Hydraulic drive mechanism of heliostat

A driving mechanism and heliostat technology, applied in solar collector controllers, solar thermal devices, lighting and heating equipment, etc., can solve the problems of high gear processing cost, high maintenance cost, easy wear of gears, etc. Design, uniform and smooth movement, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

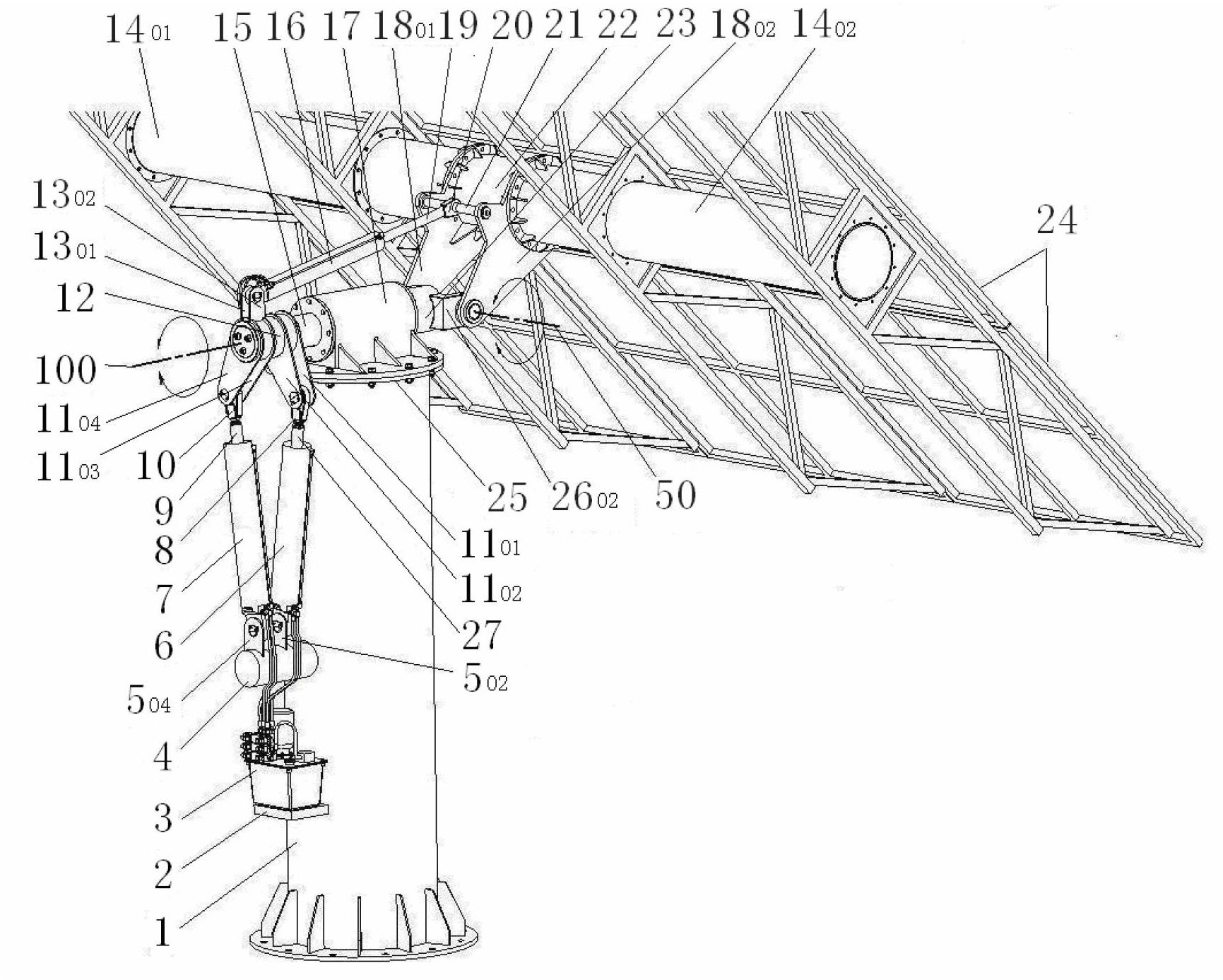

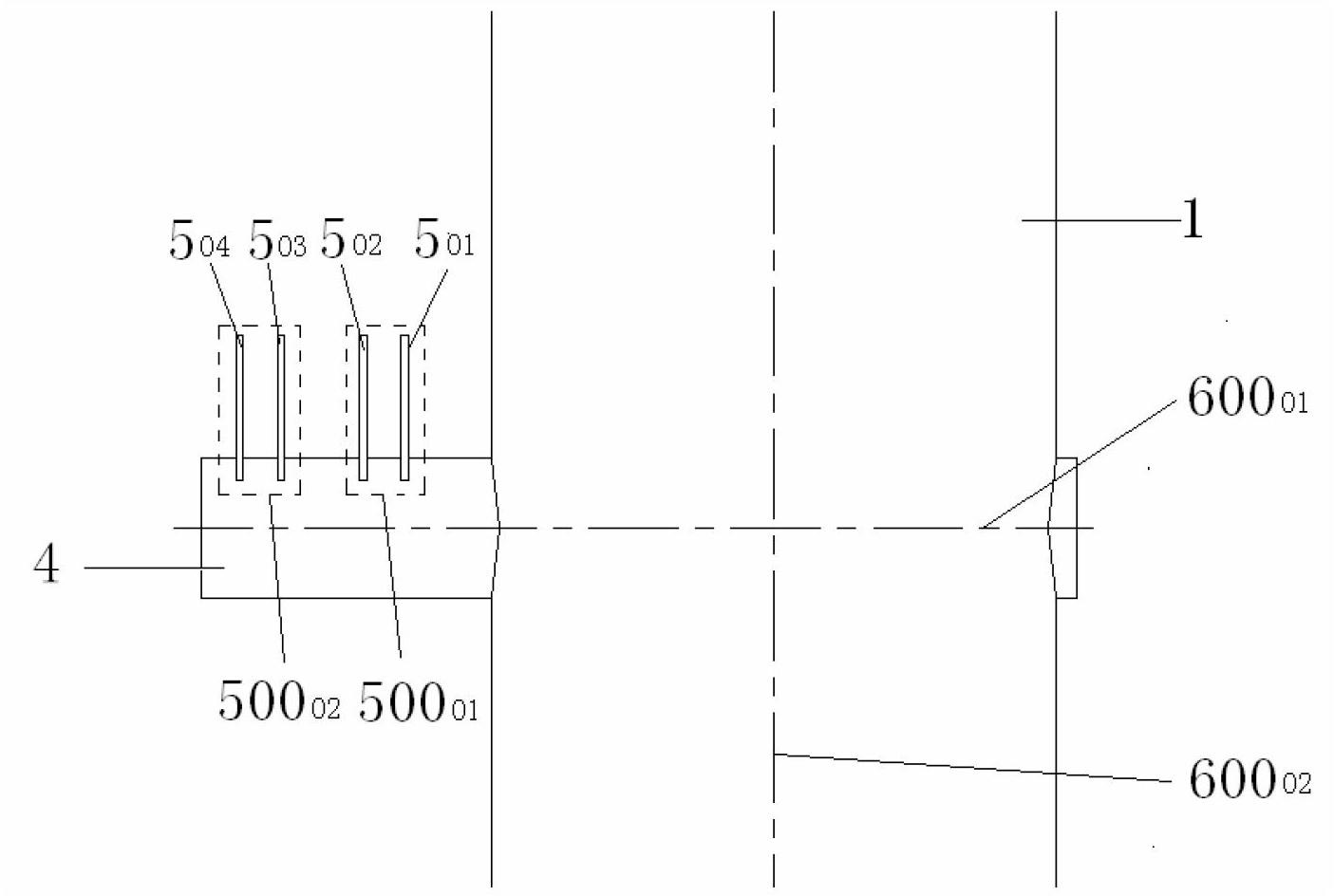

[0041] Such as figure 1 As shown, the heliostat column 1 is welded with a support beam 4 . Such as figure 2 As shown, the support beam axis 600 01 With heliostat column axis 600 02 Intersect perpendicularly. A first support plate 5 is welded along the length direction of the support beam 4 on the support beam 4 01 , the second support plate 5 02 , the third support plate 5 03 , the fourth support plate 5 04 , four support plates 5 01 、5 02 、5 03 、5 04 600 perpendicular to the support beam axis 01 ; the first support plate 5 01 and the second support plate 5 02 For the first set of support plates 500 01 , the third support plate 5 03 and the fourth support plate 5 04 For the second set of support plates 500 02 .

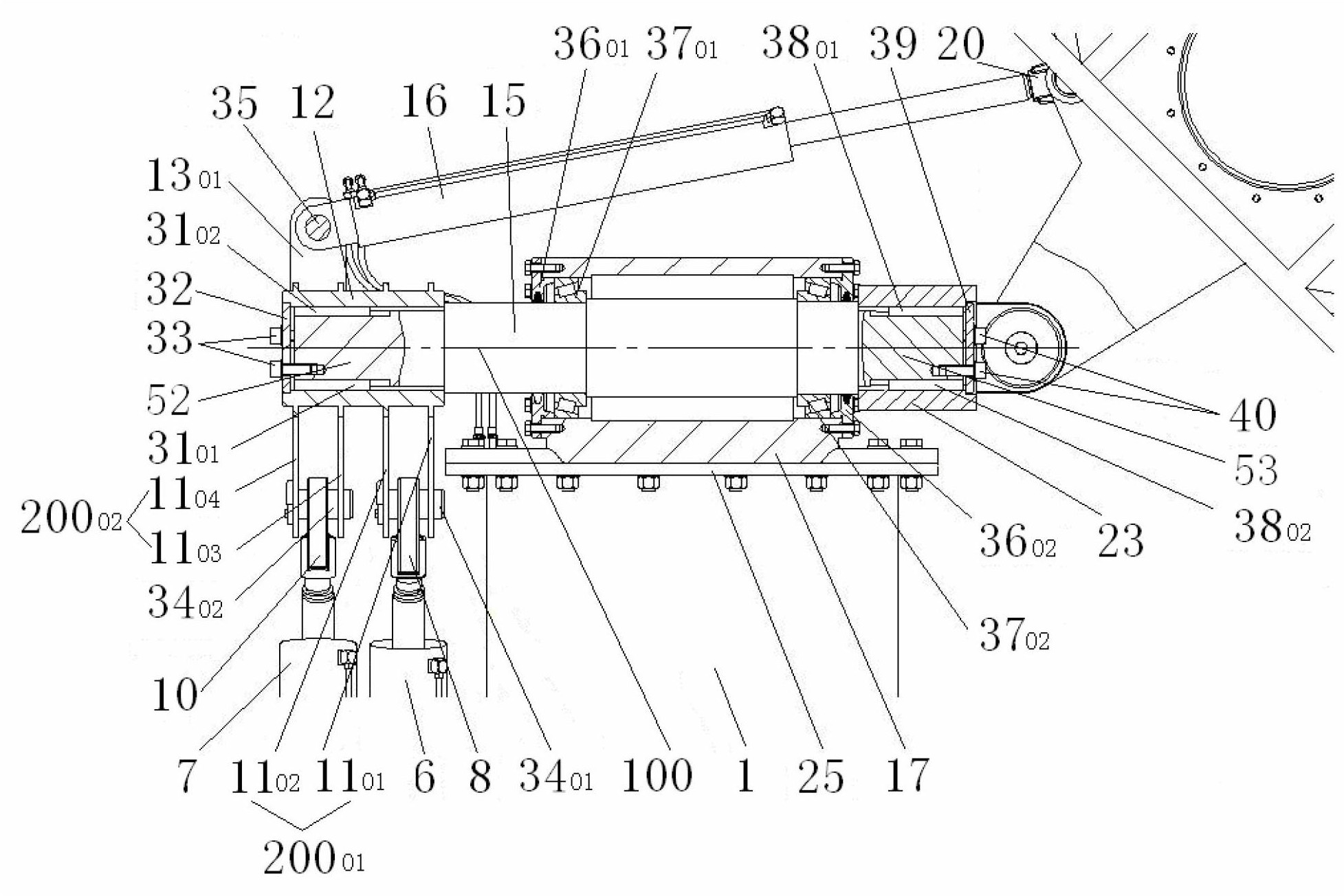

[0042] Such as figure 1 and image 3 As shown, the upper part of the heliostat column 1 is welded with a column flange 25 , and the upper part of the column flange 25 is fixedly connected with a support 17 . Such as image 3 As shown, the horizo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com