Motor lead wire sheath

A technology for lead-out wires and sheaths, which is applied in the field of motor lead-out wire sheaths, can solve problems such as wear at the bends of the lead-out wires, easy entry of dust and moisture, and gaps, etc., to achieve overall beauty, simple structure, and not easy to wear Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

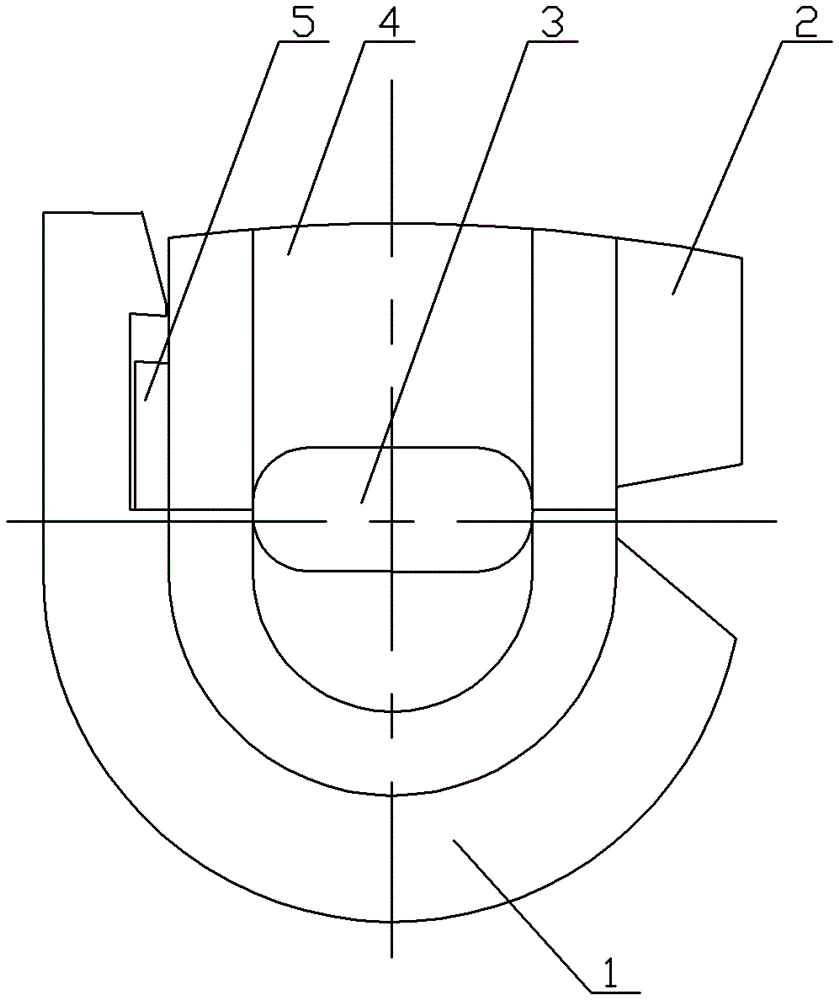

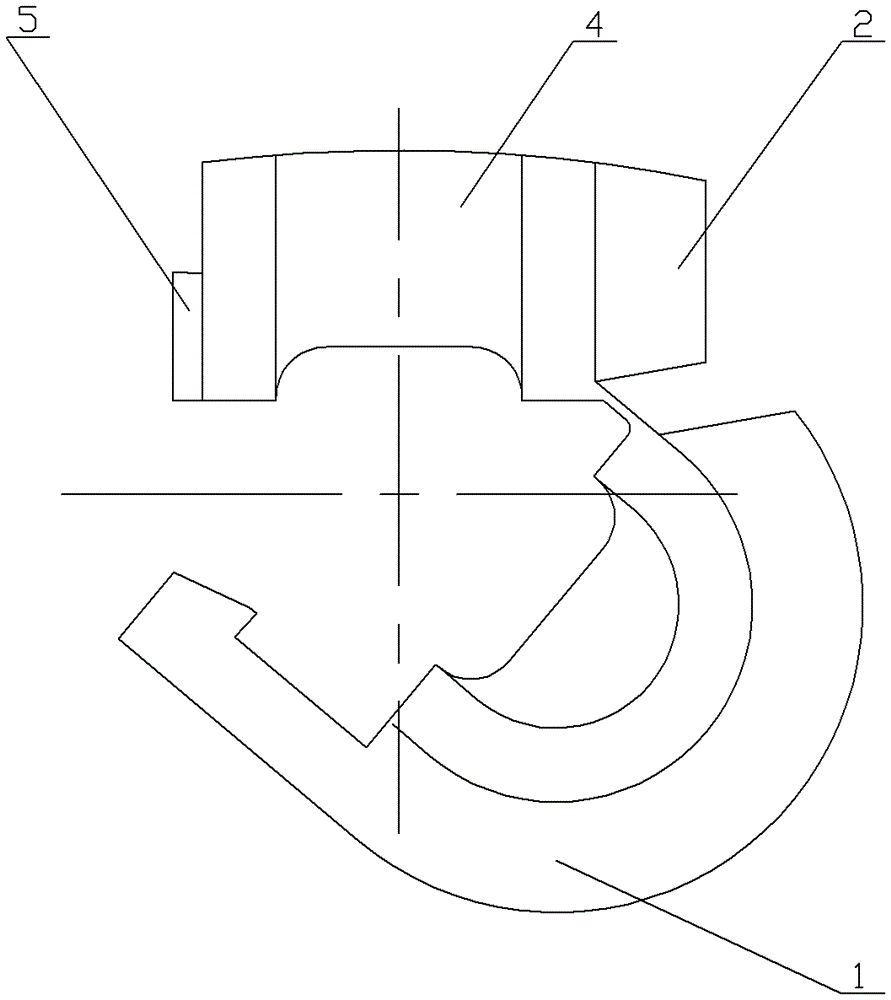

[0014] Please refer to figure 1 and figure 2 as shown, figure 1 It is a structural schematic diagram of the motor lead wire sheath of the present invention; figure 2 It is a structural schematic diagram of the opening state of the motor lead wire sheath of the present invention.

[0015] In this embodiment, a motor lead wire sheath includes a first movable part 2 and a second movable part 1 that are movably connected, and the first movable part 2 and the second movable part 1 are both made of plastic, and The end of the first movable part 2 that is not connected with the second movable part 1 is provided with a bump 5, and the same end of the second movable part 1 and the bump 5 of the first movable part 2 is provided with a groove that matches the bump 5, The middle of the first movable part ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com