Method of manufacturing solid-state imaging element, solid-state imaging element and electronic apparatus

A technology of solid-state imaging components and manufacturing methods, which can be applied to electric solid-state devices, radiation control devices, electrical components, etc., and can solve problems such as chip cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-2

[0084] 3. Embodiment 1-2 (an example of bending an imaging chip by gas volume contraction)

Embodiment 1-3

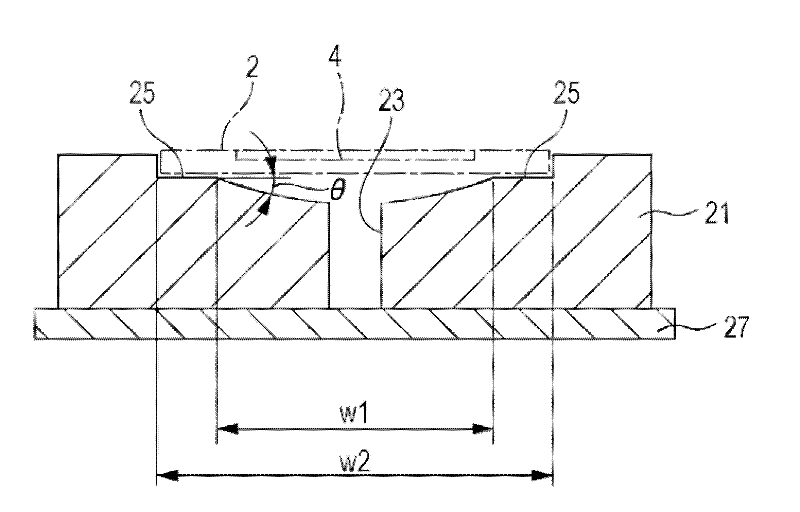

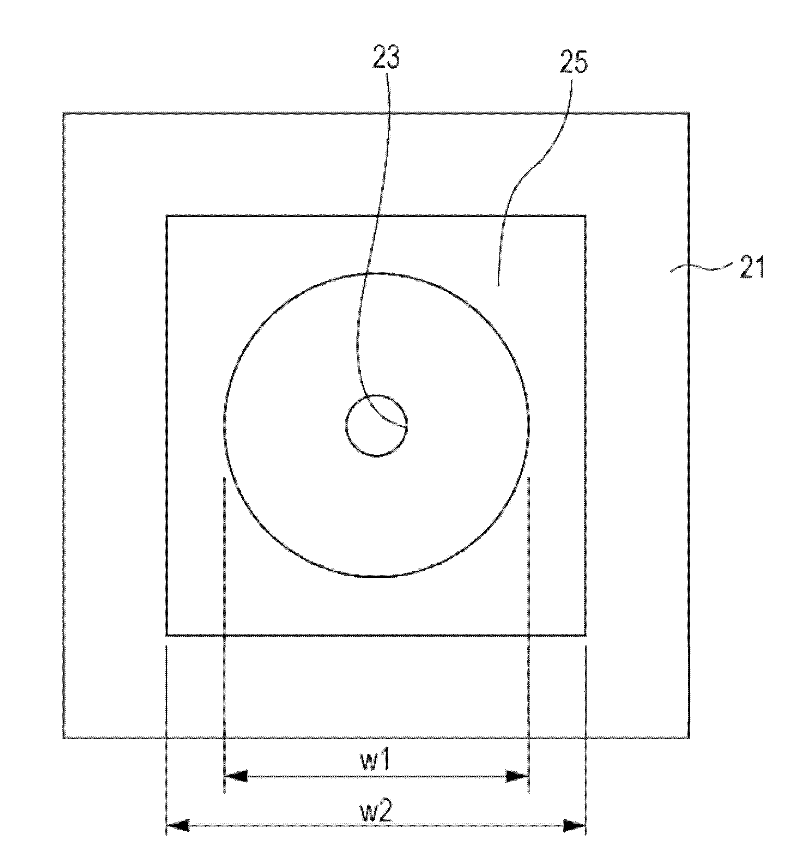

[0085] 4. Embodiments 1-3 (example using a base as a package)

[0086] 5. Embodiments 1-4 (Example of fixing the imaging chip to the base by vacuum adsorption)

[0087] 6. Example 2-1 (example of bending an imaging chip by curing shrinkage of resin)

Embodiment 2-2

[0088] 7. Embodiment 2-2 (example of bending the imaging chip by negative pressure)

[0089] 8. Embodiment 2-3 (Example using a base as a package)

[0090] 9. Embodiment 2-4 (Example of fixing the imaging chip to the base by vacuum adsorption)

[0091] 10. Embodiment 2-5 (example of controlling the shape of the curved part according to the shape of the base)

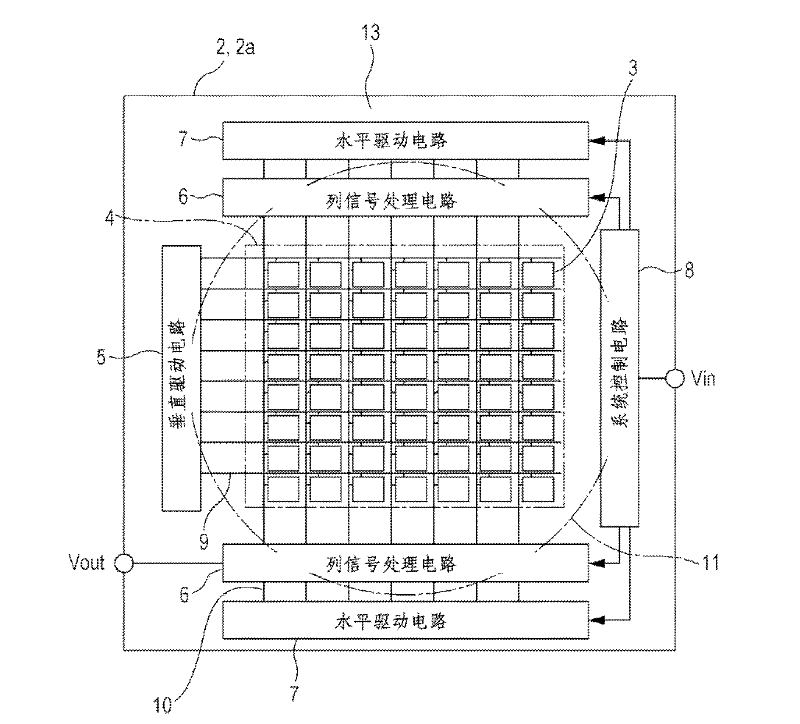

[0092] 11. Schematic structural example of a solid-state imaging chip applied to the present invention

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com