Multi-vibrator Rotary Piezoelectric Motor

A piezoelectric motor, rotary type technology, applied in the direction of piezoelectric effect/electrostrictive or magnetostrictive motors, generators/motors, electrical components, etc., can solve the problem of small output power and torque, limited commercialization and practical issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

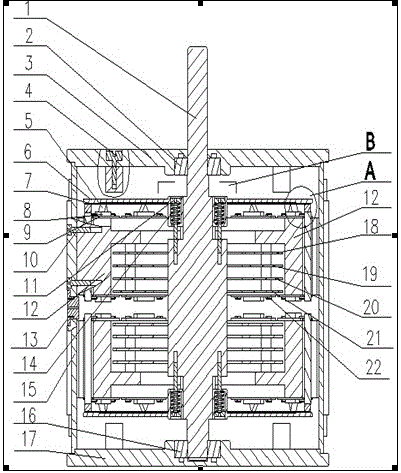

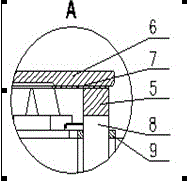

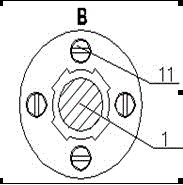

[0066] Example 1 as figure 1 As shown, a multi-vibrator rotary piezoelectric motor provided by the present invention includes an upper end cover (3), a lower end cover (17), a cooling case (15), a transmission shaft (1), and more than one piezoelectric power unit The upper end cover (3), the lower end cover (17) are connected with the heat dissipation casing (15) respectively, the upper end of the transmission shaft (1) passes through the upper bearing (2) and is connected with the upper end cover (3), and the lower end of the transmission shaft (1) is placed Connect with the lower end cover (17) in the bearing (16);

[0067] The piezoelectric power unit is assembled from a stator unit, a rotor unit, a preload unit and a frequency tracker; the piezoelectric power units are all axially and sequentially installed on the transmission shaft (1 ), and then placed in the cooling case (15); the piezoelectric power unit drives the transmission shaft (1) to rotate through the rotor (6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com