Rail pressing type water seal ring cold machine

A water-sealed and annular cooler technology, which is applied in the direction of processing discharged materials, furnaces, lighting and heating equipment, etc., can solve the problems of high energy consumption and large dust, achieve good sealing performance, continuous sealing, and save equipment investment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

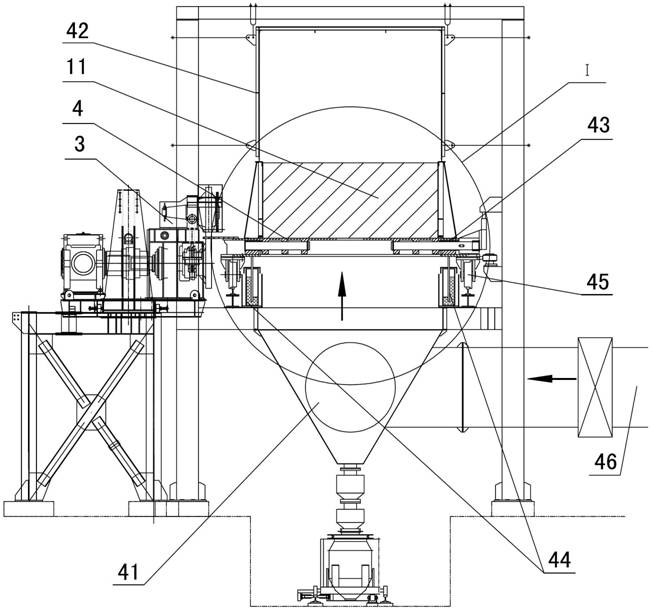

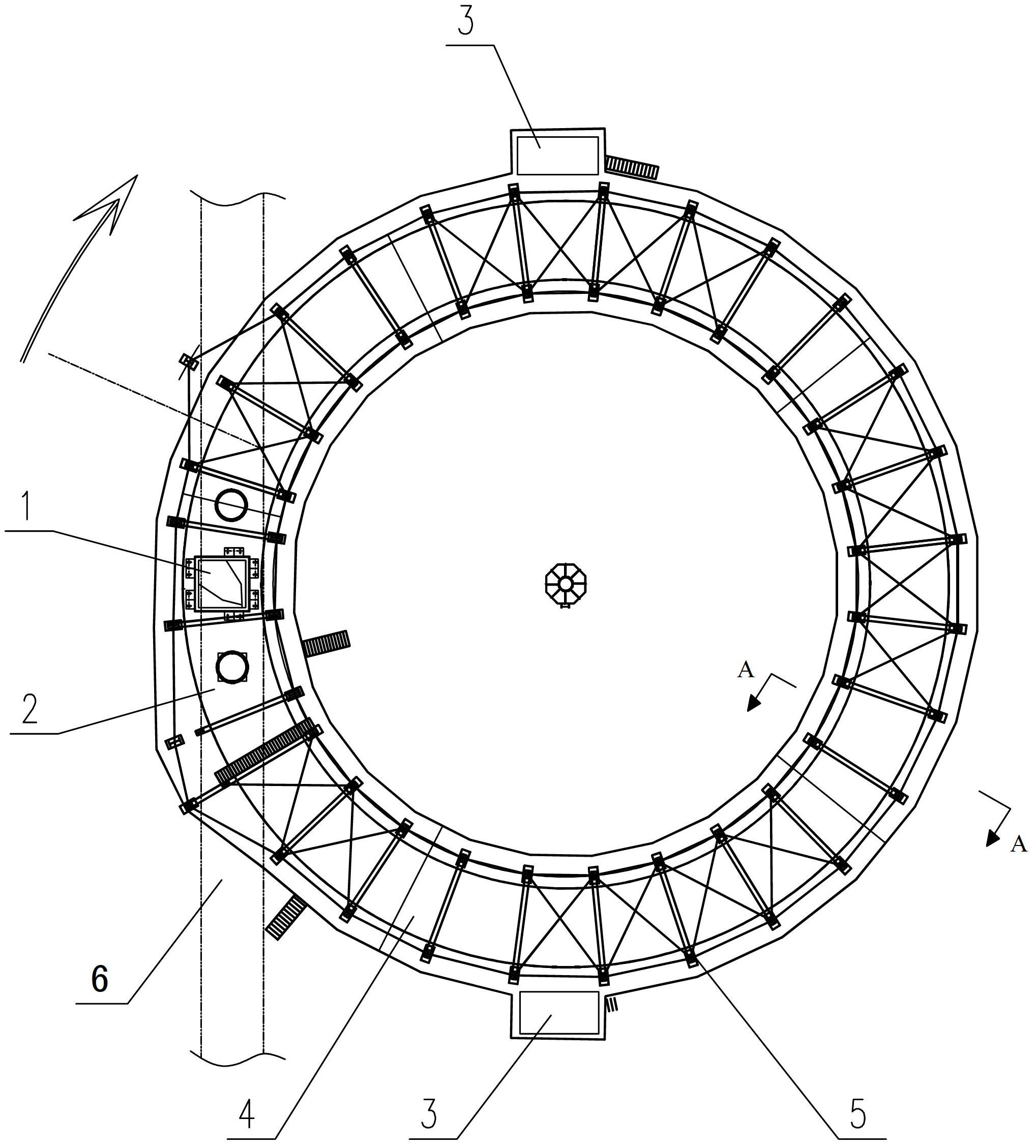

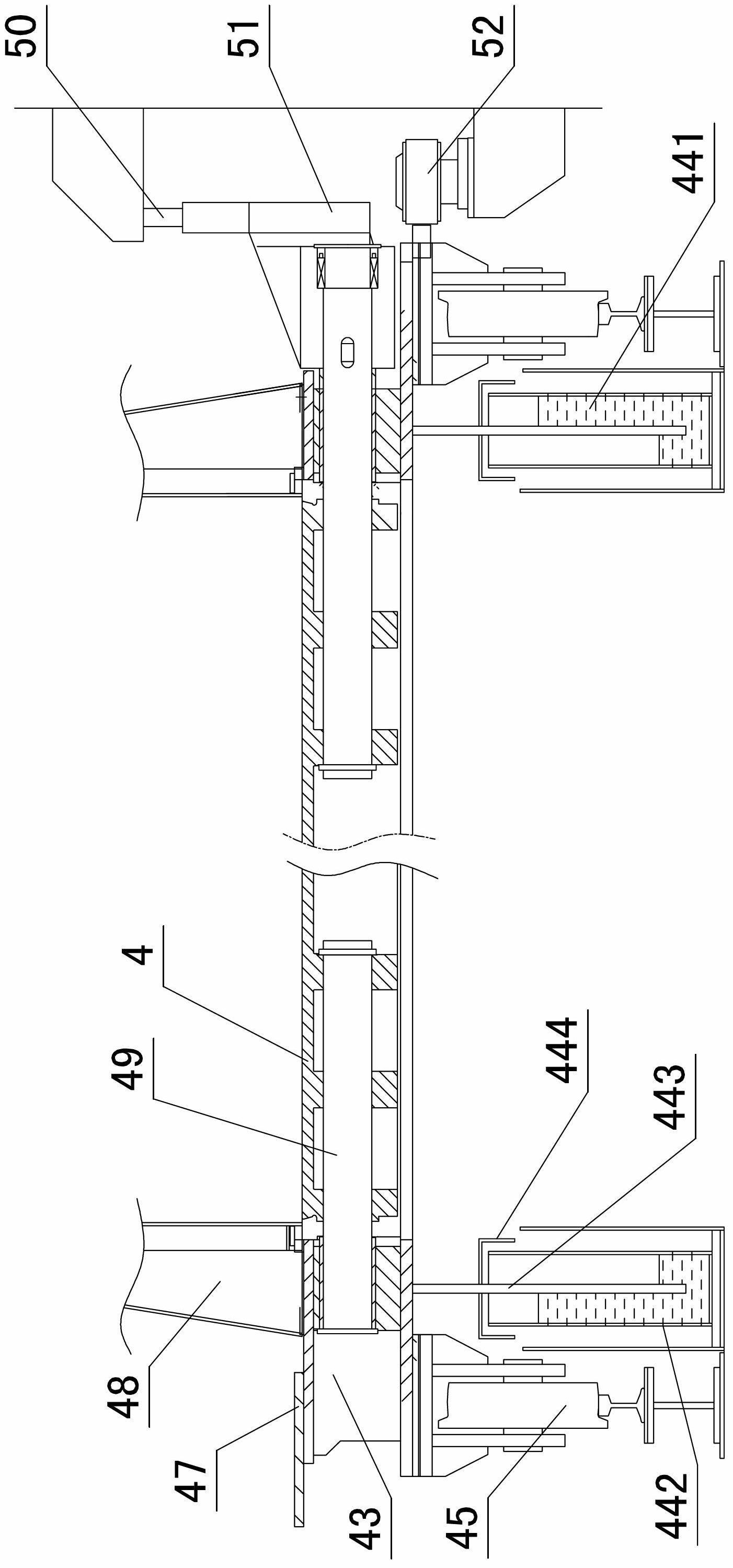

[0019] The rail-pressing type water-sealed annular cooler of the present invention mainly includes a driving device, a rotary unit, an air intake unit, a support unit, a trolley unit and a water-sealed unit.

[0020] Such as figure 1 As shown, the hot sintered ore enters the ore feeding chute 1 after being crushed by a single roll crusher, and then is continuously and evenly distributed to the grate plate of the trolley body 4 by the ore feeding chute 1. The trolley body 4 is driven by the driving device 3 and carries the hot sintered ore and rotates clockwise around the center of the ring cooler to reach the unloading hopper 2, and pours the sintered ore that has been cooled to the required temperature into the ore unloading hopper 2 to complete cooling and unloading. material work. The unloaded sintered ore is carried by the finished pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com