Strengthened cyclone single-barrel straight-through type air filter for desert

A straight-through, air filter technology, used in fuel air filters, climate change adaptation, machines/engines, etc., can solve the problems of complex structure, reduced air intake, inconvenient maintenance, etc., and achieve high pre-filtering efficiency, The effect of small air intake resistance and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

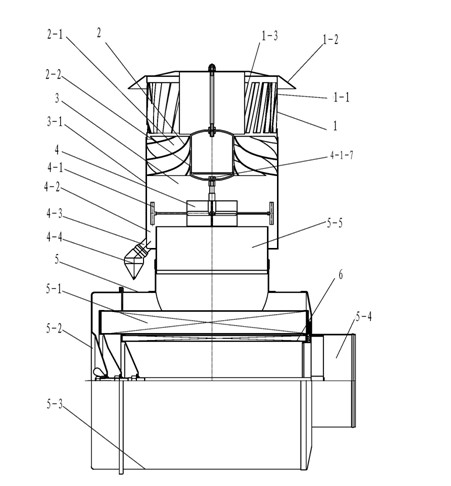

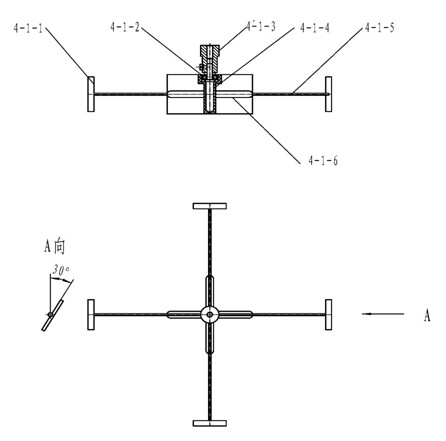

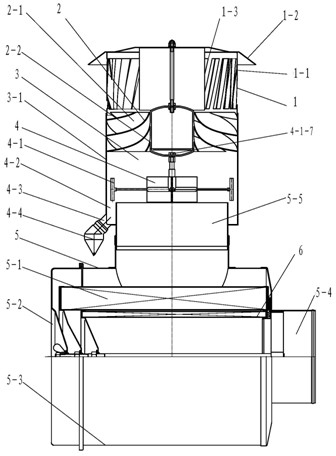

[0017] Embodiment 1, see attached figure 1 , attached figure 2 , Enhanced cyclone single-tube straight-through desert air filter includes louvered tangential air intake device (1), air intake swirler (2), air / ash separation chamber (3), automatic ash discharge system (4), and main Filter (5), and safety filter core (6), the above parts are arranged in order from top to bottom.

[0018] The louver type tangential air intake device (1) has an angle of 30° between the tangential air intake port and the axis of the filter so that the tangentially entering air is in a downward swirling state. In the center of the tangential air intake device, A guide cylinder (1-3) is provided, and a rainproof cover (1-2) is provided on the top of the tangential air intake device.

[0019] The number of guide vanes and the installation angle of the guide vanes of the air inlet swirler (2) are determined by optimizing the design according to the difference with the rated flow of the matched engin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com