Stretch forming machine for direct-current armature lap winding

A technology of stacked windings and direct current, applied in the direction of electric components, manufacturing motor generators, electrical components, etc., can solve the problems of time-consuming and laborious, difficult to ensure the consistency of coil shape, etc., to achieve reliable performance, good consistency, and high production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

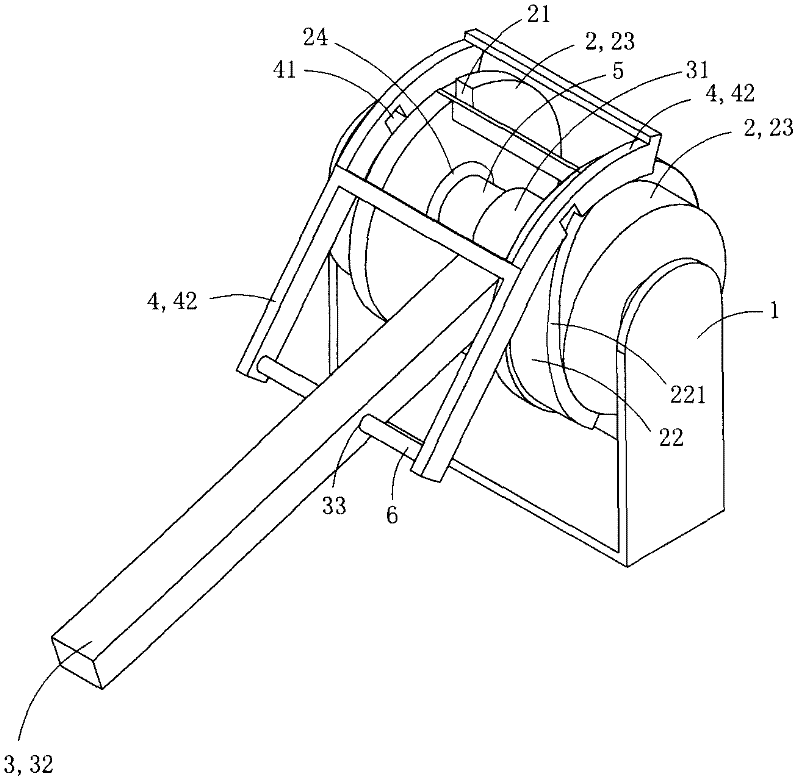

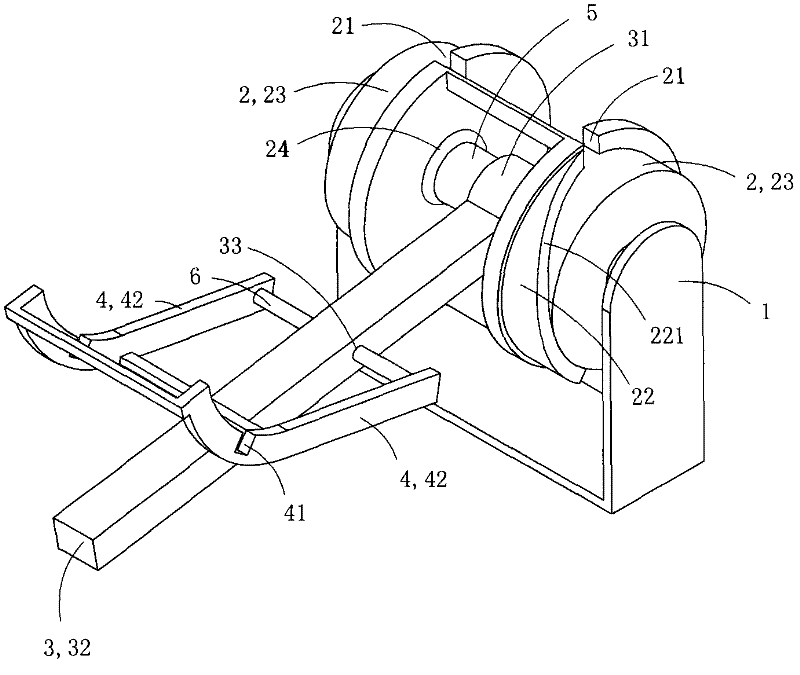

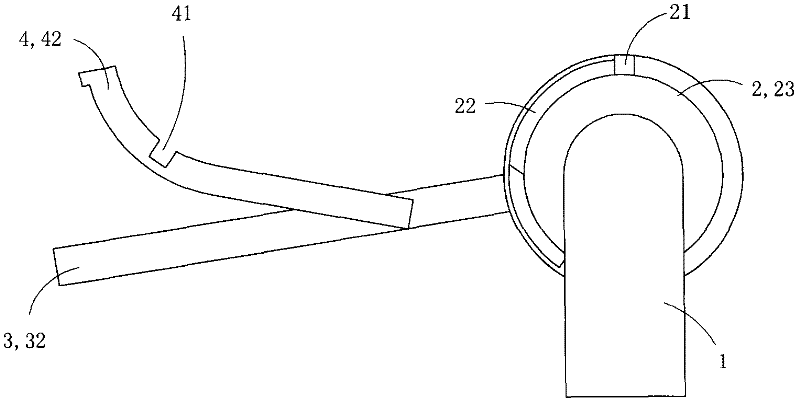

[0020] Figure 1 to Figure 3 A specific embodiment of the invention is shown in which figure 1 It is a schematic diagram of a three-dimensional structure of the present invention; figure 2 for figure 1 A schematic diagram of the three-dimensional structure of the crimping part in the open state of the DC armature stacked winding stretch forming machine shown; image 3 for figure 1 A side view of the DC armature stacked winding stretch forming machine.

[0021] This embodiment is a DC armature stacked winding stretch forming machine, see Figure 1 to Figure 3 , including a base 1, a limit piece 2 fixedly arranged on the base 1 for limiting one side of the coil, a pull rod 3 rotatably arranged on the base 1, and a pull rod 3 rotatably arranged on the pull rod 3 for pulling the coil on the other side The crimping part 4 on one side; the limiter 2 is provided with a limit card slot 21 for clamping one side of the coil and two guide rails 22 for guiding the extension directio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com