Imaging device and camera module

A technology for imaging devices and camera modules, which can be applied to electric solid-state devices, semiconductor devices, electrical components, etc., can solve problems such as thermal deformation of chips, and achieve the effect of suppressing flash.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Embodiments of the present disclosure are described below with reference to the drawings.

[0039] Description will be given in the following order.

[0040] 1. First structure example of imaging device

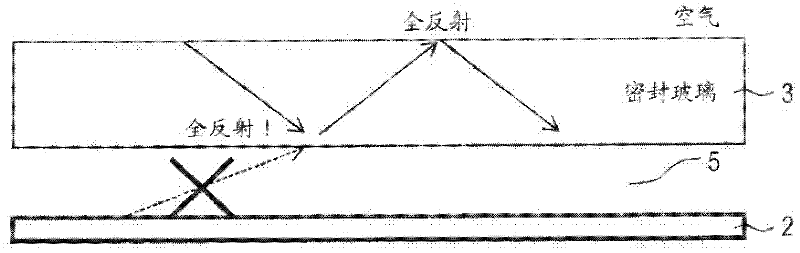

[0041] 2. Control the basic structure and function of the film (multilayer film)

[0042] 3. Control the specific structure and function of the film (multilayer film)

[0043] 4. Typical structure and function of control film (multilayer film)

[0044] 5. Second structure example of imaging device

[0045] 6. Structure example of camera module

[0046]

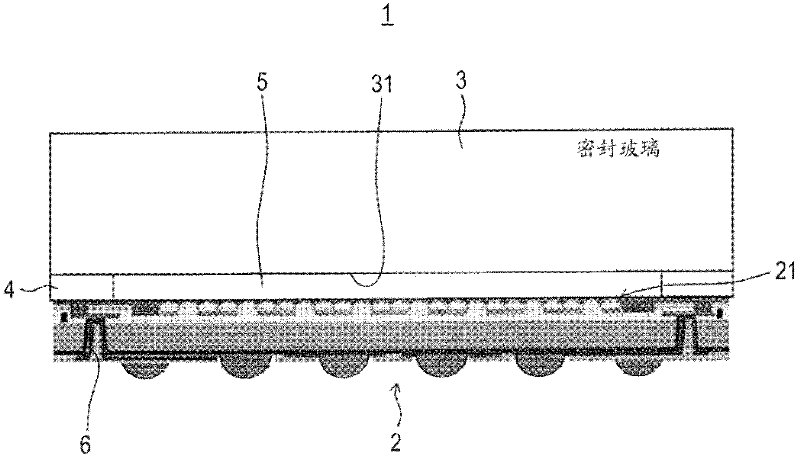

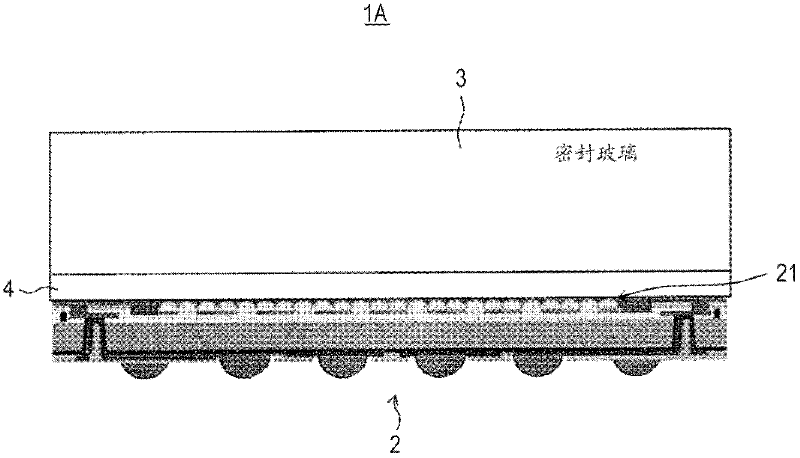

[0047] Figure 5 is a view showing a first structural example of the imaging device according to the embodiment.

[0048] In this embodiment, a CMOS image sensor (CIS) is used as an example of an optical sensor.

[0049] The imaging device 100 according to this embodiment mainly has a CSP structure in which the chip size of the optical sensor is packaged, and a cavity-less CPS structure without gaps in which t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com