Transformer and driving device adopting same

A driving device and transformer technology, applied in the direction of transformers, transformer/inductor components, transformer/inductor coils/windings/connections, etc., can solve problems that hinder the compactness of products or devices, and increase manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Various specific examples of the present invention are given below, and these examples are only used to describe the specific implementation of the present invention in detail, and should not be construed as limiting the present invention.

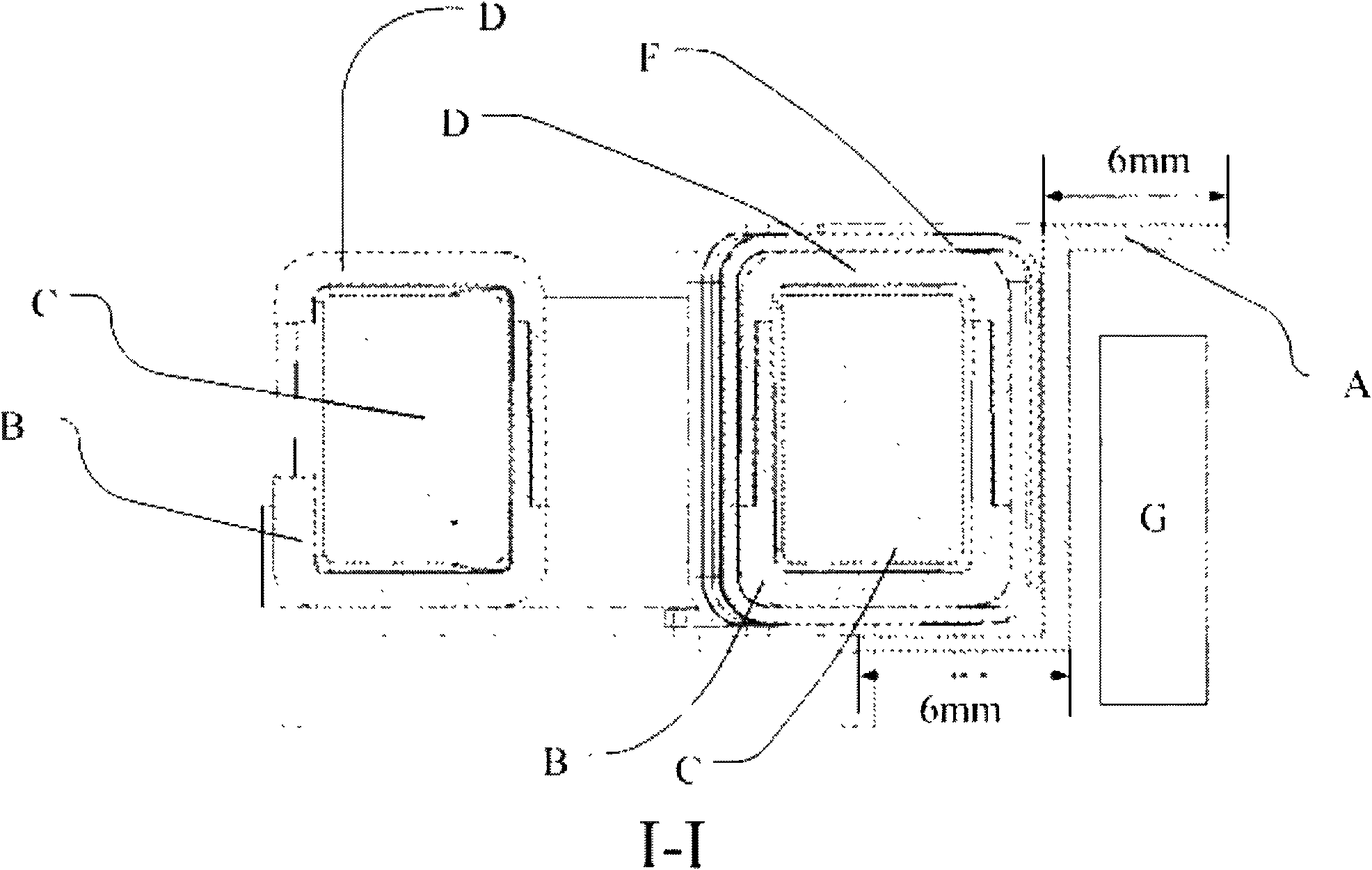

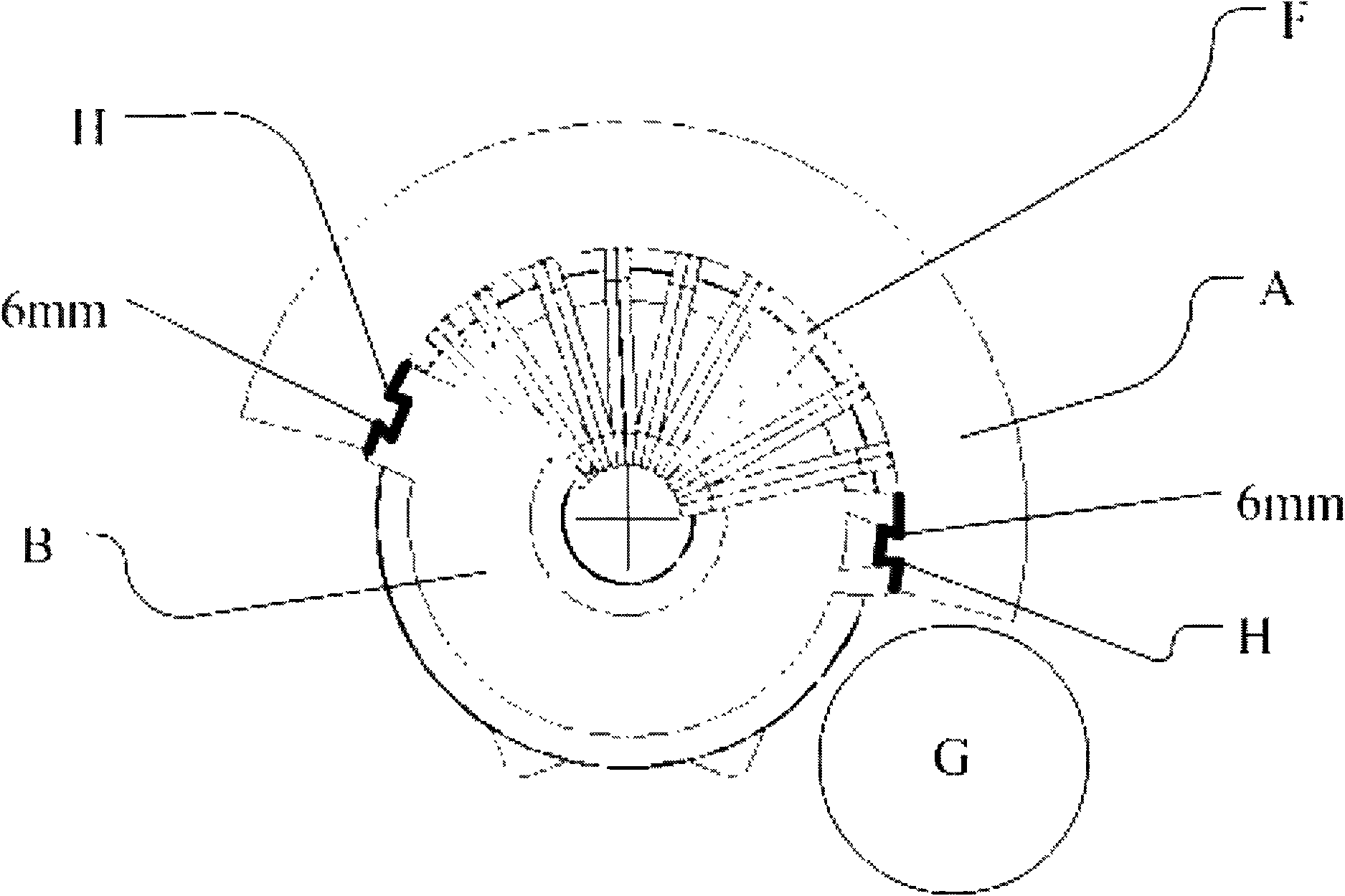

[0025] According to an embodiment of the present invention, a transformer is provided, which includes: a magnetic core; a bobbin; at least one winding wound on the bobbin; and an insulating spacer unit coupled with the bobbin, which is configured to separate the winding from the outside of the transformer At least meet the predetermined electrical isolation standards between other conductive parts.

[0026] Embodiments of the present invention will be described in detail below through specific examples.

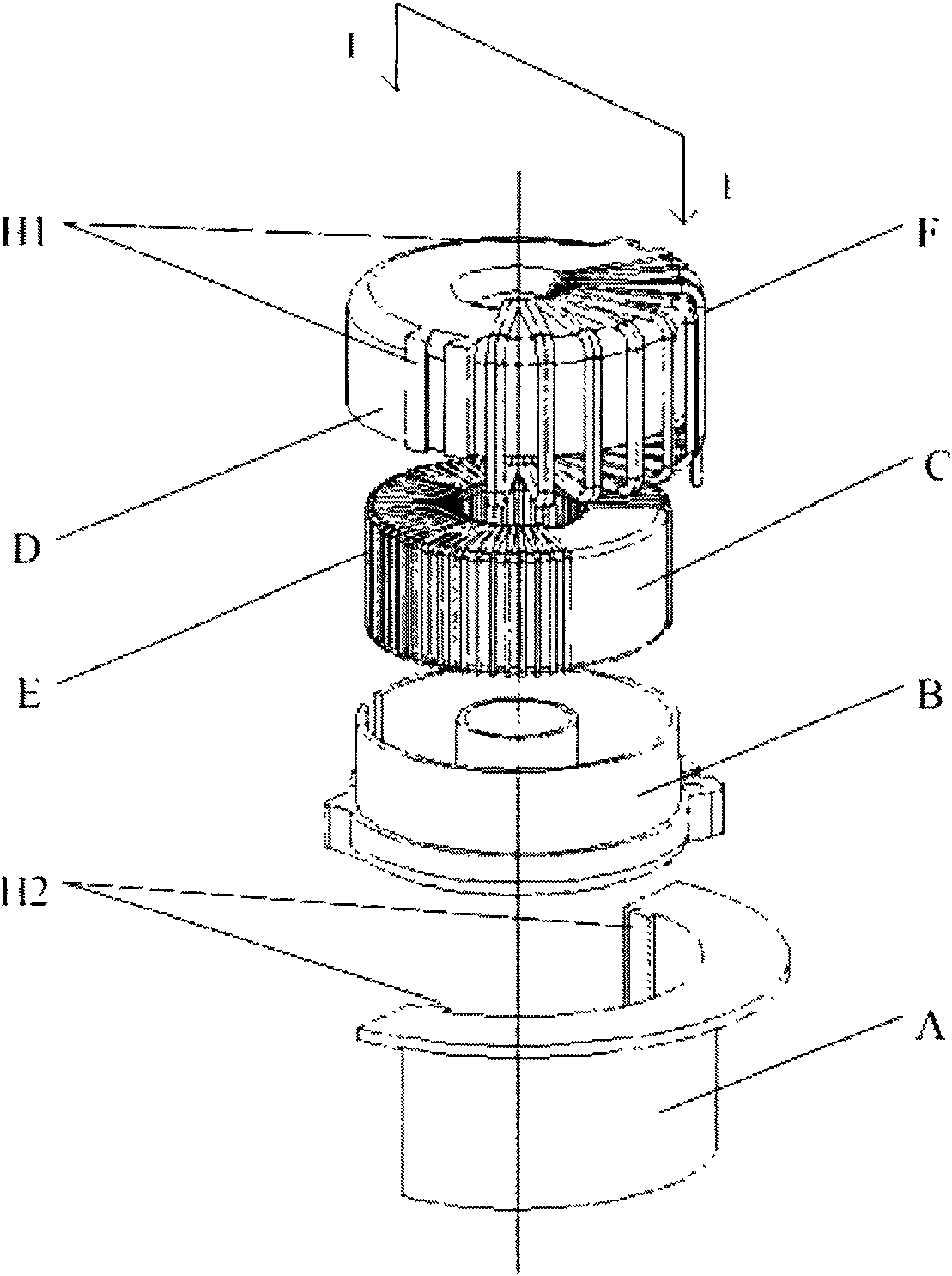

[0027] exist figure 1 An exploded view of a toroidal transformer according to an embodiment of the present invention, such as a toroidal transformer for driving devices for low-voltage halogen lamps and LEDs, is shown in . figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com