Manufacturing facility of slow springback polyether polyurethane sponge

A technology of polyurethane sponge and slow rebound polyether, which is applied in the direction of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., and can solve the problem of soft polyurethane sponge slow rebound polyether type polyurethane sponge manufacturing equipment, etc. problems, to achieve the effect of saving reaction raw materials and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

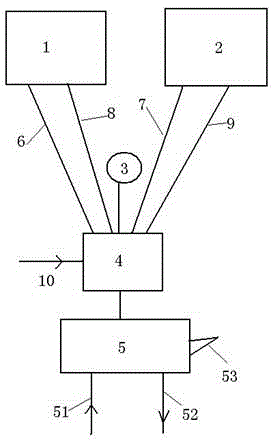

[0024] The manufacturing equipment of the slow rebound polyether type polyurethane sponge includes a raw material tank, a foaming mold 5, a computer control device 3 and a feeding gun 4, and the raw material tank includes a first raw material tank 1 and a second raw material tank 2, and the first raw material tank 1 The first feeding pipe 6 is connected with the inlet of the feeding gun 4, the second feeding pipe 7 is connected between the second raw material tank 2 and the inlet of the feeding gun 4, the feeding gun 4 and the computer control device 3 Connected, the outlet of feeding gun 4 is connected with foam mold 5.

Embodiment 2

[0026] Such as figure 1 Shown, the manufacturing equipment of slow resilience polyether type polyurethane sponge comprises raw material tank, foaming mold 5, computer control device 3 and feeding gun 4, raw material tank comprises first raw material tank 1 and second raw material tank 2, the first raw material tank The first feeding pipe 6 is connected between the raw material tank 1 and the inlet of the feeding gun 4, the first return pipe 8 is connected between the first raw material tank 1 and the inlet of the feeding gun 4, the second raw material tank 2 and the feeding A second feeding pipe 7 is connected between the inlets of the material guns 4 , and a second return pipe 9 is connected between the second raw material tank 2 and the inlets of the feeding guns 4 .

[0027] The feeding gun 4 is connected with the computer control device 3 , and the outlet of the feeding gun 4 is connected with the foaming mold 5 . Foaming mold 5 is made up of mold cover and mold seat, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com