Lubricating device with electromagnetic quantity control mechanism for rotary kiln wheel shaft

A technology of a quantity control mechanism and a lubricating device, which is applied in the field of rotary kilns, can solve the problems of poor lubricating oil use effect, difficult control of lubricating oil delivery amount, and poor lubricating effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

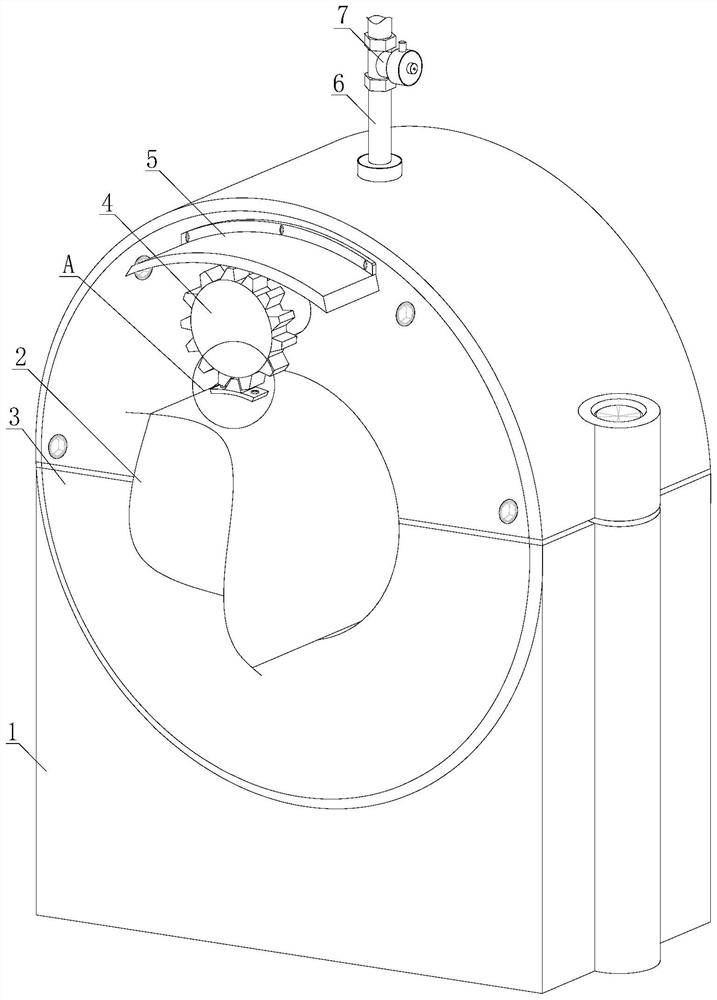

[0030] see figure 1 , the rotary kiln wheel shaft is equipped with a lubrication device with an electromagnetic control mechanism, including a support seat 1, a wheel shaft 2, a wheel shaft seat 3, an oiling mechanism 4, a protective cover 5, a connecting pipe 6 and a solenoid valve 7, and the wheel shaft seat 3 is installed on the support seat 1, the axle 2 is inserted into the middle of the axle seat 3, the oiling mechanism 4 is located at the upper end of the axle 2 and runs through the axle seat 3, the protective cover 5 is installed on the upper side of the outer end of the oiling mechanism 4 on the axle seat 3, and the connection pipe 6 The lower end is communicated with the middle part of the upper end of the axle seat 3, the upper end of the connecting pipe 6 is connected with the solenoid valve 7, and the other end of the solenoid valve 7 is connected with the hydraulic pump and the lubricating oil tank in turn.

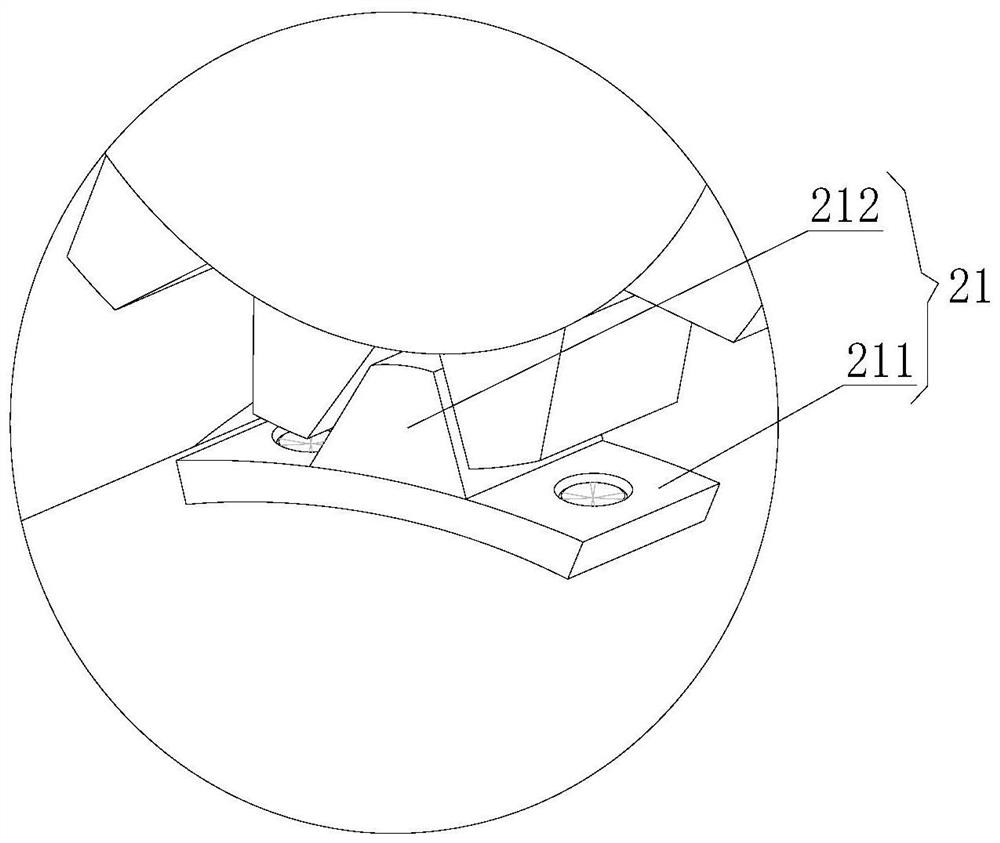

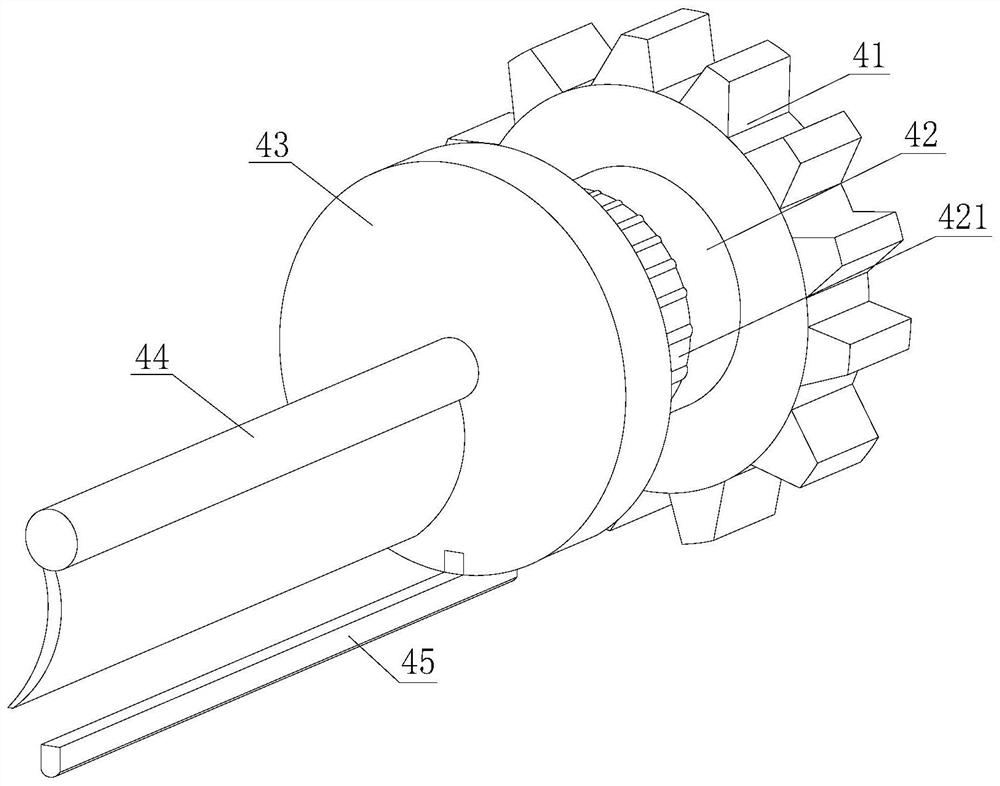

[0031] see Figure 2-3, the rotary kiln wheel shaft u...

Embodiment 2

[0038] see figure 1 , the rotary kiln wheel shaft is equipped with a lubrication device with an electromagnetic control mechanism, including a support seat 1, a wheel shaft 2, a wheel shaft seat 3, an oiling mechanism 4, a protective cover 5, a connecting pipe 6 and a solenoid valve 7, and the wheel shaft seat 3 is installed on the support seat 1, the axle 2 is inserted into the middle of the axle seat 3, the oiling mechanism 4 is located at the upper end of the axle 2 and runs through the axle seat 3, the protective cover 5 is installed on the upper side of the outer end of the oiling mechanism 4 on the axle seat 3, and the connection pipe 6 The lower end is communicated with the middle part of the upper end of the axle seat 3, the upper end of the connecting pipe 6 is connected with the solenoid valve 7, and the other end of the solenoid valve 7 is connected with the hydraulic pump and the lubricating oil tank in turn.

[0039] see Figure 2-3 , the rotary kiln wheel shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com