High-position air inlet pipe assembly with axial swirling pipe

An axial swirl, intake pipe technology, used in fuel air filters, combustion air/combustion-air treatment, engine components, etc., can solve the problem of high resistance in the intake system, increase engine fuel consumption, and pre-filter efficiency. low problems, to achieve the effect of improving fuel rate and fuel consumption, improving pre-filtration efficiency, and reducing original resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

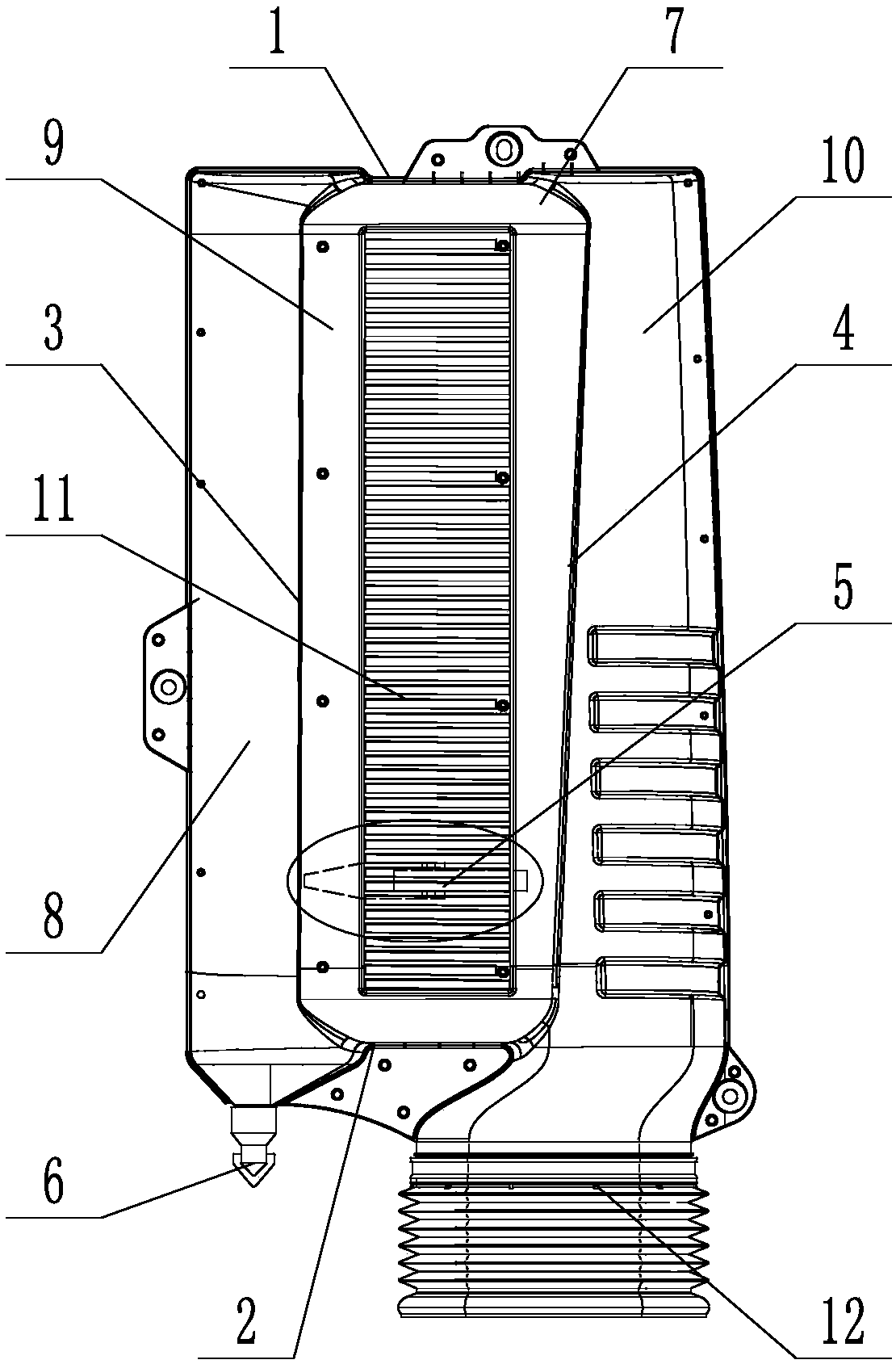

[0015] Such as figure 1 with 2 As shown, the present invention includes an upper casing 1, a lower casing 2, a first partition 3, a second partition 4, an axial swirl pipe 5 and a dust discharge valve 6, and the upper casing 1 and the lower casing 2 are welded together, the inside of the upper shell 1 and the lower shell 2 form a cavity 7, and the first partition 3 and the second partition 4 are sequentially installed in the cavity 7 from left to right, so The first partition 3 and the second partition 4 divide the cavity 7 from left to right into a dust discharge chamber 8, an air inlet chamber 9 and an air outlet chamber 10, and the axial swirl pipe 5 is installed near the inlet The bottom position of the cavity 9, the outer side of the bottom of the dust discharge cavity 8 is located on the lower casing 2 and a dust discharge valve 6 is installed;

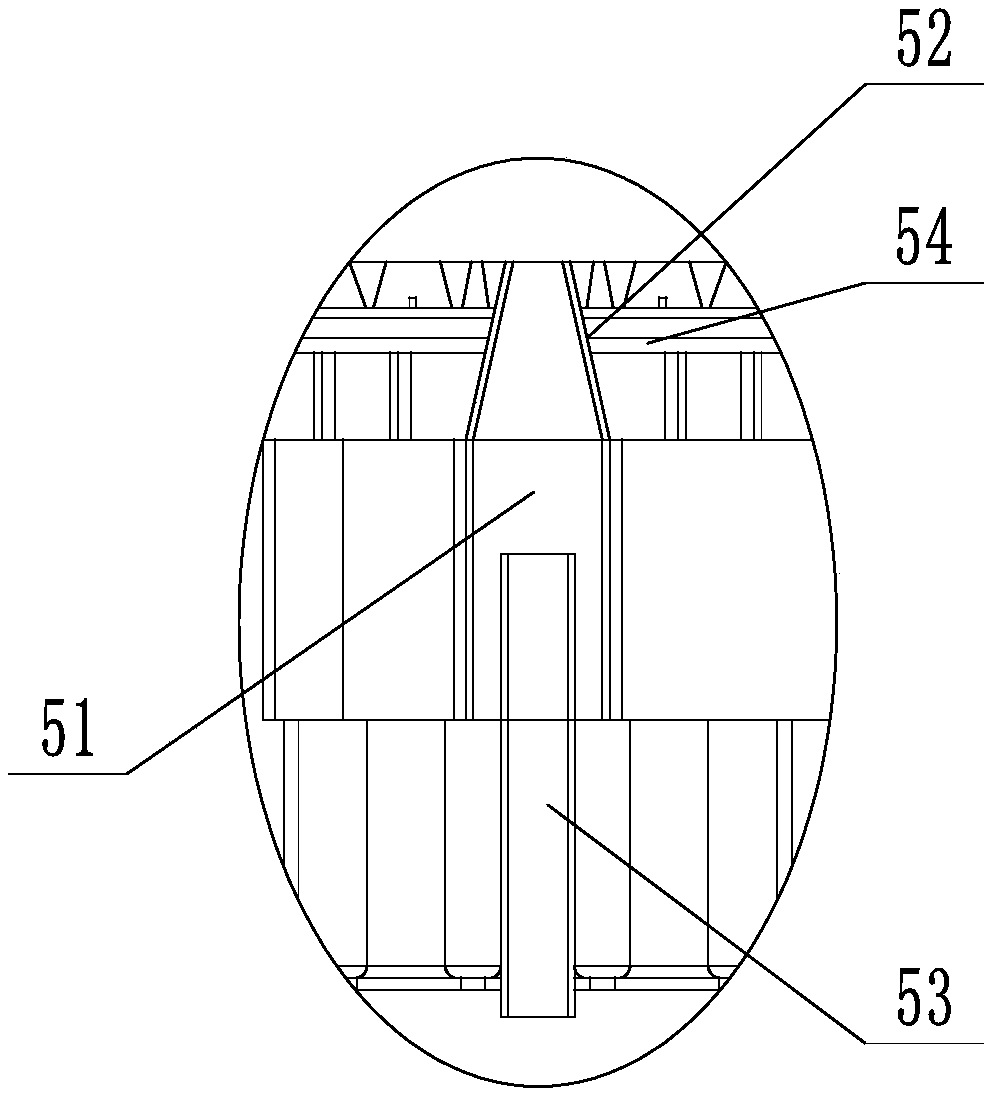

[0016] The axial swirl tube 5 includes a central tube 51, a blade ring 52 and a swirl tube 53, the bottom of the central tub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com