Shuttle pushing mechanism of small-cam circular weaving machine

A circular loom and small cam technology, which is applied to circular looms, looms, textiles, etc., can solve the problems of increased energy consumption, high noise, and large resistance, and can reduce energy consumption, noise, and reverse. The effect of resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

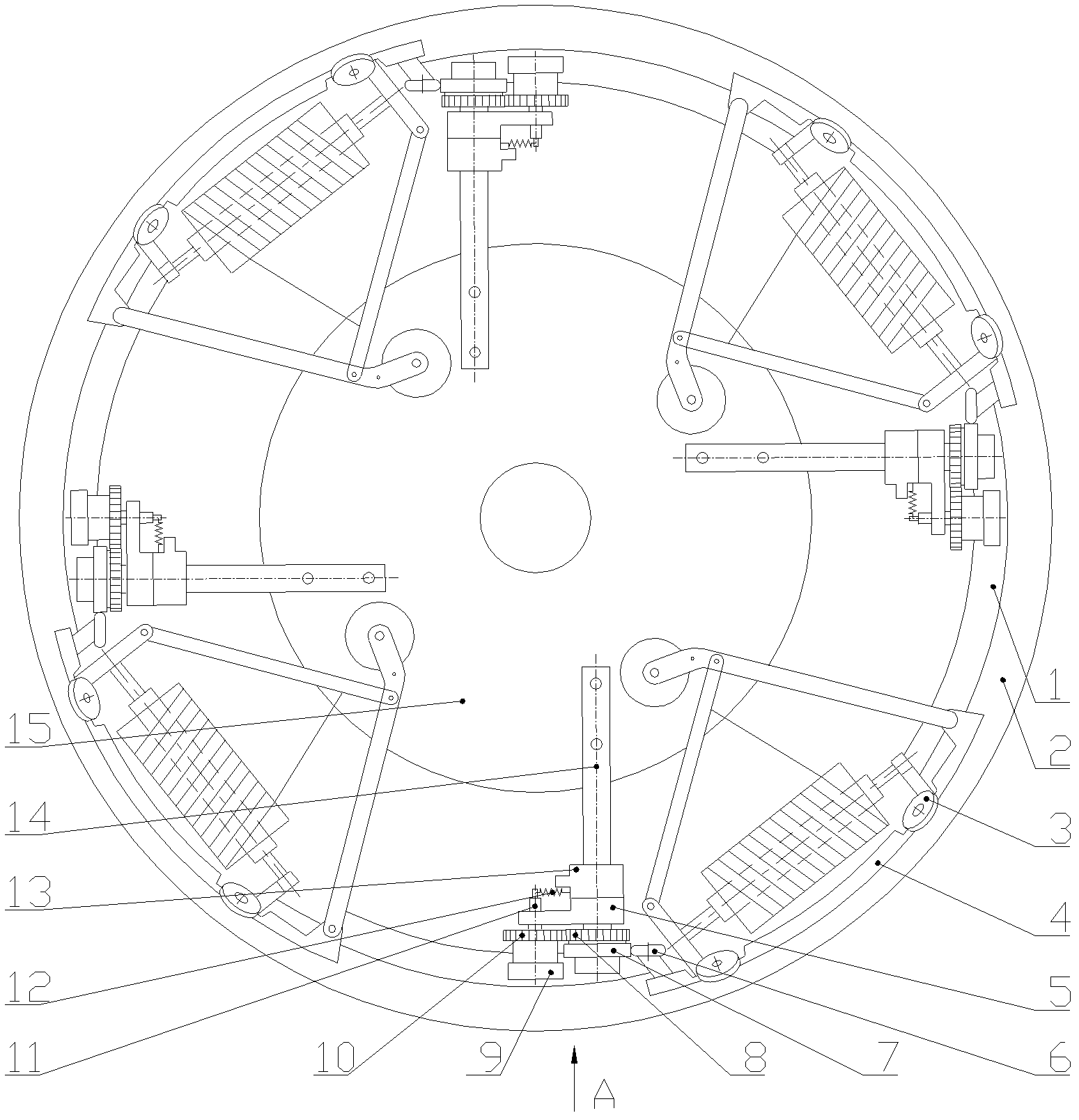

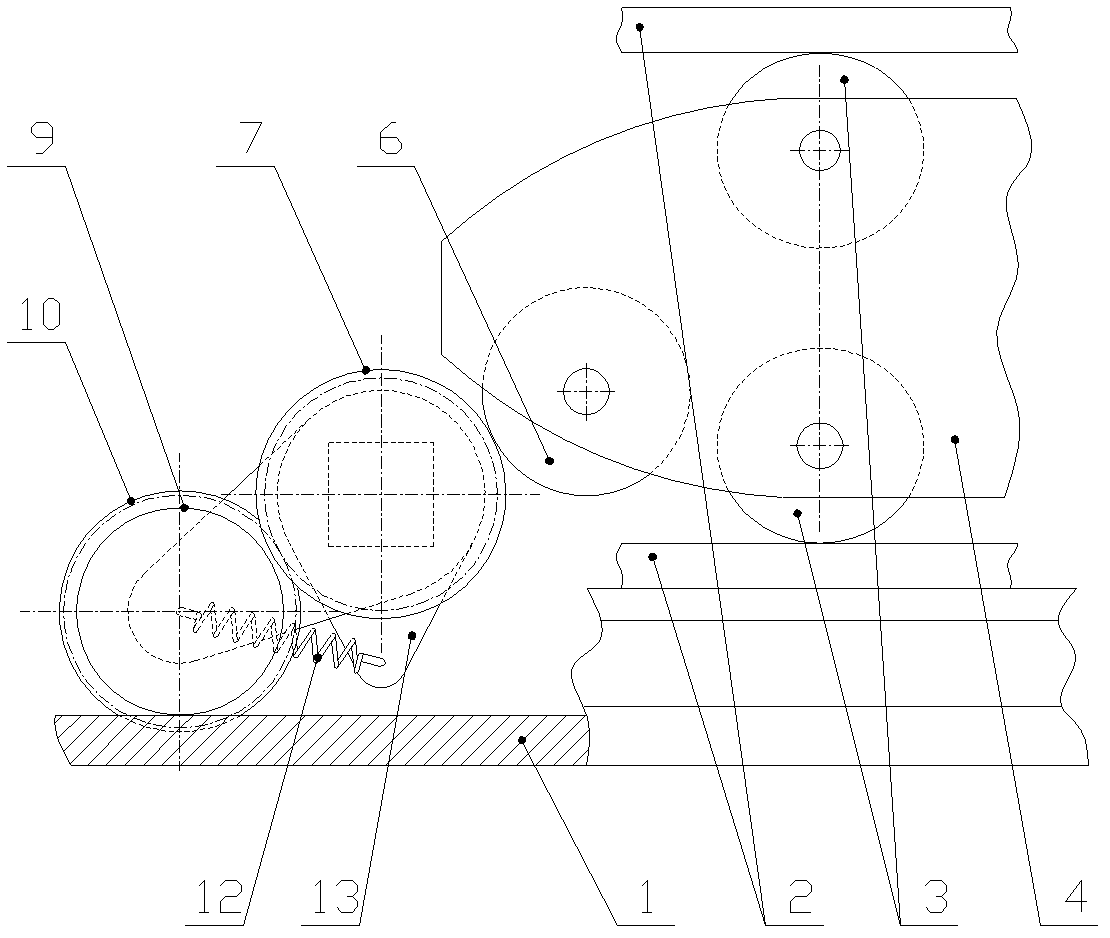

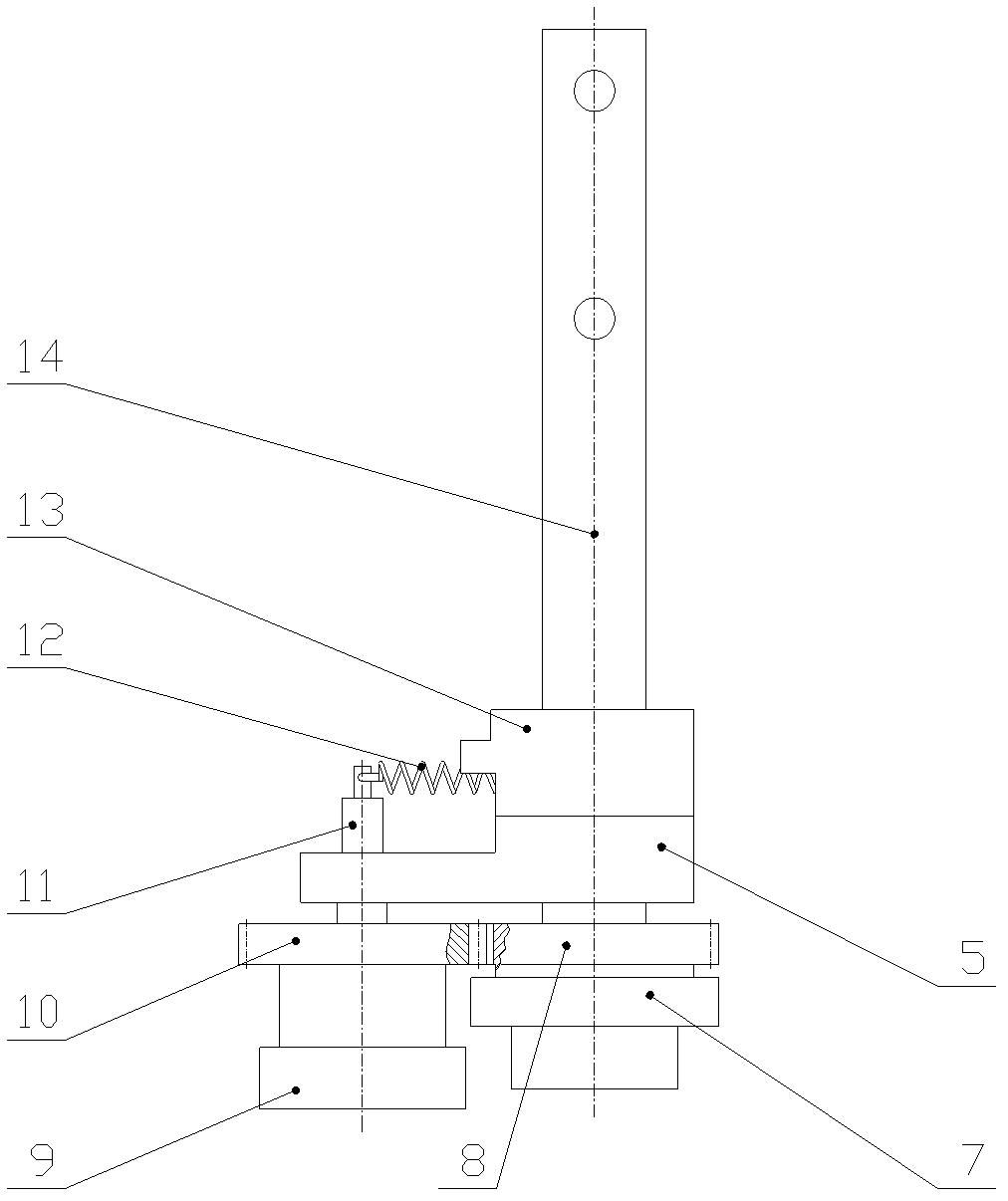

[0014] Such as Figure 1 to Figure 3 Shown is the embodiment of the push shuttle mechanism of the small cam circular loom of the present invention,

[0015] refer to figure 1 , figure 2 and image 3 , 1-friction wheel track, 2-shuttle track, 3-shuttle wheel, 4-shuttle, 5-friction wheel bracket, 6-shuttle tail wheel, 7-propelling wheel, 8-passive gear, 9-friction wheel, 10- Driving gear, 11-friction wheel mandrel, 12-spring, 13-spring seat, 14-propelling arm, 15-propelling disc.

[0016] The propulsion arm 14 that is fixed on the propulsion disc 15 is connected with the propulsion wheel 7 in rotation, and the front of the propulsion wheel 7 is in rolling contact with the shuttle tail wheel 6, and the friction wheel 9 is arranged on the rear lower side position of the propulsion wheel 7, and is fixed on the friction wheel. The driving gear 10 on the 9 meshes with the driven gear 8 fixed on the propulsion wheel 7, the friction wheel 9 is connected in rotation with the fricti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com