Manufacturing method of metamaterial antenna housing

A manufacturing method and metamaterial technology, applied in the field of radomes, can solve problems such as process inability to achieve, and achieve the effect of preventing wear and damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

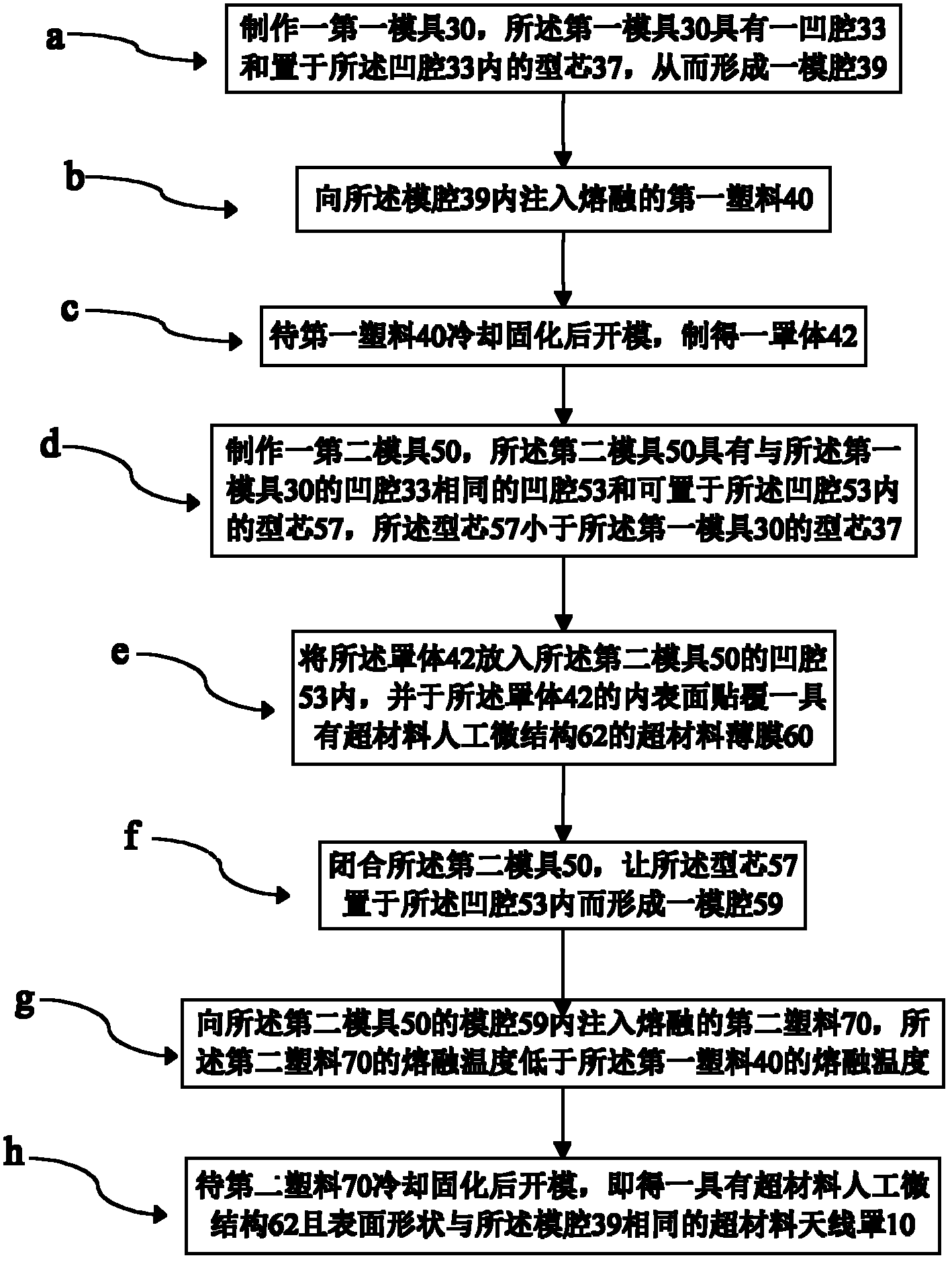

[0031] Such as Figure 1 to Figure 3 Shown is a preferred embodiment of the manufacturing method of the metamaterial radome of the present invention. The preferred embodiment includes the following steps:

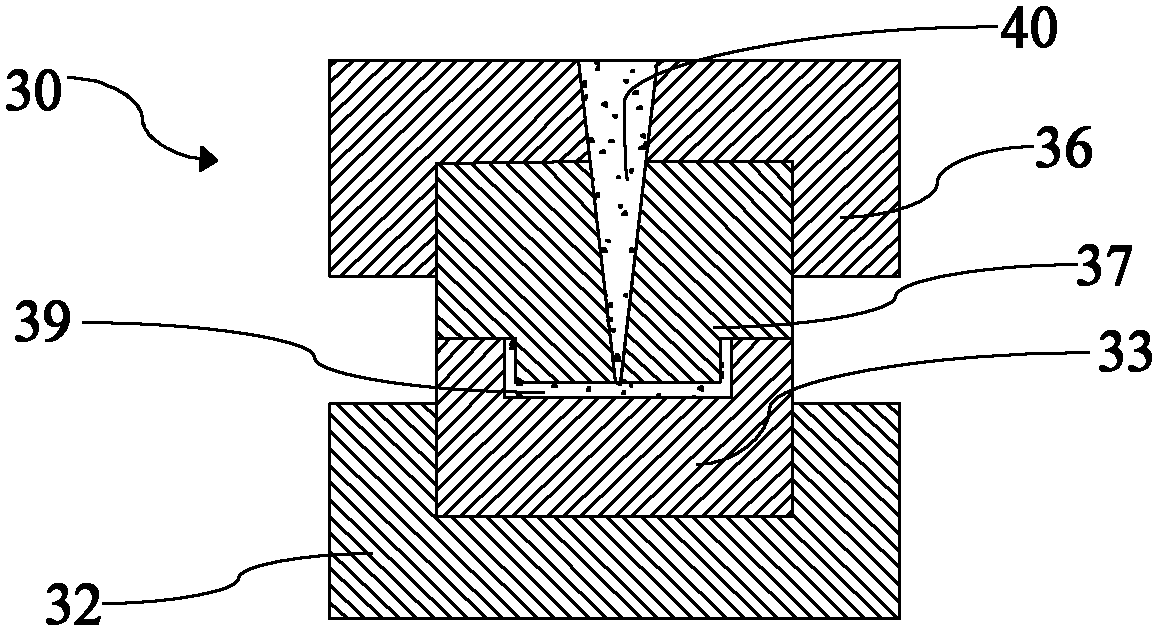

[0032] a. Make a first mold 30 , the first mold 30 has a cavity 33 and a core 37 placed in the cavity 33 , thereby forming a cavity 39 .

[0033] b. Injecting molten first plastic 40 into the mold cavity 39 .

[0034] c. After the first plastic 40 is cooled and solidified, the mold is opened to produce a cover 42 .

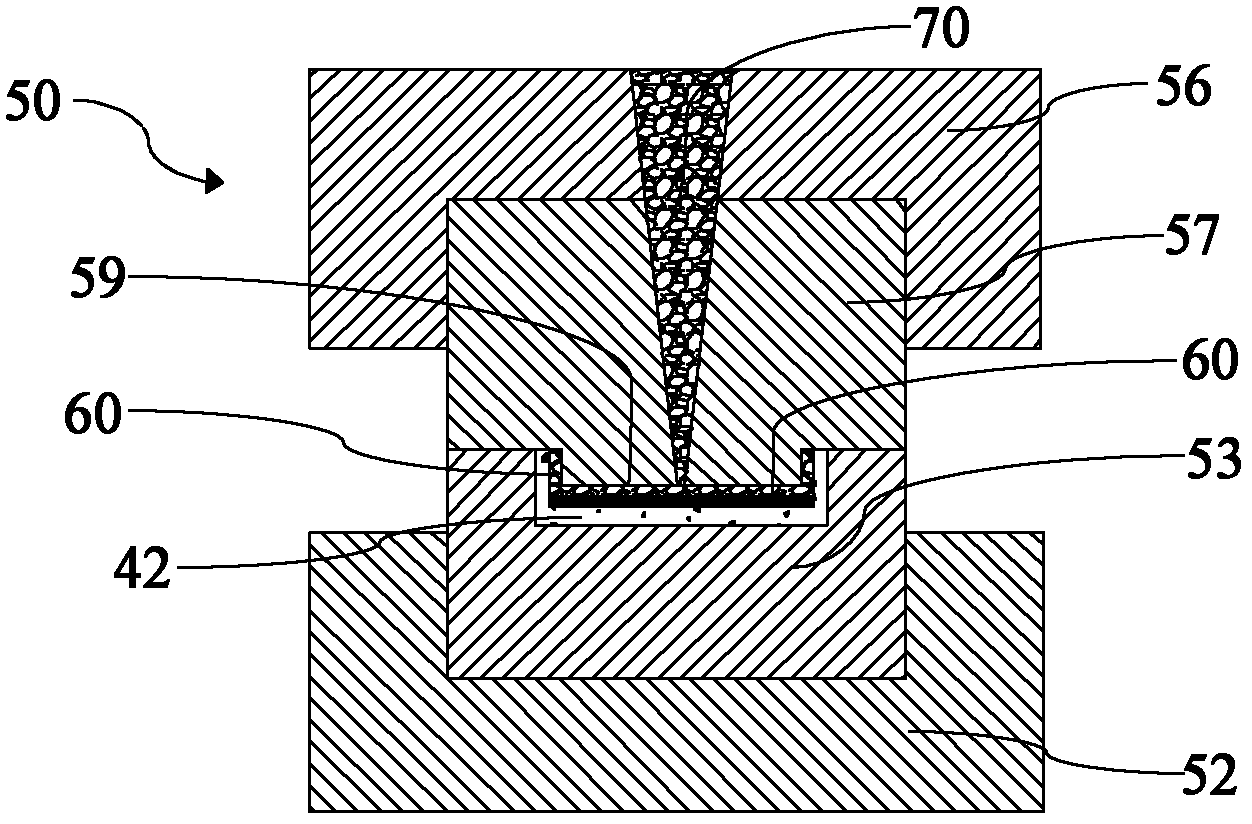

[0035] d, make a second mold 50, the second mold 50 has the same cavity 53 as the cavity 33 of the first mold 30 and a core 57 that can be placed in the cavity 53, the mold The core 57 is smaller than the core 37 of said first mold 30 .

[0036] e. Put the cover body 42 into the concave cavity 53 of the second mold 50 , and paste a metamaterial thin film 60 with a metamaterial artificial microstructure on the inner surface of the cover body 42 .

[0037] f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com