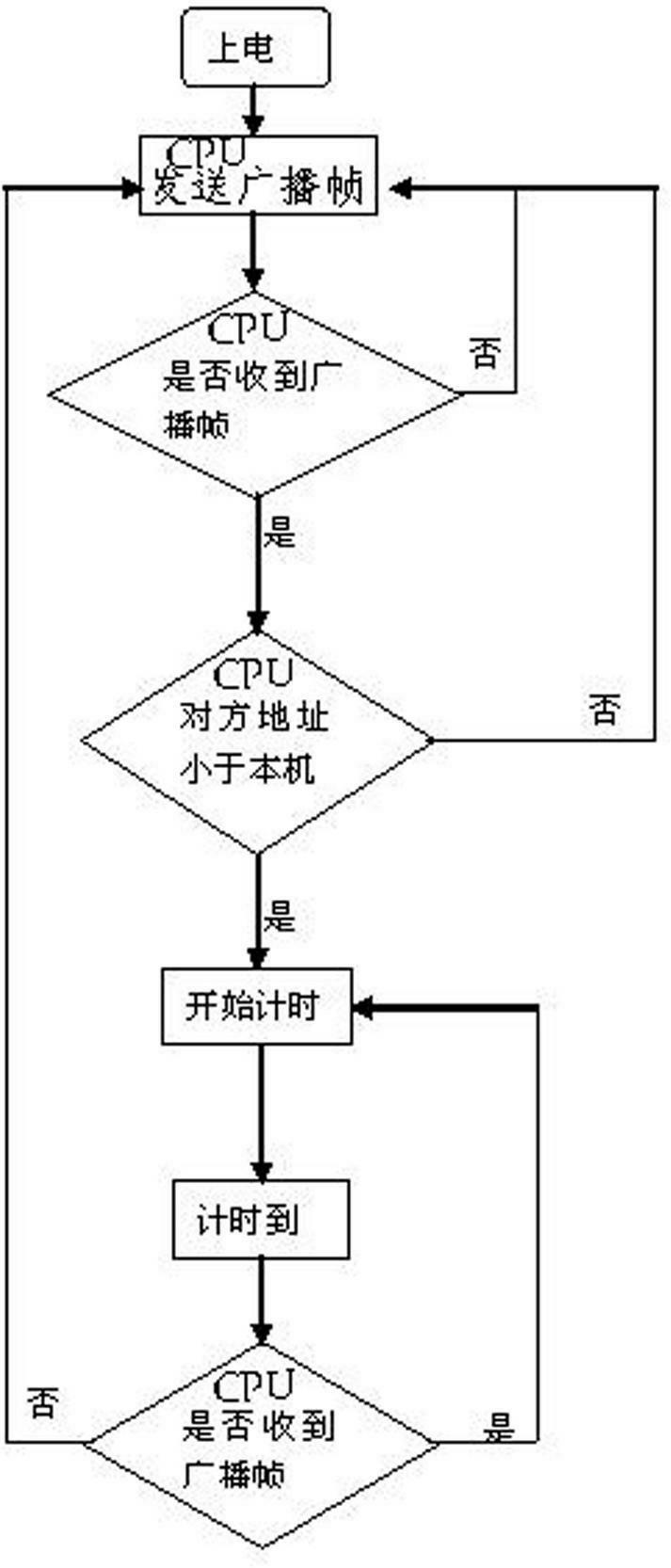

[0016] Such as figure 1 Shown, PLC-based redundant system realization method of the present invention may further comprise the steps:

[0017] First, at least two CPUs with different address codes and at least two I / O modules with different address codes are connected through the CAN bus, that is to say, the data states of all CPUs are automatically synchronized.

[0018] Then start to power on. After power on, each CPU collects data normally, and periodically sends the broadcast frame of the collected data. The principle of priority is adopted, that is, if there are multiple CPUs in the same system, the priority of the module with the smaller address code is higher, as Main CPU; if the CPU receives the broadcast frame of data collected by other CPUs, it compares whether the address of the other party is smaller than the address of the local machine. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com