Mould capable of forming three-way pipe on one-way pressure machine and forming method thereof

A one-way pressure, three-way technology, used in forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of inability to meet high performance requirements, complex loading process, and high equipment requirements, shortening working time and simplifying the process flow. , the effect of increasing flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

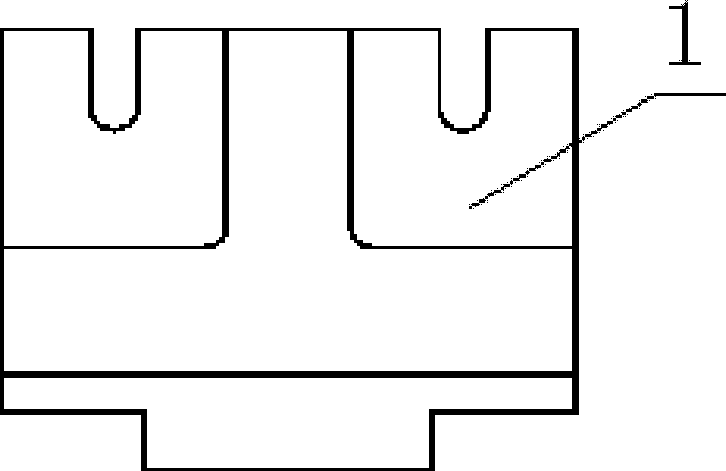

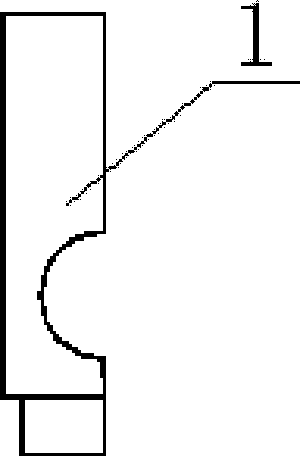

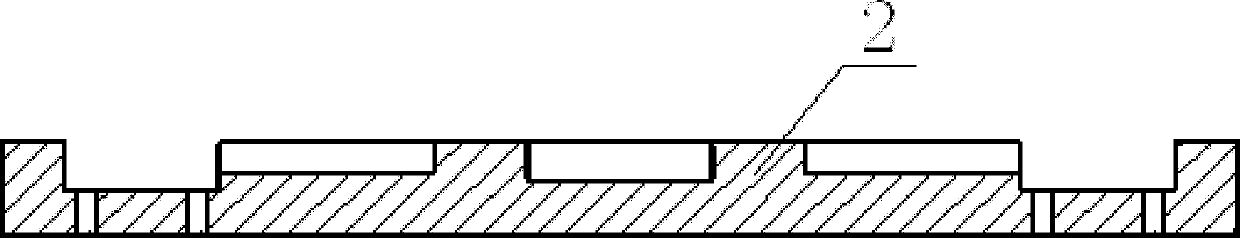

[0040] This embodiment is a mold for forming a three-way piece on a one-way press, including an upper template 8, a lower template 2, 2 dies 1, 2 horizontal punches 3, a vertical punch 7, and 2 sliders 4 , 2 baffle plates 5, 2 oblique wedges 6 and 2 pads 9.

[0041] The two slide blocks 4 are respectively installed in slide block installation grooves located at both ends of the upper surface of the lower template 2 . The horizontal punch 3 is located between the two slide blocks 4 , and the outer end of the horizontal punch 3 cooperates with the inner surface of the slide block 4 . The two baffles 5 are located on the outer sides of the two sliders 4 respectively, and are embedded in the baffle installation grooves on the upper surface of the lower template 2 . The slopes of the two wedges 6 are respectively placed on the slopes of the two sliders 4, and the dovetail blocks on the side surfaces of each wedge 6 are inserted into the dovetail grooves on the side surface of the ...

Embodiment 2

[0052] This embodiment is a method for forming a three-way piece using the mold for forming a three-way piece on a one-way press described in the first embodiment. In the tee mold used in this embodiment, the slope angles α of the wedge and the slide block are both 45°, and the height of the block is 130 mm.

[0053] The raw material of the tee formed in this embodiment is 7075 aluminum alloy extruded bar, the mold material is AISI-H21 steel, and the formed tee includes branch pipes and main pipes. Such as Figure 9 As shown, L is the height of the branch pipe, h is the depth of the branch pipe, H is the depth of one side of the main pipe, and 0.5H<h<H, D1 is the inner diameter of the main pipe, D2 is the outer diameter of the main pipe, the inner diameter of the branch pipe of the tee and the main pipe The diameters are correspondingly equal. In this embodiment, h=48mm, H=66mm, L=70mm, D1=32mm, D2=66mm.

[0054] In the forming process of this embodiment, the main tube of t...

Embodiment 3

[0065] This embodiment is a method for forming a three-way piece using the mold for forming a three-way piece on a one-way press described in the first embodiment. In the tee mold used in this embodiment, the slope angles α of the wedge and the slide block are both 45°, and the height of the block is 130 mm.

[0066] The raw material of the tee formed in this embodiment is 7050 aluminum alloy extruded bar, the mold material is AISI-H21 steel, and the formed tee includes branch pipes and main pipes. Such as Figure 9 As shown, L is the height of the branch pipe, h is the depth of the branch pipe, H is the depth of one side of the main pipe, and 0.5H<h<H, D1 is the inner diameter of the main pipe, D2 is the outer diameter of the main pipe, the inner diameter of the branch pipe of the tee and the main pipe The diameters are correspondingly equal. In this embodiment, h=48mm, H=66mm, L=70mm, D1=32mm, D2=66mm.

[0067] In the forming process of this embodiment, the main tube of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com