Low-resistance fairing of corrugate sheath

A technology of fairing and corrugated sleeve is applied in the field of low-resistance fairing of corrugated sleeve to achieve the effects of suppressing airflow separation, strong operability and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings.

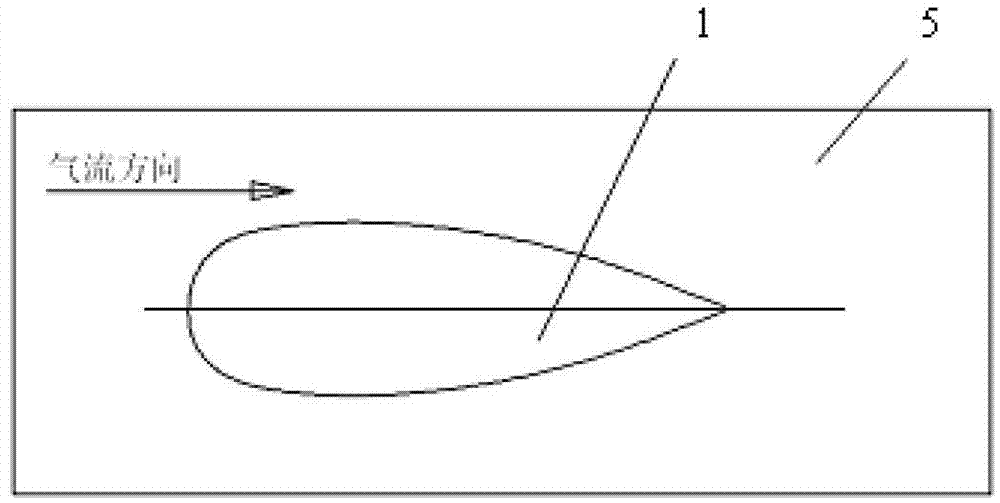

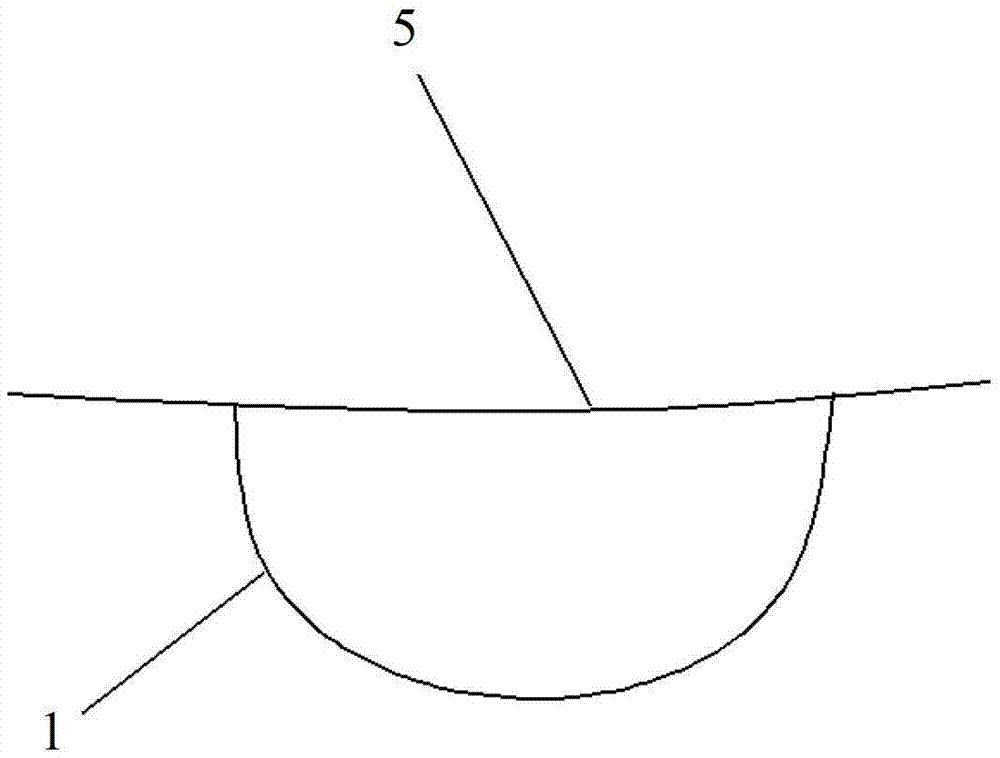

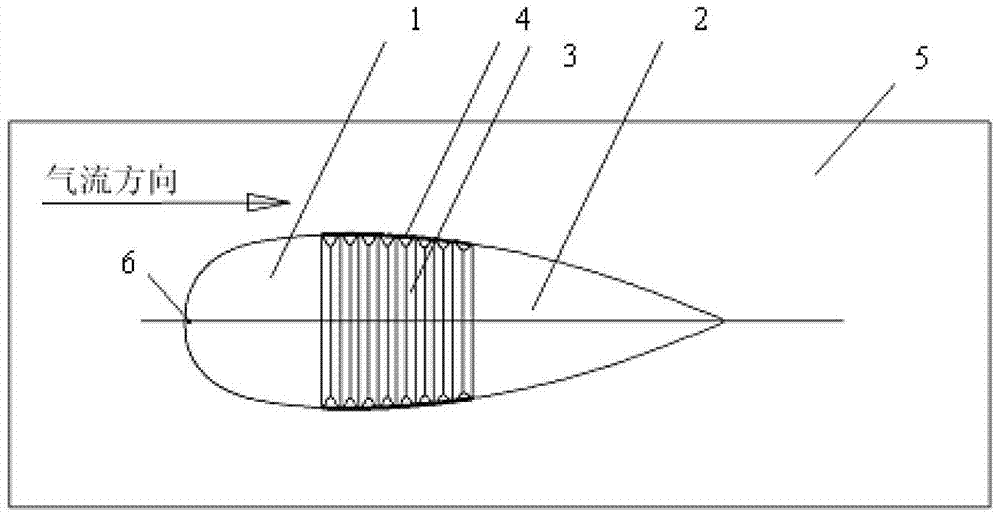

[0016] Described fairing is made up of fairing head 1, fairing rear part 2, fairing corrugated cover 3, surface elastic rubber 4, body surface 5, through hole 6. The fairing head 1 is fixedly riveted or bonded on the aircraft body surface 5, and a through hole 6 is left near the front end of the fairing head 1, that is, the stagnation point of the airflow, and the through hole communicates with the fairing inner cavity. The front end of the fairing bellows 3 is bonded to the rear end surface of the fairing head 1, the rear end of the fairing bellows [3] is connected with the fairing rear 2, and the fairing bellows 3 has good flexibility in the longitudinal direction , with good support stiffness in other directions. The surface elastic rubber 4 is bonded on the outside of the corrugated sleeve, and the bonding position is the peak position of the corrugated sleeve. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com